F118 IN-CEILING MEDIA AIR CLEANER

68-0209-2 Revised 11-07

6

5.

Standing on a secure platform, lift the cabinet body and

insert it into the frame in the drop ceiling.

6.

Attach the free end of the wire to the structural ceiling.

Align the cabinet edge with the upper side of the T-bars,

without releasing the full weight onto the T-bars.

7.

Verify that the wire is strong enough to bear the load of

the F118 before completing installation.

8.

Level the air cleaner.

Electrical Hookup

All wiring must comply with applicable codes and ordinances.

The air cleaners are internally pre-wired.

IMPORTANT

Check that the air cleaner is grounded for proper

operation and safety.

Canadian Installations: Do not install in ceilings

with thermal insulation value greater than R-40.

If installing an additional wall switch to regulate the air cleaner

speed, only the Honeywell 32000234 (41105) Variable Speed

Switch (optional) is recommended. Using a different speed

controller can void the warranty.

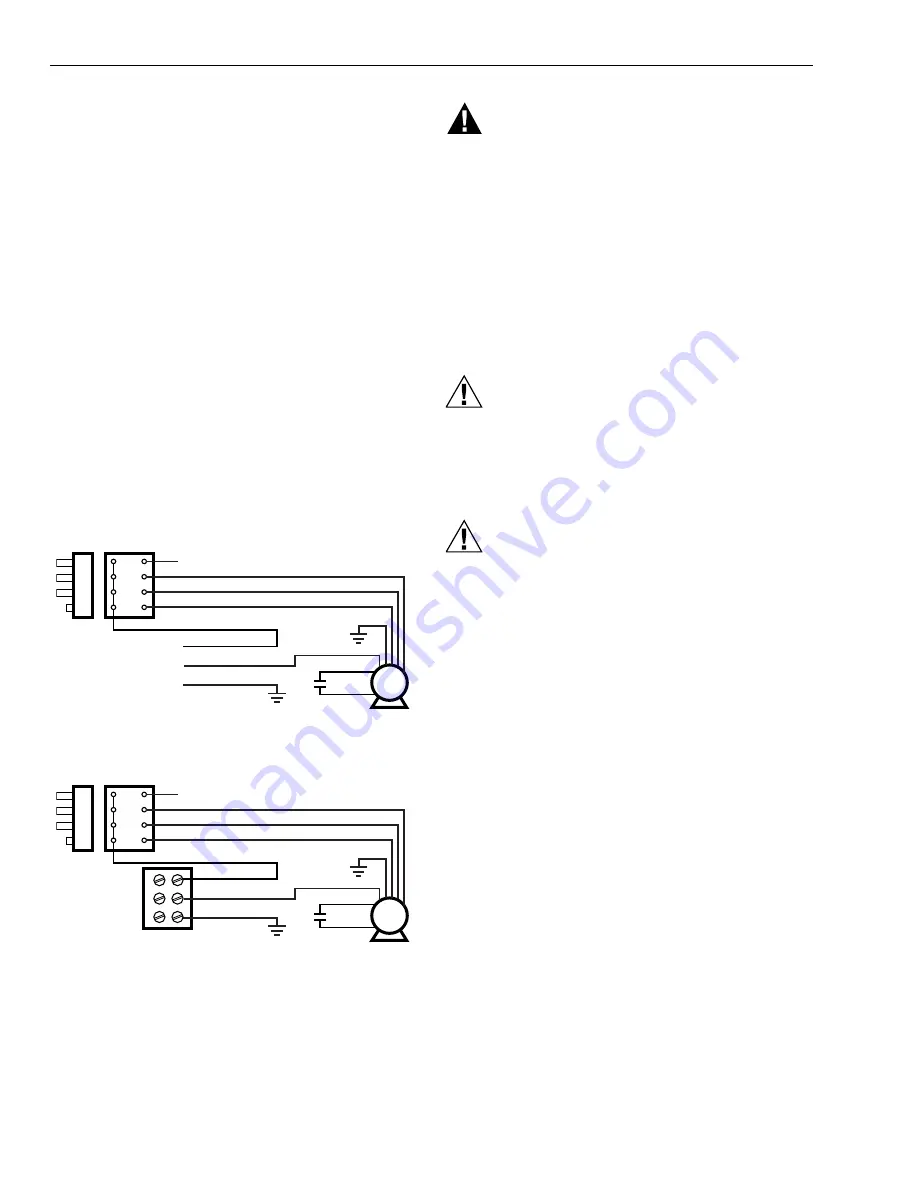

1.

Pull the wire to the electrical box through the hole in the

top of the cabinet. Refer to Fig. 5 and 6 for typical wiring

diagrams.

Fig. 5. Typical F118 120V, 60 Hz Wiring Diagram.

Fig. 6. Typical F118 230V, 50 Hz Wiring Diagram.

WARNING

Fire or Electric Shock Hazard.

Can cause personal injury or equipment damage.

Be careful performing electrical check when air

cleaner is turned on.

Be careful when working near air cleaner moving

parts.

2.

Turn on air cleaner power and check for proper opera-

tion for two to three minutes. There should be a smooth,

powerful blower sound with air discharging from both

ends of the air cleaner.

3.

Turn off the power.

Install Filters

CAUTION

Eye Exposure.

Harmful dust can obstruct or injure unshielded

eyes.

CPZ module normally releases dust when handled.

Always wear safety glasses when installing or remov-

ing CPZ module.

CAUTION

Filter Media Damage Hazard.

Damage to the filter media can easily occur.

Do not touch the pleated filter media.

Handle only the filter frame.

1.

Install the particle filter and pre-filter that is wrapped

around the particle filter:

a. Push aside the support rods.

b. With both hands, slide the filter up into the central

portion of the cabinet and hold it in place.

c. Pull the support rods down and toward the center,

until the filters are held in place and the weight com-

pletely supported.

IMPORTANT

Avoid excessive pressure on individual adsorbent

panels.

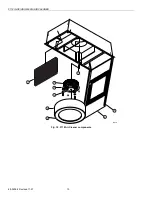

1.

Install the CPZ sorbent modules:

a. Remove CPZ™ sorbent modules from the packag-

ing.

b. See Fig. 7 to install CPZ module at each end of the

cabinet. Tilt and then push the module up about ten

inches into the opening. Then allow it to rotate down

so the bottom rests on the inside cabinet ledge.

ON

HI

MED

LO

1

2

3

4

BLACK

BLUE

RED

GREEN

ORANGE

YELLOW

BLACK

WHITE

GROUND GREEN

INPUT:

HIGH SPEED 2.8A AT 120V - 60 HZ

MED SPEED 2.0A AT 120V - 60 HZ

LOW SPEED 1.4A AT 120V - 60 HZ

FAN MOTOR

M16210A

ON

HI

MED

LO

1

2

3

4

BLACK

BLUE

RED

GREEN

ORANGE

YELLOW

BROWN

BLUE

GREEN/YELLOW

INPUT:

HIGH SPEED 2.8A AT 230V - 50 HZ

MED SPEED 2.0A AT 230V - 50 HZ

LOW SPEED 1.4A AT 230V - 50 HZ

FAN MOTOR

M14417