LKS 310 Actuator for air dampers on multi-stage and modulating burners

www.honeywell.com

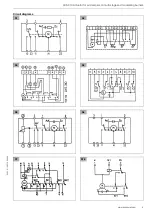

3

Technical data

Ordering information

LKS 310-15 A 5D - 30 S1

Circuit version

Drive time for 90°

3,5 s (3 Nm)

7 s (7 Nm)

10 s (10Nm)

15 s (15 Nm)

30 s (15 Nm)

Type of drive shaft

5A, 5B, 5C, 5D

see “Shaft versions”

Direction of rotation

A

clockwise

B

counter-clockwise

Model

Series

Standards and approvals

Conformity

Honeywell certifies herewith that the actuator LKS 310 complies

with the following regulations and standards:

• Standards of European Union 73/23 EWG and 93/68 EWG

• EN 60730-1 : 1991 A1 and A11 : 1991

• EN60730-2-5 : 1991

Accessories

Potentiometer-retrofit sets only on request.

Housing

robust aluminium housing with plastic

cover

Weight

approx. 1.8 kg

Drive motor

reversible synchronous motor

Clutch

red lever,

separates gearing from motor

Gearing

spur gearing, maintenance-free

Drive shaft

steel

PCBs

for all electrical functions, increased

conductor thickness wire cross-

section

Connection system

terminal blocks

Fitting and fastening

front of gear acts as contact area.

Fixing from outside via M5 or M6

screws, thread in housing

Switch point setting

stepless cam setting, lever-operated

or spindle-driven cams; if spindle-

driven, with superimposed scale

Position indicator

if desired the cover can contain a win-

dow and pointer, internally via a co-

running pointer and scale

Mains voltage

230 V -15% +10%

Mains frequency

50 Hz or 60 Hz

Safety class

I VDE 0631

Power consumption

7...15 VA

Duty cycle

Depending on motor, 50 to 70 %

in 2 minutes

Interference

suppression

N (according to VDE 0785)

Actuating angle

90°, in exceptional cases also larger

Mounting position

any

Protection

IP54, with appropriate design of the

cable entries, cover without window

(DIN 40050)

Cable entries

2 x PG11

Cable connection

terminal block for 0.5 mm

2

(min.) and

2.5 mm

2

(max.)

Direction of rotation

see “Type overview”

Torque and holding

torque

see “Type overview”

Drive times

3.5 ... 30 sec for 90°

Limit and auxiliary

switches

max. 7

operation with adjustable cam discs,

cams coloured in normal way:

blue

fully closed position

orange low load

red

high load

black

spare switches for

additional functions

switching voltage

AC 24 .... 230 V

switching capacity

with inductive loads 250 VA

Ambient temperature

operation 0....+60° C

transport and storage

-20....+60° C

CAUTION

Condensation, icing and exposure to water not

permitted

EN1C-011

4SZ20 R05

06