9

63-2483—2

ML6185

INSTALLATION • OPERATION

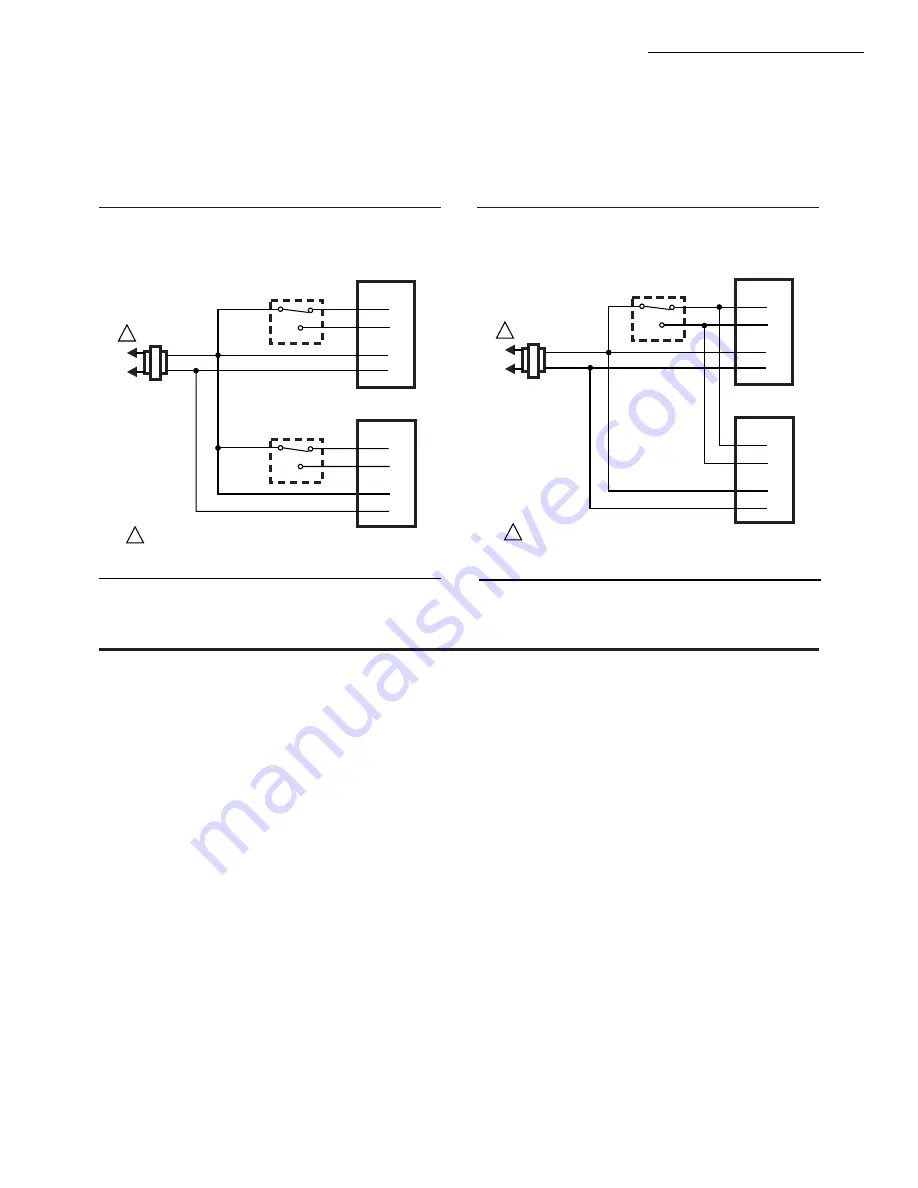

Connecting ML6185 Actuators in Parallel

ML6185 Actuators can be stacked on one damper shaft

to increase the output torque required to drive dampers

larger than 16 square feet.

To make sure proper phasing occurs, connect all four

leadwires (red, black, yellow and blue) in parallel. The

number of actuators that may be wired in parallel is depen-

dent on the transformer VA rating. Make certain that the

connected load does not exceed the current capacity of the

controller/thermostat. See Fig. 10 and 11.

Fig. 11—Common transformer with one

controller output and two actuators.

Fig. 10—Common transformer with two

controller outputs and two actuators.

four distinct positions where the indicator can be placed.

The indicator can be removed (by first removing the output

hub) to provide proper damper orientation. The indicator

can be indexed to show cw or ccw open or closed, using the

detents that are 90

°

apart. See Fig. 12. If the spring return

position is the open position, rotate the indicator until it

points to 90 on the scale. If the spring return position is the

closed position, rotate the indicator until it points to zero on

the scale. A detent can be felt at both stops; the detents

maintain the indicator position.

The ML6185D and ML6185F models provide a time-

out function that removes power from the actuator sub-

motor if the actuator remains in one position (closed, open

or any intermediate position) for longer than a nominal 100

seconds. This time-out function helps to extend actuator

life.

IMPORTANT: The ML6185 was designed to provide 7500

spring returns; therefore, the actuator can be unpowered

daily for night shutdown control. However, rapidly

cycling the actuator by removing control voltage will

lead to premature spring failure.

Operation

L1

(HOT)

L2

1

1

BLUE

YELLOW

RED

BLACK

ML6185

BLUE

YELLOW

RED

BLACK

ML6185

M7225A

POWER SUPPLY. PROVIDE DISCONNECT MEANS

AND OVERLOAD PROTECTION AS REQUIRED.

CONTROLLER

CONTROLLER

R

B

W

R

B

W

L1

(HOT)

L2

1

1

BLUE

YELLOW

RED

BLACK

ML6185

BLUE

YELLOW

RED

BLACK

ML6185

M7226A

POWER SUPPLY. PROVIDE DISCONNECT MEANS

AND OVERLOAD PROTECTION AS REQUIRED.

CONTROLLER

R

B

W

The ML6185 Direct Coupled Actuator is designed to be

used in ventilating and air conditioning installations to

operate dampers, ventilation flaps and louvers requiring up

to 50 lb-in. torque. If the power fails, the actuator will

spring return to the starting position. The actuator is de-

signed for reversible mounting. Arrows are molded into the

covers to show the spring return direction. The larger cover

shows a counterclockwise (ccw) spring rotation; the smaller

cover shows a clockwise (cw) spring rotation.

The ML6185 Direct Coupled Actuator is operated by an

spdt floating controller. When using an spdt floating con-

troller, the actuator will be driven toward its fully open

position when the controller makes R to B and toward the

fully closed position when the controller makes R to W. It

stops when neither contact is made.

IMPORTANT: The ML6185 is designed to respond to

instantaneous contact closures from a DDC Con-

troller. Be careful not to short cycle the actuator.

Unstable damper control may cause premature actua-

tor failure.

The actuator has a position indicator to depict shaft

position. As the indicator moves with the shaft, it gives an

angular representation of the damper position. There are