F118 IN-CEILING MEDIA AIR CLEANER

68-0209-2 Revised 11-07

2

ORDERING INFORMATION

If you have additional questions, need further information, or would like to comment on our products or services, please write or

phone:

1.

Your local Honeywell Commercial Air Products Distributor.

2.

Air-Pure Systems

16873 Fish Point Rd. SE

Prior Lake, MN 55372-1714

Phone: (800) 998-1919

Fax: (800) 221-3248

SPECIFICATIONS

IMPORTANT

The specifications given in this publication do not

include normal manufacturing tolerances. Therefore,

this unit may not exactly match the listed specifica-

tions. Also, this product is tested and calibrated

under closely controlled conditions, and some minor

differences in performance can be expected if those

conditions are changed.

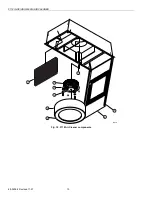

Color:

Galvanized steel cabinet and white cover.

Blower/Motor:

Three-speed direct-drive forward curve. Motor

lubrication is not required.

Ambient Temperature Rating:

Shipping and Storage: -20°F to +150°F ( -29°C to +66°C).

Operating: Ambient temperatures usually below 77°F (25°C)

but occasionally as high as 104°F (40°C).

Humidity:

Up to 95% relative humidity, non-condensing.

Air Volume:

Electrical Ratings:

Grille Type:

Perforated metal.

Dimensions:

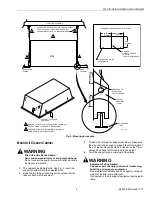

Fig. 1. Approximate dimensions of F118 in in. (mm).

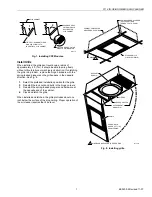

Mounting:

Hangs freely from structural ceiling.

Can be recessed into a drop ceiling frame.

Weight:

Shipping (Cabinet and Contents): 119 lb (54 kg).

Installation: 92 lb (42 kg).

CPZ™ Adsorbent Module: 8 lb (3.6 kg) each.

Module Total Weight: 10 lb. (4.5 kg) each.

Sound Level at 3.3 ft (1m):

High Speed: 65 dBA.

Medium Speed: 54.5 dBA.

Low Speed: 48 dBA.

Operation at low and medium speeds is within white noise

range.

Approvals:

UL: Listed.

CSA: Certified.

CE: Pending.

Replacement Parts:

See the Parts List section.

120V

230V

High

425 cfm, 723 m

3

/hr

400 cfm, 680 m

3

/hr

Medium

300 cfm, 510 m

3

/hr

320 cfm, 544 m

3

/hr

Low

200 cfm, 340 m

3

/hr

220 cfm, 374 m

3

/hr

Current Draw

120V

230V

High

2.8A

1.6A

Medium

2.0A

0.8A

Low

1.4A

0.5A

12-1/2

(317)

1 (25) CLEARANCE

OF DROP CEILING

47-3/4

(1213)

23-1/2

(597)

VIEW UNDERSIDE

(GRILLE REMOVED)

POWER CONNECTOR

(ELECTRICAL BOX)

M16213

SUPPORT RODS

PRE-FILTER (WRAPS)

PARTICULATE FILTER