EN - 7

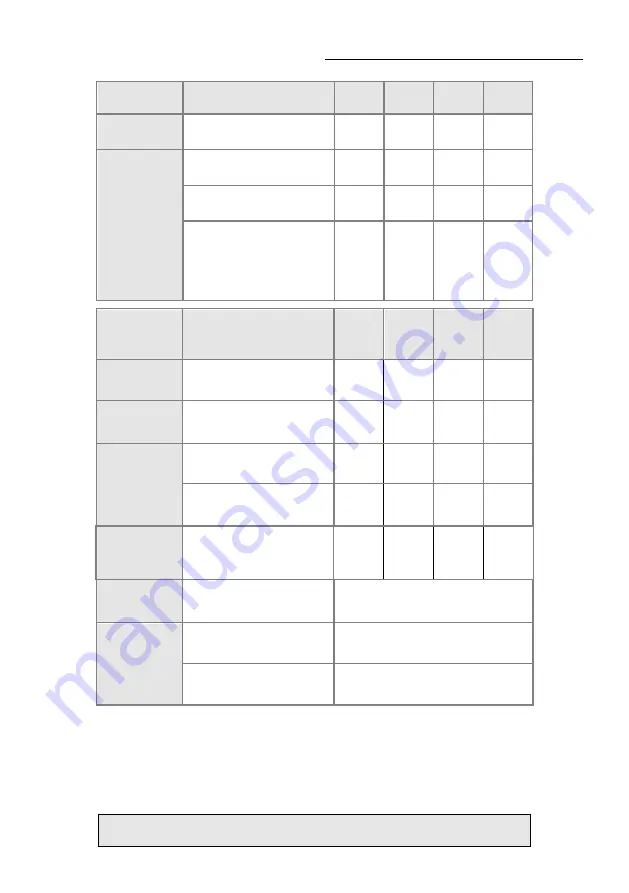

FREQUENCY OF MAINTENANCE AND INSPECTION OPERATIONS

All the apparatuses must undergo the following inspections

COMPONENTS

Type of work required

Before

use

After

use

Every

six

months

Every

year

Mask

Clean and disinfect

(See mask's instructions for use)

X

X(3)

Full SCBA

Cleaning

X

X(4)

Test on bench

X(2)

X(1)

X

Checks by the user:

- all connectors are correctly

tightened (high pressure, medium

pressure, hoses, etc.)

- the shoulder straps are in good

condition

- the apparatus is operating

X

X

COMPONENTS

Type of work to be done by a

specialised maintenance

workshop

Every

year

Every

2 years

Every

6 years

Every

10 years

Mask

Replace:

- inhalation/exhalation valves

- seals

X

X(3)

Demand valve

Replace:

- diaphragm

- spring

- valve

X (1)

X

Pressure reducer

manifold

Replace:

- seal

- piston

X (1)

X

Replacement of the high pressure

connector seal

X

Medium pressure

flexible hose

fitted with a self-

sealing inlet

connector

Replace:

- seal

X (1)

X (1)

Compressed air

cylinder

Regular inspection and

requalification by an approved

body

Refer to and follow the national regulations

applicable to compressed air reserves

Cylinder valve

collector

Replace:

- seal

- closure member

Once every 5 years or more often

Replace:

- Break seal

At least once every 12 months

X)

Required

1)

For breathing apparatus used frequently or regularly with medium pressure flexible hoses connected to external sources of medium

pressure air

2)

After use in aggressive environments or extreme conditions

3)

For reserve stocks

4)

Not if the apparatus is hermetically packaged

Note: For more information about the composition of kits, see the spare parts price list or contact HONEYWELL RESPIRATORY

SAFETY PRODUCTS.

Inspect the apparatus fully (working and sealing) after each change of spare parts.

Some parts have screws sealed using red varnish to certify that the parts were fitted at

HONEYWELL RESPIRATORY SAFETY PRODUCTS. The manufacturer is not liable for incorrect

operation of any part that no longer bears this seal.