[7] FIELD WIRING; INSTALLATION GUIDELINES

All wiring must be installed in compliance with the National Electrical Code

and the local codes having jurisdiction. Proper wire gauges should be used.

The conductors used to connect smoke detectors to control panels and acces-

sory devices should be color-coded to prevent wiring mistakes. Improper con-

nections can prevent a system from responding properly in the event of a fire.

For signal wiring (the wiring between detectors or from detector to auxiliary

devices), it is usually recommended that single conductor wire be no smaller

than 18 gauge. The duct smoke detector terminals accommodate wire sizes up

to 12 gauge. Flexible conduit is recommended for the last foot of conduit; solid

conduit connections may be used if desired.

Duct smoke detectors and alarm system control panels have specifications for

Signaling Line Circuit (SLC) wiring. Consult the control panel manufacturer’s

specifications for wiring requirements before wiring the detector loop.

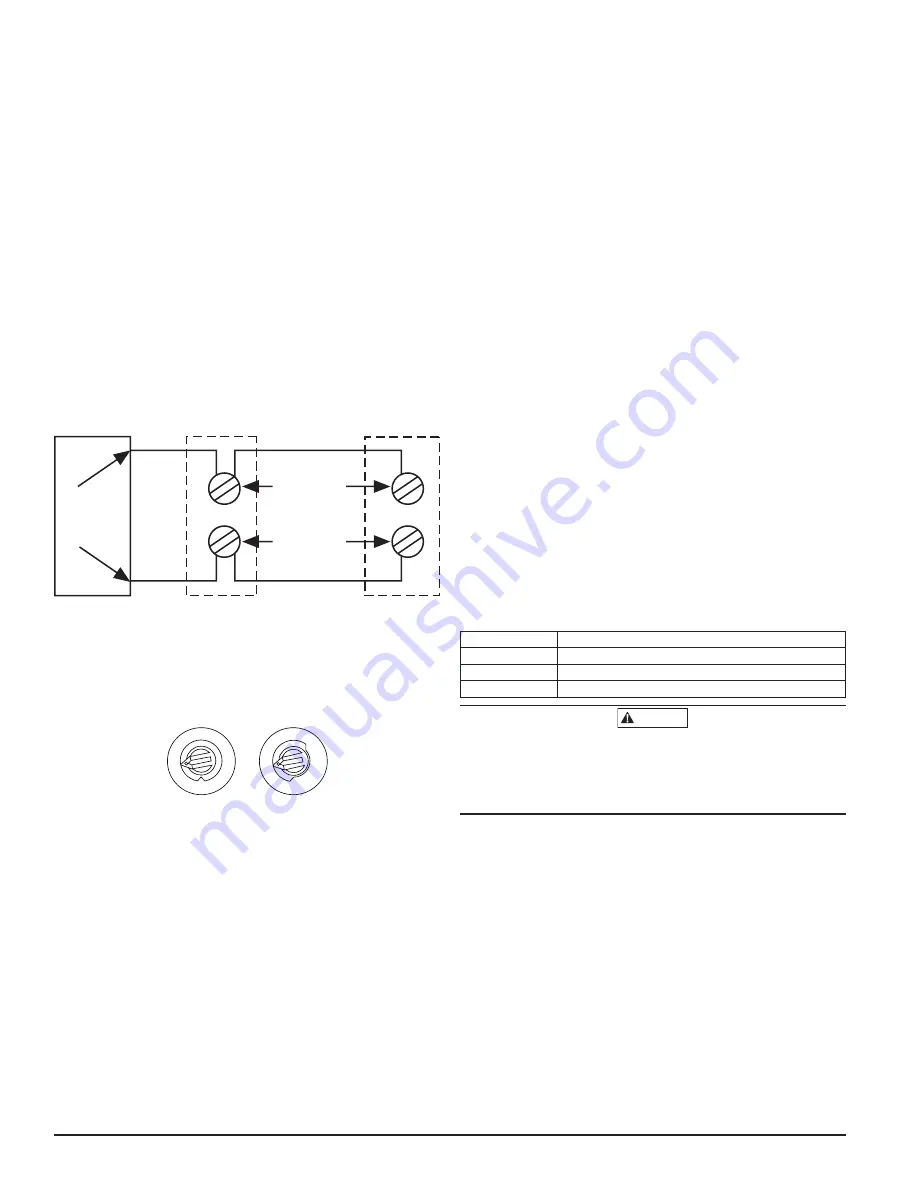

[7.1] WIRING INSTRUCTIONS

Disconnect power from the communication line before installing the D365PL

duct smoke detector.

