Description

HON 670 / HON 671 Controllers Component Documentation

12

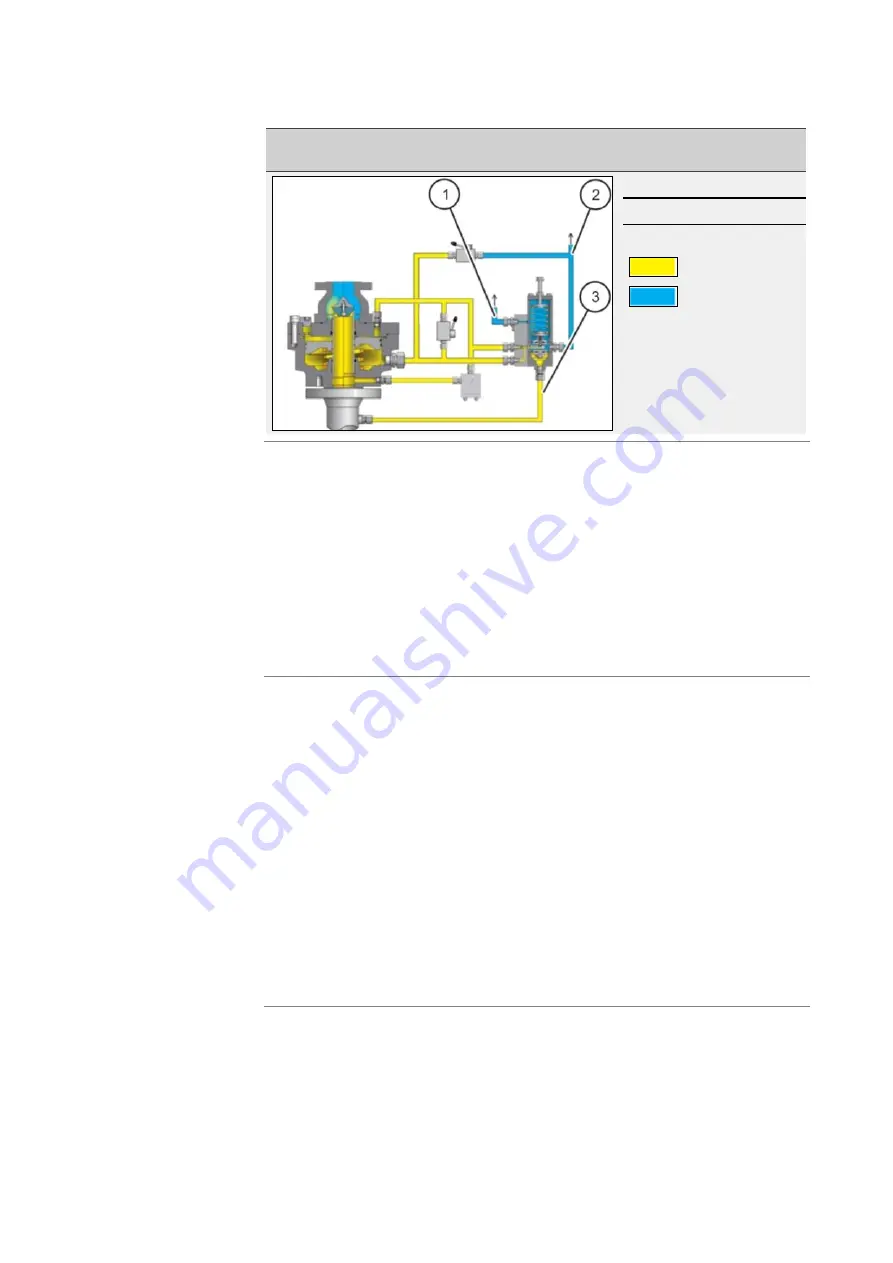

Figure

No. /

color

Description

1

Vent line

2

Bleed line

3

Measuring line

Outlet pressure

Atmospheric pres-

sure

▪

The pressure in the system to be safeguarded is guided into the controller via the

measuring line where it is applied to the upper side of the double diaphragm system

and compared with the reference variable that is specified using the setpoint adjusting

screw (force of the pilot spring).

▪

In the normal operating state, the amplifying valve is closed. The downstream system

including the actuator of the SAV is pressureless.

▪

When the upper or lower response pressure is reached, the amplifying valve opens.

▪

Gas from the monitored system flows to the actuator of the safety shut-off valve.

▪

The piston of the pressure unit is moved and triggers the SAV’s trip mechanism via the

piston rod.

▪

The safety shut-off valve closes.

▪

The pressure in the system to be safeguarded is guided into the controller via the

measuring line where it is applied to the upper side of the double diaphragm system

and compared with the reference variable that is specified using the setpoint adjusting

screw (force of the pilot spring).

▪

In the normal operating state, the amplifying valve is closed. The pressures in the upper

and lower actuator chamber of the actuator assembly are equal.

▪

When the monitored pressure reaches the set response pressure of the controller, the

amplifying valve opens.

▪

The pressure in the actuator chamber below the driving piston is reduced.

▪

The system pressure on the upper side of the actuator moves the sleeve against the

closing spring in the opening direction so that the blowdown procedure of the safety

relief valve is enabled.

▪

If the monitored pressure then once again falls below the setpoint as adjusted, the am-

plifying valve closes and the pressure in the lower actuator chamber thus rises.

▪

When the pressure between the upper and the lower actuator chamber has equalized,

the safety relief valve closes again on its own.

Functional diagram of the

controller

How the controller works

when the SAV responds

How the controller works

when the SBV responds