Rev A

12

Document 800-04354

04/09

6.

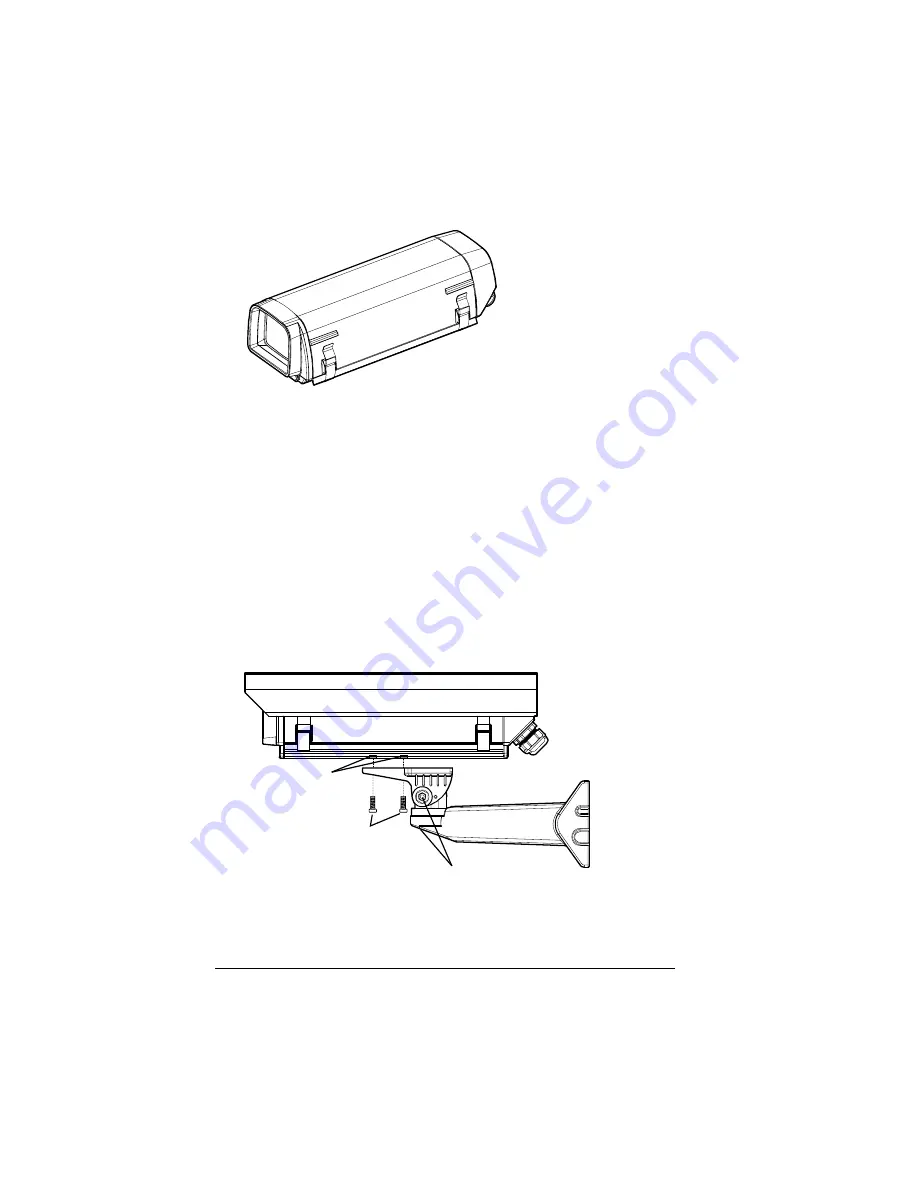

Reassemble the housing unit by closing the upper body and latching the lid tight.

7.

If applicable, reinstall the sunshield by sliding it across the top of the housing.

Mounting the Wall Bracket

To mount the wall bracket:

1.

Use fasteners of an appropriate size and type to attach the bracket to the wall

surface. Position the housing so that it allows for viewing the selected area.

2.

Locate the two nuts that freely slide along the channel. Position the nuts

approximately 2 inches from each other.

3.

Place the housing onto the mount, aligning the holes. Insert the two 1/4"-20 UNC

screws (supplied) through the mount and into the nuts and tighten to secure the

assembly.

4.

Adjust the moveable arm of the wall bracket to attain the desired position.

5.

Tighten the bolt located at the pivot point of the moveable arm and tighten the set

screw.

6. Latch the lid.

2. Position the

two nuts 2”

apart.

3. Secure the housing with

2 x 1/4 x 20 UNC screws.

4. Adjust the arm,

then tighten the

set screws.

1. Attach the

bracket to the

wall using 4

sheet metal

screws.