The D365PL detectors are designed for easy wiring. The housing provides a

terminal strip with clamping plates. Wiring connections are made by sliding

the bare end under the plate, and tightening the clamping plate screw. See

Figure 6 below for system wiring.

FIGURE 6. SYSTEM WIRING DIAGRAM FOR D365PL

COMM.

LINE (+)

UL/FM LISTED

CONTROL

PANEL

1ST

DETECTOR

IN LOOP

2ND

DETECTOR

IN LOOP

COMM.

LINE (–)

COMM.

LINE

HO572-00

[7.2] SET THE ADDRESS

Set the desired address on the sensor head code wheel switches on the back

of the sensor head.

FIGURE 7. ROTARY ADDRESS SWITCHES

TENS

ONES

9

10

11

12

13

14

15

8

7

6

5

4

3

2

1 0

9

8

7

6

5

4

3

2

1 0

C0162-00

[8] VERIFICATION OF OPERATION

[8.1] INSTALL THE COVER

Install the covers making sure that the cover fits into the base groove. Tighten

the seven screws that are captured in the covers. Note that the cover must be

properly installed for proper operation of the sensor.

[8.2] POWER THE UNIT

Activate the communication line on terminals COM + and COM –.

[8.3] DETECTOR CHECK

Standby – If programmed by the system control panel, look for the presence of

the flashing LEDs through the transparent housing cover. The LED will flash

with each communication.

Trouble – If programmed by the system control panel and the detector LEDs

do not flash, then the detector lacks power (check wiring, missing or improp-

erly placed cover, panel programming, or power supply), the sensor head is

missing (replace), or the unit is defective (return for repair).

[8.4] DUCT SMOKE DETECTOR TEST & MAINTENANCE PROCEDURES

Test and maintain duct smoke detectors as recommended in NFPA 72. The

tests contained in this manual were devised to assist maintenance personnel

in verification of proper detector operation.

Before conducting these tests, notify the proper authorities that the smoke

detection system will be temporarily out of service. Disable the zone or system

under test to prevent unwanted alarms.

[8.4.1] TEST THE UNIT

1. M02-04-00 Magnet Test (not included) – This sensor can be function-

ally tested with a test magnet. The test magnet electronically simulates

smoke in the sensing chamber, testing the sensor electronics and connec-

tions to the control panel.

2. Remote Test Accessory – The use of a remote accessory for visible indica-

tion of power and alarm is recommended.

Verify system control panel alarm status and control panel execution of

all intended auxiliary functions (i.e. fan shutdown, damper control, etc.).

Two LEDs on the sensor are controlled by the panel to indicate sensor

status. Coded signals, transmitted from the panel, can cause the LEDs

to blink, latch on, or latch off. Refer to the control panel technical docu-

mentation for sensor LED operation and expected delay to alarm.

[8.4.2] THE DETECTOR MUST BE RESET BY THE SYSTEM CONTROL

PANEL

[8.4.3] SMOKE ENTRY TEST USING AEROSOL SMOKE

This test is intended for low-flow systems (100-500 FPM). If the air speed is

greater than 500 FPM, use a conventional manometer to measure differential

pressure between the sampling tubes, as described in Section 6 Measurement

Tests.

Drill a ¼-inch hole 3 feet upstream from the duct smoke detector. With the air

handler on, measure the air velocity with an anemometer. Air speed must be

at least 100 FPM. Spray aerosol smoke* into the duct through the ¼-inch hole

for five seconds. Wait two minutes for the duct smoke detector to alarm. If the

duct smoke detector alarms, air is flowing through the detector. Remove the

duct smoke detector cover and blow out the residual aerosol smoke from the

chamber and reset the duct smoke detector at the panel. Use duct tape to seal

the aerosol smoke entry hole. Remember to replace the cover after the test or

the detector will not function properly.

Additionally, canned aerosol simulated smoke (canned smoke agent) may be

used for smoke entry testing of the smoke detector. Tested and ap proved aero-

sol smoke products are:

Manufacturer

Model

HSI Fire & Safety 25S, 30S (PURCHECK)

SDi

SMOKE CENTURIAN, SOLOA4, SMOKESABRE, TRUTEST

No Climb

TESTIFIRE 2000

CAUTION

Canned aerosol simulated smoke (canned smoke agent) formulas will vary

by manufacturer. Misuse or overuse to these products may have long term

adverse effects on the smoke detector. Consult the canned smoke agent manu-

facturer’s published instructions for any further warnings or caution state-

ments.

4

I56-6626-000

2/26/2019