HM700A1000

5

33-00118—01

Table 4. Steam humidifier(s) necessary for application.

a

a

In the table above,

11 GPD

indicates a steam humidifier configured to run on 120 V and

22 GPD

indicates a steam humidifier

configured to run on 240 V.

LOCATION

Mount on a suitable wall or vertical surface. Do not sit the unit

on the floor. Allow clearances required for plumbing and

electrical connections. Clearance dimensions shown are for

reference only and are the minimum required for maintenance

of the humidifier. Consult local and national codes before final

location and installation. Honeywell does not accept

responsibility for installation code violations.

• Install only in areas with ambient temperature 41 to 104 °F

(5 to 40 °C) and relative humidity 5 to 95 %.

• When possible install below the steam distributor. Take

care to provide proper steam line routing and proper

condensate traps.

• DO NOT locate the humidifier any further then absolutely

necessary from the steam distributor location as net output

will be reduced as a result of heat loss through the steam

line.

• When possible, mount the HM700 humidifier at a height

convenient for servicing.

NOTE: Do not mount on hot surfaces, where freezing

can occur, vibrating surface, or floor.

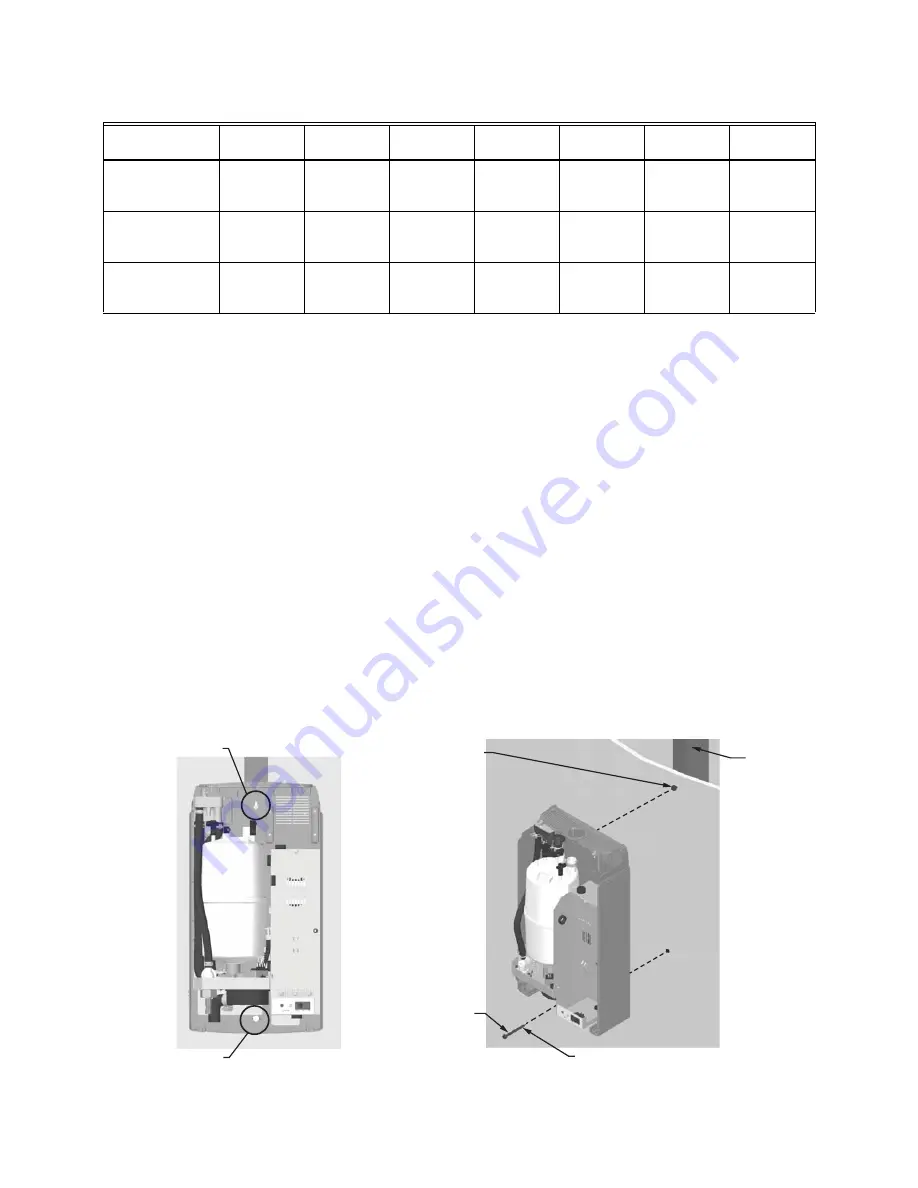

Mounting with Keyholes

1.

The HM700 humidifier is wall mounted using a keyhole

located on the back of the unit cabinetry.

2.

Use #8 x 2 in. (5 cm) screws mounted into 2x4 studs or

better. 2 screws are needed, one for hanging the unit

and one for securing so it will not lift off the keyhole.

3.

Install the top screw so that 1/4 in. (6 mm) is exposed.

Raise the unit and place the screw head through the

keyhole.

4.

Make sure the unit is level and then insert and tighten

the second screw through the bottom hole. Tighten the

top screw. See Fig. 3.

NOTE: Use screws longer than 2 in. (5 cm) if drywall or

other spacer is present.

Fig. 3. Mounting with keyholes.

Construction

Type

8,000 ft

3

12,000 ft

3

16,000 ft

3

20,000 ft

3

24,000 ft

3

28,000 ft

3

32,000 ft

3

Tight

11 GPD

11 GPD

11 GPD

11 GPD

11 GPD

11 GPD (x2)

or

22 GPD (x1)

11 GPD (x2)

or

22 GPD (x1)

Average

11 GPD

11 GPD

22 GPD

22 GPD

22 GPD

11 GPD (x3)

or

22 GPD (x2)

11 GPD (x3)

or

22 GPD (x2)

Loose

22 GPD

22 GPD

22 GPD

11 GPD (x3)

or

22 GPD (x2)

11 GPD (x3)

or

22 GPD (x2)

11 GPD (x4)

or

22 GPD (x2)

11 GPD (x5)

or

22 GPD (x3)

INSTALL SECOND

SCREW AFTER

HANGING

HUMIDIFIER

#8 X 2 IN. (5 CM)

WOOD SCREWS

INSERT SCREW LEAVING

1/4 IN. (6 MM) EXPOSED.

HANG UNIT, THEN

TIGHTEN SCREW.

2X4 OR OTHER

STRUCTURAL

MEMBER

KEYHOLE

M35759

HOLE

Summary of Contents for HM700A1000

Page 26: ...HM700A1000 33 00118 01 26 ...

Page 27: ...HM700A1000 27 33 00118 01 ...