PRODUCT DATA

® U.S. Registered Trademark

© 2004 Honeywell International Inc.

All Rights Reserved

63-2511—1

ML6194, ML6294

Non-Spring Return

Direct Coupled Actuators

APPLICATION

The ML6194 and ML6294 Non-Spring Return Direct Coupled

Actuators (DCA) provide floating single-pole, double-throw

(spdt) control of dampers or valves in heating, ventilating, and

air conditioning (HVAC) applications. The ML6294 has an

internal, electrically isolated feedback potentiometer that can

be used to provide indication of motor output hub position or

slave a Series 90 actuator.

FEATURES

• Mount directly on 1/2 in. to 3/4 in. (13 to 19 mm) round

or square shaft. Mount on 1 in. (26 mm) round shafts

with appropriate insert. All models shipped with 1 in.

insert.

• 300 lb-in. (34 N•m) torque.

• Magnetic coupling eliminates need for mechanical

stops or limit switch adjustments by limiting stall

torque, which is dependent on temperature. Nominal

stall torque at room temperature of 68°F (20°C) is 410

lb-in.

• 95° stroke provides necessary compression of

rubber/neoprene gaskets commonly used on 90° low

leakage dampers.

• Declutch feature allows manual adjustment.

• 165 second synchronous timing can eliminate need for

feedback position indication in closed-loop

temperature control applications.

• Both single-point and three-point mounting

compatibility to allow installation flexibility.

• Models available with or without time-out feature.

Contents

Application ........................................................................

Features ...........................................................................

Specifications ...................................................................

Ordering Information ........................................................

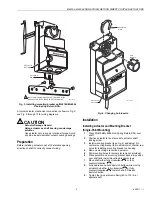

Installation ........................................................................

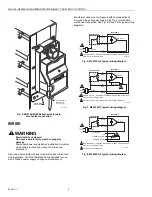

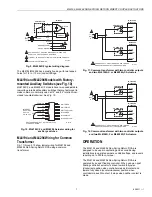

Wiring ...............................................................................

Operation ..........................................................................

Checkout ..........................................................................

Troubleshooting ................................................................