35 AND 70 LB-IN. NON-SPRING RETURN DIRECT COUPLED ACTUATORS

5

63-2209—8

INSTALLATION

When Installing this Product...

1.

Read these instructions carefully. Failure to follow them

could damage the product or cause a hazardous

condition.

2.

Check the ratings given in the instructions and on the

product to make sure the product is suitable for your

application.

3.

Installer must be a trained, experienced service

technician.

4.

After installation is complete, check out product

operation as provided in these instructions.

IMPORTANT

All wiring must agree with applicable codes,

ordinances and regulations.

WARNING

Explosion Hazard.

A spark from the actuator or attached accessories

can result in serious injury or death.

Install the actuator in areas free of escaping gas and

other explosive vapors.

CAUTION

Electrical Shock or Equipment Damage Hazard.

Can shock individuals or short equipment

circuitry.

Disconnect all power supplies before installation.

Actuators with auxiliary switches can have more than

one disconnect.

CAUTION

Actuator Damage Hazard.

Deteriorating vapors and acid fumes can damage

the actuator metal parts.

Install actuator in areas free of acid fumes and

deteriorating vapors.

Location

Choose a location for the actuator that allows enough

clearance for mounting accessories and for servicing.

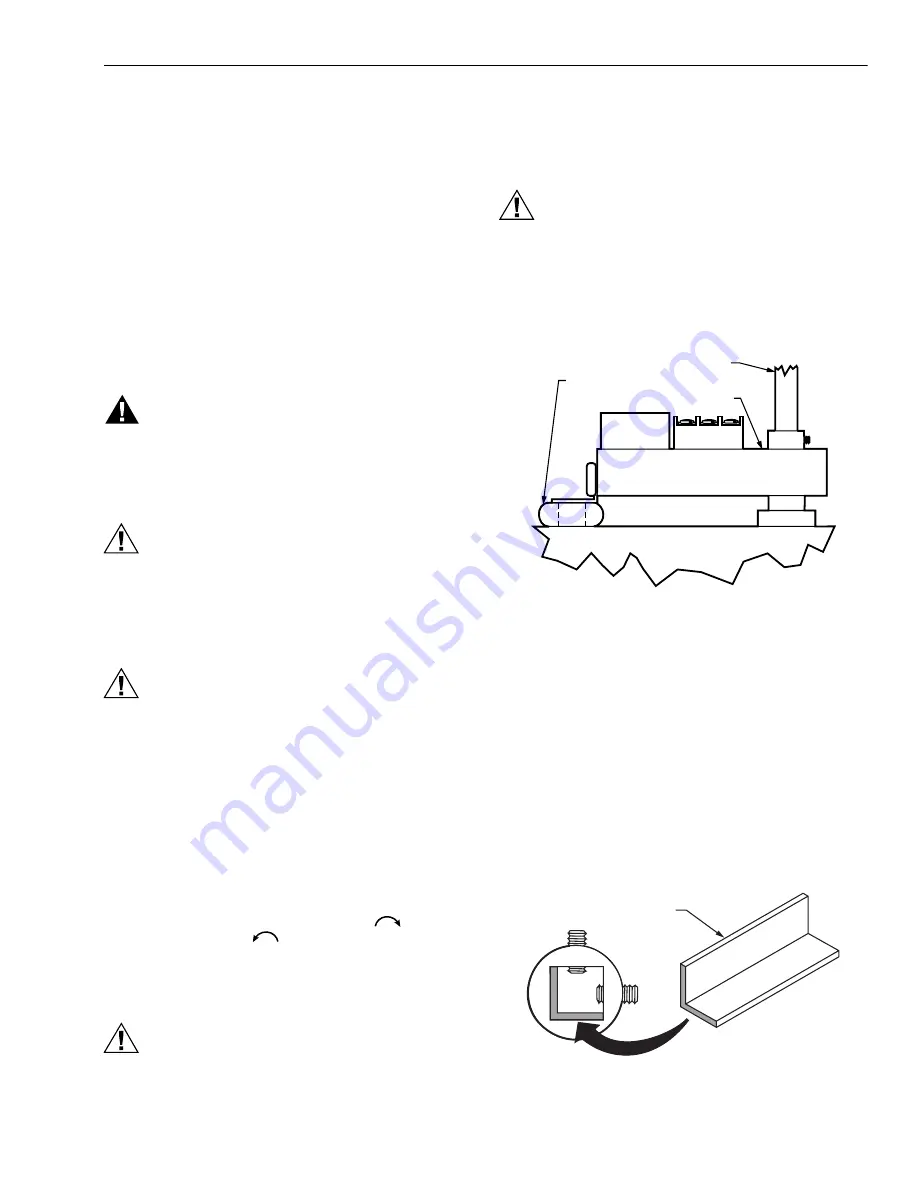

Mounting

These actuators are designed to open a damper or valve by

driving the shaft in either the clockwise (cw)

or

counterclockwise (ccw)

direction. The actuator has a

mounting tab on the bottom that secures it to a damper box

or valve linkage. When mounted correctly, this tab allows the

actuator to float without rotating relative to the shaft. The tab

is sized for 1/4 in. screw or pin (not included).

CAUTION

Equipment Damage Hazard.

Tightly securing mounting tab to damper housing

can damage actuator.

Once mounted, the actuator must be allowed to float;

do not fully tighten the screw.

These actuators are shipped in the fully clockwise 90° position

as viewed from the end of the damper shaft.

CAUTION

Equipment Damage Hazard.

Mounting actuator unevenly with damper housing

can damage actuator.

Mount actuator flush with damper housing or add

spacer between mounting tab and damper box

housing (see Fig. 2).

Fig. 2. Mounting actuator to VAV box when

actuator is not flush with box.

Preparation

Before mounting the actuator onto the shaft, determine the

following:

1.

Size of the shaft (3/8 in. to 1/2 in.).

2.

Direction the shaft rotates to open the device (cw or

ccw). See Fig. 4.

3.

Degrees of actuator stroke for opening device (45°, 60°,

or 90°).

If the shaft is 3/8 in. round or square, use part number 201391

Shaft Adapter provided inside the bag assembly shipped with

the actuator. Place the adapter opposite the setscrews (see

Fig. 3. Using shaft adapter for 3/8 in. shafts.

ADD SPACER BETWEEN

DAMPER BOX AND TAB

DAMPER

SHAFT

ML6161

ML6174

VAV BOX HOUSING

M11624A

SHAFT ADAPTER

M2064