BAND

HUMIDISTATS

TYPICAL

PNEUMATIC

/ A S S E M B L Y

Follow steps through 4 of

Unhook the coil spring of the element assembly from

the

assembly bracket (Fig. IO).

Unhook the bias spring from its anchor post.

Remove the frame post and mounting screw.

Lift the nozzle/flapper assembly from the base.

Remove the O-ring from the rear of the nozzle/flapper

assembly.

Disengage the other end of the bias spring from the

bracket hole. Do not lose the small pin located inside

the spring.

Assemble the O-ring and the bias spring to the

replacement nozzle/flapper assembly and reinstall in

reverse order.

Recalibrate the

FILTER CARTRIDGE

Reinstall the tiumidistat cover.

AND

M

O

U

N

T

I

N

G

SCREWS (4)

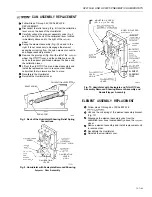

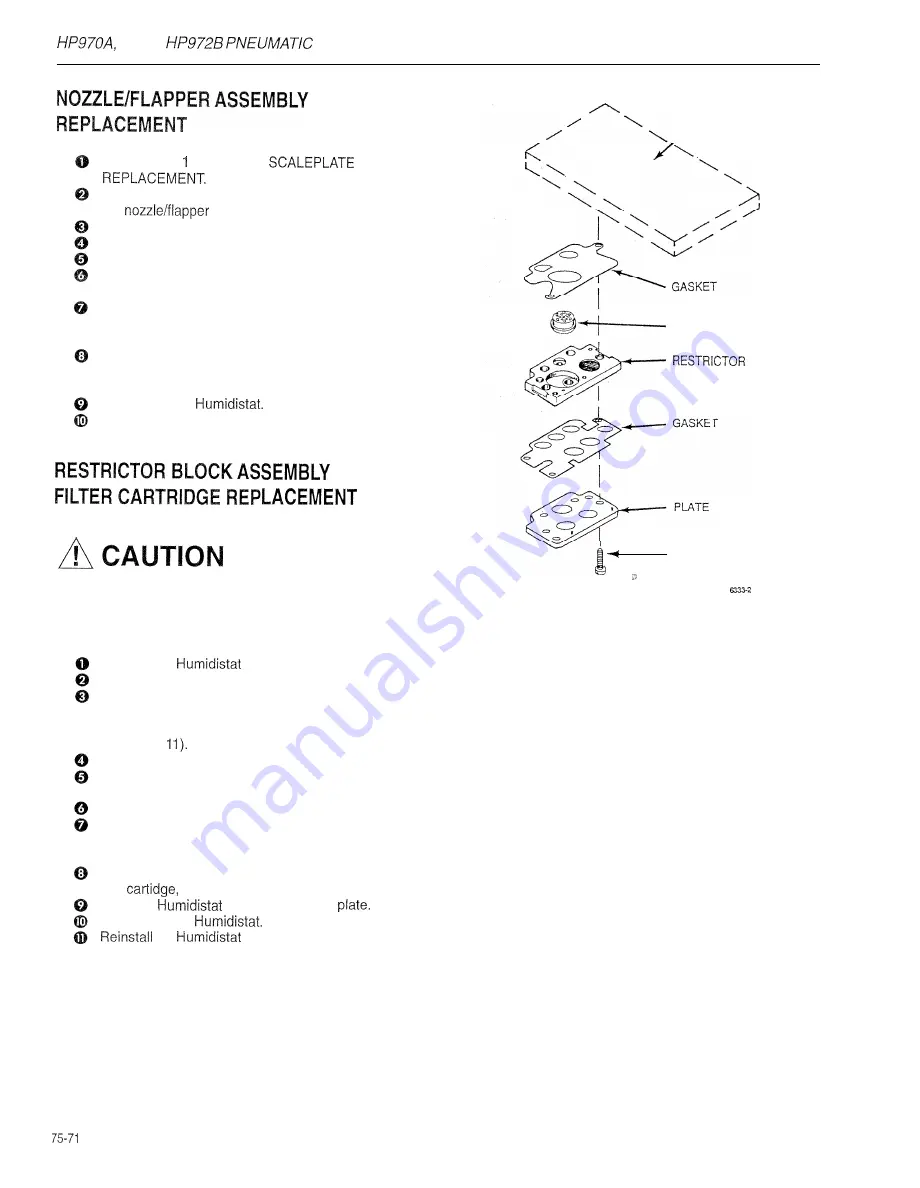

When replacing these parts, use extreme care to

prevent dirt, dust, or debris from entering various

openings of the Humidistat base or the restrictor

block.

Remove the

cover.

Remove the Humidistat.

Fig. Il. Restrictor Block Assembly and Filter

Cartidge Replacement.

Access to the restrictor block assembly and filter

cartridge is from the rear of the base assembly.

Remove the four mounting screws from the restrictor

block (Fig.

Carefully lift off the restrictor block (Fig. 11).

Remove the flat rubber gasket from the restrictor

block. The filter cartridge is located in the gasket.

Remove the filter cartridge from the gasket.

Align the gasket on the base assembly, and insert the

new filter cartridge into the recess in the base with the

screen end of the filter exposed.

Place the new restrictor block over the hasket and

filter

and replace the four mounting screws.

Snap the

onto the mounting

Recalibrate the

the

cover.

9.5