11

63-2483—2

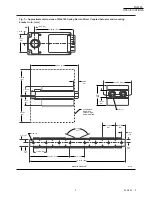

ML6185

CHECKOUT

Checkout

The ML6185 Direct Coupled Actuator can be checked

out either directly or by using a controller.

IMPORTANT: When power is interrupted, the actuator

returns to the normal starting position using the spring

mechanism. When power is restored, the controller

input will not operate the actuator until the spring is

fully wound and locked. The spring winding process

takes approximately 100 seconds, depending on the

number of degrees of spring return remaining at power

interrupt (i.e., 10

°

of spring return remaining takes 10

seconds). (If the actuator is not in the closed position,

it will run to the closed position as the spring is

winding.) Once the spring is locked in its fully wound

position, the actuator responds to inputs to the red-to-

blue or red-to-yellow leadwires.

DIRECT CHECKOUT

1. Mount the actuator for the required application (either

cw or ccw rotation to open the damper).

2. Check the damper position and make sure that 24 Vac is

present on the red and black leadwires.

3. Make sure the actuator spring is fully wound and

locked by applying power for at least 100 seconds.

4. Connect 24 Vac to the appropriate leadwires (red to

blue or red to yellow) to move the damper to the opposite

position. The ML6185 should drive the damper.

5. If the actuator does not run, verify that the actuator is

properly installed for either cw or ccw rotation.

6. If the actuator operates in the opposite direction than

desired, reverse the blue and yellow leadwires.

7. If the actuator is correctly installed and still does not

run, replace the actuator.

CONTROLLER CHECKOUT

1. Adjust the setpoint of the controller to call for cooling.

Observe the actuator.

2. If the damper is closed, it should begin to open.

3. If the damper remains closed, move the setpoint of the

controller farther below the room temperature.

4. If the damper still does not move, check for the

presence of 24 Vac in the input.

5. Make sure the actuator spring is fully wound by

applying power for at least 100 seconds.

6. If 24 Vac is present and the actuator does not operate,

reverse the controller leadwires to determine if the device

was miswired.

7. If the wiring is correct and 24 Vac is present on the input

terminals but the actuator does not run, replace the actuator.