4. Set Up and Calibration Procedures - Lock Set Up Group

Revision 5

10260S HercuLine® Actuator Installation, Operation and Maintenance Manual

47

7/07

Lower Display

Prompt

Upper Display

Selections or

Range of Setting

Parameter Definition

UNITS

SI

ENGL

DISPLAY UNITS

—Selects standard for unit values for the

local display.

SI

—Display will show unit values in international (metric)

units. (Temperature in degrees C, Date format:

ddmmyy

)

English

—Display will show unit values in U.S. units.

(Temperature in degrees F, Date format:

mmddyy

)

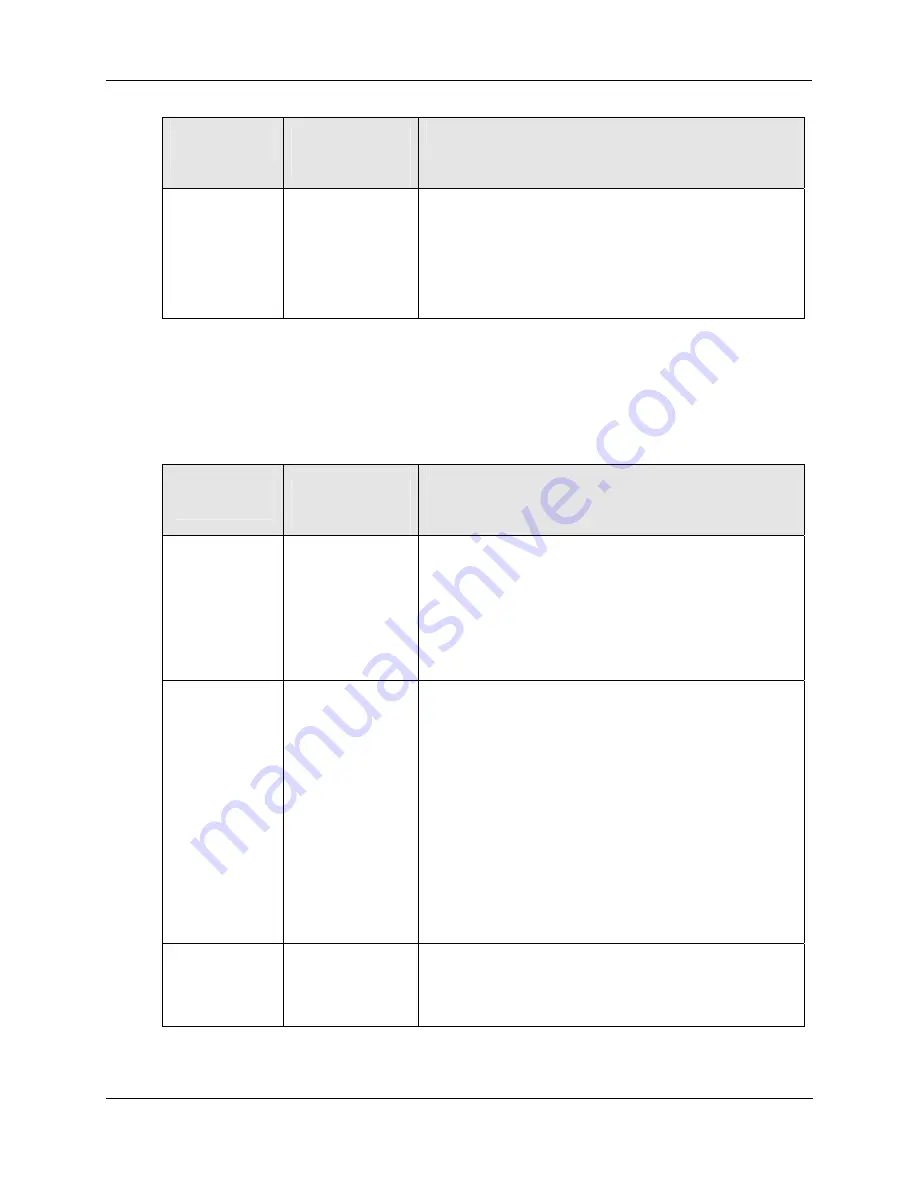

Lock Set Up Group

Table 17 lists the parameters and selections available for the SET LOCK group.

Table 17 Lock Set Up Group Parameters

Lower Display

Prompt

Upper Display

Selections or

Range of Setting

Parameter Definition

LOCKID

Nnnn

n

= 1 to 9

(Up a limit of 4095)

PASSWORD LOCK

—4-digit password can be selected to

provide security access to calibration information, set up

parameters and supervisory functions. Password can be a

number from 0 to 4095.

A password is required in order to change the lock

parameter.

See “

Set/Change Password”

below.

LOCK

NONE

[default]

CAL

CONF

FULL

LOCK OUT FEATURE

—Selects lockout security for

calibration and supervisory functions, and set up groups.

None

—No lockout of any calibration or set up groups. You

select and change set up group values, and perform field

calibration.

Calibration

—Lockout for calibration groups SET CALIN,

SET CALMTR, SET CALOUT and CAL NCSOUT only. You

can select and change set up group values.

Configuration

—Lockout for calibration groups and set up

group configuration. You can only scroll through and view

set up group values.

Full

—Lockout for calibration and all set up group values.

Only SET LOCK and READ STATUS groups are accessible.

MAENAB DIS

[default]

ENAB

AUTO / MANUAL MODE LOCKOUT --

DIS

—disables the mode key on the keypad.

ENAB

—enables the mode key on the keypad.

Summary of Contents for HercuLine 10260S

Page 10: ......

Page 94: ......

Page 121: ......

Page 122: ...Honeywell Field Solutions Honeywell Inc 512 Virginia Drive Fort Washington PA 19034 ...