L7124U UNIVERSAL OIL ELECTRONIC AQUASTAT® CONTROLLER

5

69-1232—2

OPERATION

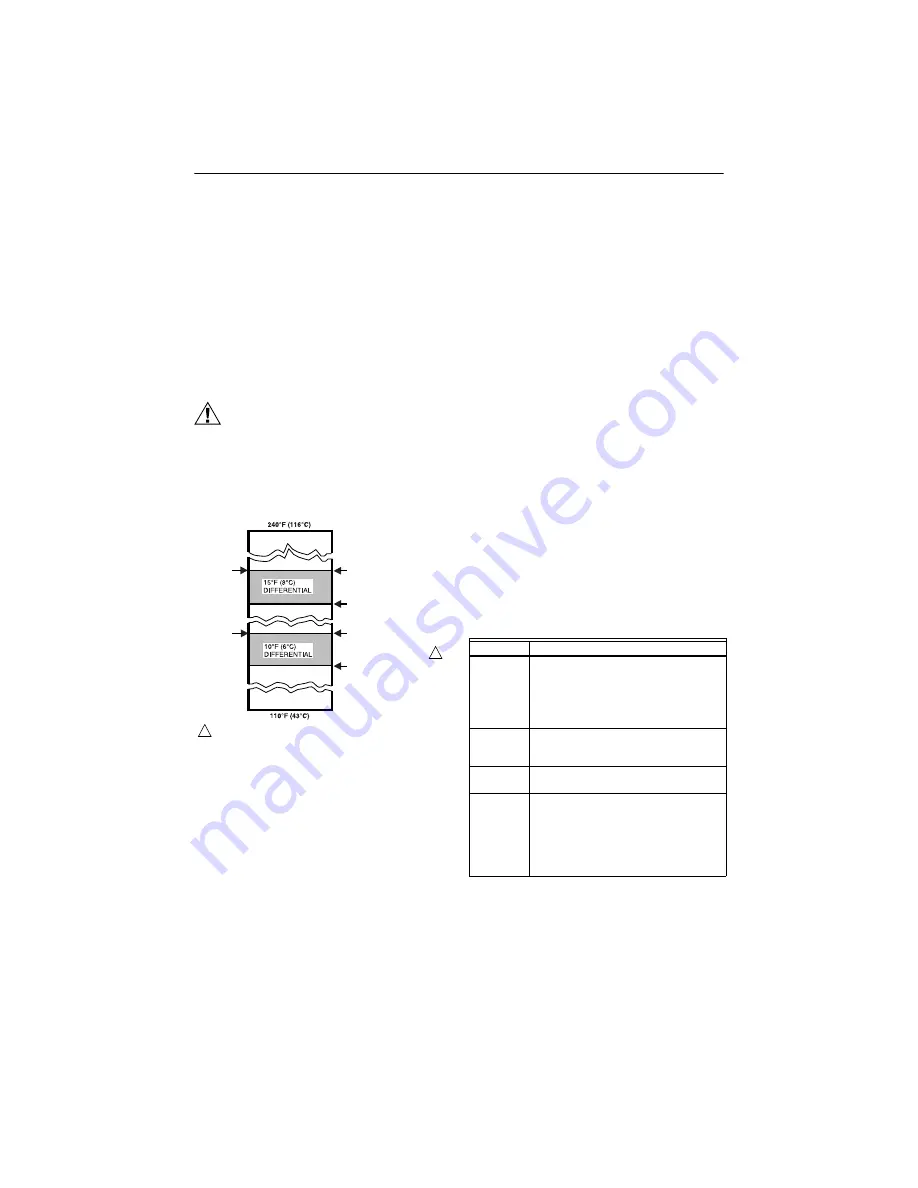

High Limit Controller

The high limit opens and turns off the burner when the

water temperature reaches the setpoint. The high limit

automatically resets after the water temperature drops

past the setpoint and through the 15°F (8°C) differential.

Low Limit and Circulator Controller

On a temperature rise, with the adjustable differential at

the minimum setting of 10°F (6°C), the burner circuit

breaks and the circulator circuit makes at the low limit

setpoint. On a temperature drop of 10°F (6°C) below the

low limit setpoint, the burner circuit makes and the

circulator circuit breaks. See Fig. 5.

CAUTION

Equipment Damage Hazard.

Can cause improper operation

1. Setting the Low Limit above the High Limit

disables the device.

2. Setting the Low Limit less than 15°F (8°C)

below the High Limit results in improper

circulator function.

Fig. 5. Setpoints and differentials.

The L7124U can be in any of four operational states:

Normal, High-Limit, Low-Limit and Error. The controller

moves back and forth from High-Limit to Normal to

Low-Limit state as part of normal operation. However, the

controller enters only the Error state when there is an

abnormal condition such as an internal error or a bad

sensor. The operating states are:

1.

Normal: Boiler temperature has gone below the

high limit setting (minus the fixed differential) and

has not exceeded the high limit setting; or, the

boiler temperature has gone above the low limit

setting and has not gone below the low limit setting

(minus the fixed differential).

2.

High-Limit: Boiler temperature has gone above the

high limit setting and has not dropped below the

high limit setting (minus the fixed differential).

3.

Low-Limit: Boiler temperature has gone below the

low limit setting (minus the low limit differential) and

has not gone above the low limit setting.

4.

Error: The controller has detected an error

condition (e.g., open sensor) and has shut down

the burner output. The circulator and ZC output are

energized. The controller continues to function

and automatically restarts if the error condition

clears.

The operating sequence for the L7124U is shown in

Table 2.

CHECKOUT

Put the system into operation and observe operation

through at least one complete cycle to make sure that the

controller operates properly.

Table 2. L7124U Controller Operating Sequence.

LOW LIMIT

SETTING

HIGH LIMIT

SETTING

SWITCH BREAKS ON

TEMPERATURE RISE.

BURNER TURNS OFF.

CIRCULATOR OPERATES

ON A CALL FOR HEAT.

SWITCH MAKES ON

TEMPERATURE FALL.

BURNER OPERATES ON A

CALL FOR HEAT.

WITH NO HEATING

DEMAND, SWITCH BREAKS

ON TEMPERATURE RISE.

SWITCH MAKES ON

TEMPERATURE FALL,

BURNER IS ON TO

MAINTAIN MINIMUM

WATER TEMPERATURE.

CIRCULATOR IS OFF.

M21059

WHEN WATER REACHES LOW LIMIT SETTING, THE BURNER SHUTS

OFF OR THE CIRCULATOR PUMP STARTS (WHEN CALLING FOR HEAT).

1

1

Action

System Response

Thermostat

calls for

heat.

Circulator starts when water temperature is

above low limit setting (if applicable).

Boiler temperature is checked.

Burner starts when water temperature is

below high limit setting and above low limit

setting.

Boiler

exceeds the

high limit.

Burner is turned off. Burner restarts when

the water temperature drops below the

high limit setting minus the differential.

Thermostat

is satisfied.

Circulator and burner turn off.

Error

condition.

When an error condition is detected, all

outputs except C and ZC are shut down.

Burner is off. Control continues to function

and restarts when error is corrected.

During the error check sequence, the

system checks for drift in the sensor and

corrosion in the connections.

Summary of Contents for L7124U

Page 7: ...7 69 1232 2 ...