ML4105, ML4115, ML8105, ML8115 FAST-ACTING, TWO-POSITION ACTUATORS

63-2540—9

4

INSTALLATION

When Installing this Product...

1.

Read these instructions carefully. Failure to follow

them could damage the product or cause a hazardous

condition.

2.

Check the ratings given in the instructions and on the

product to make sure the product is suitable for your

application.

3.

Installer must be a trained, experienced service

technician.

4.

After installation is complete, check out product

operation as provided in these instructions.

IMPORTANT

All wiring must agree with applicable codes,

ordinances and regulations.

WARNING

Electrical Power Hazard.

Line voltage can cause death or serious injury

and short equipment circuitry.

Disconnect power supply before installation.

CAUTION

Electrical Shock or Equipment Damage Hazard.

Low voltage can shock individuals or short

equipment circuitry.

Disconnect power supply before installation.

Location and Mounting

The ML4105, ML4115, ML8105 and ML8115 DCA are

designed to open a damper by driving the damper shaft in

either clockwise

or counterclockwise

direction.

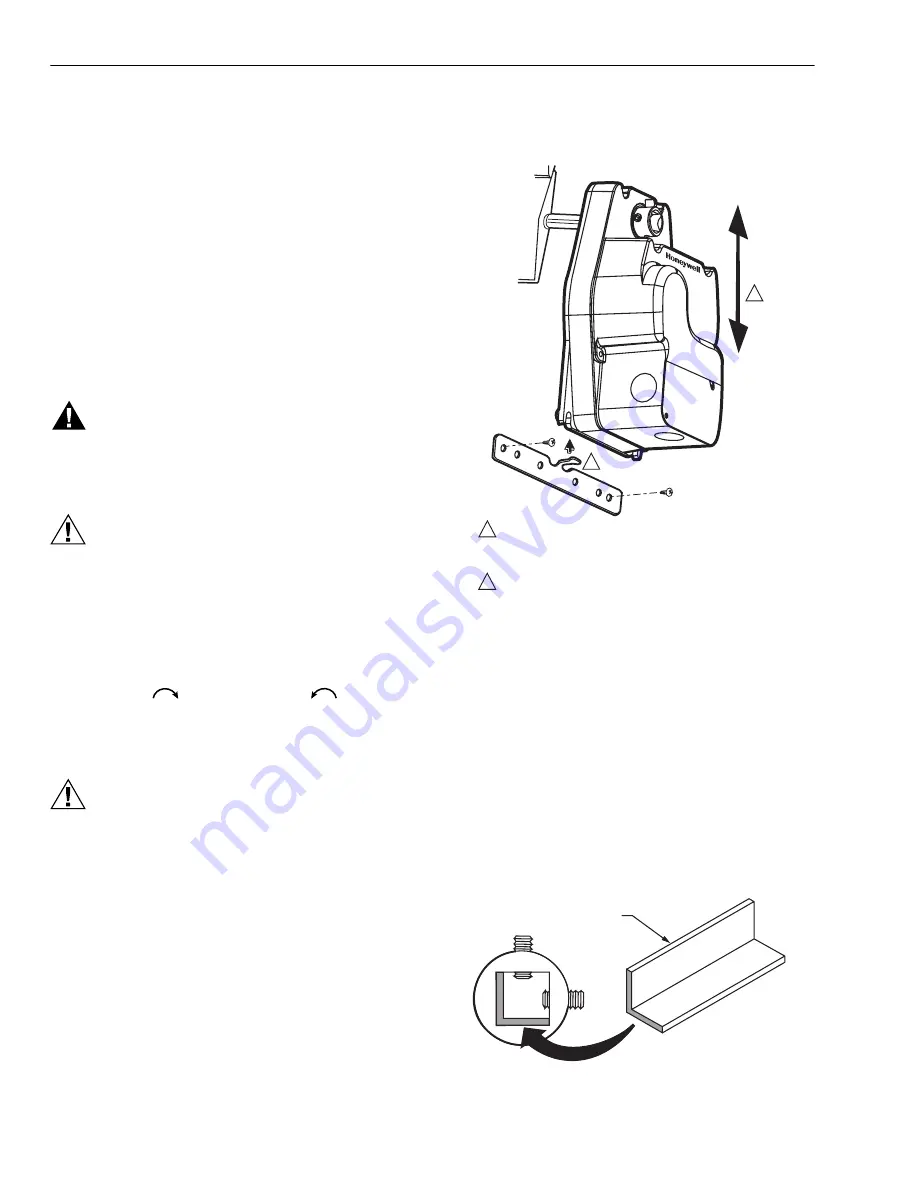

The actuator housing has two slots on the bottom that, with a

205649 Mounting Bracket, secure it flush to a damper box

(see Fig. 2). When mounted correctly, these slots allow the

actuator to

float

without rotating relative to the damper shaft.

CAUTION

Equipment Damage Hazard.

Tightly securing actuator to damper housing can

damage actuator.

Mount actuator to allow it to float along its vertical axis.

NOTE: ML4105, ML4115, ML8105, and ML8115 Actuators

are shipped in the fully closed position.

Fig. 2. Mounting actuator to damper housing.

Preparation

Before mounting the actuator onto the damper shaft,

determine the damper shaft size (3/8 in. to 1/2 in.

[10 mm to 13 mm]).

If damper shaft is 3/8 in. (10 mm) round or square, use part

number 201391 Shaft Adapter

(not supplied with actuator)

.

Place adapter opposite set screws (see Fig. 3).

NOTE: The damper shaft adapter centers a 3/8 in. (10 mm)

damper shaft in the hub. Failure to use adapter can

cause mounting screws to loosen. A 1/2 in. (13 mm)

damper shaft does not require an adapter.

Fig. 3. Using damper shaft adapter for

3/8 in. (10 mm) damper shafts.

M13054A

ENSURE THAT MOUNTING ASSEMBLY PREVENTS ACTUATOR

ROTATION AND ALLOWS ACTUATOR TO FLOAT ALONG

INDICATED AXIS. WHEN TOO TIGHT, THE RESULTING BINDING

CAN DAMAGE THE ACTUATOR OR REDUCE TORQUE OUTPUT.

ACCESSORY MOUNTING BRACKET IS NOT SUPPLIED WITH

THE ACTUATOR.

1

1

2

2

SH

A

FT

A

D

A

PTER

M2064