63-2511—1 G.R. Rev. 06-04

www.honeywell.com

Automation and Control Solutions

Honeywell International Inc.

Honeywell Limited-Honeywell Limitée

1985 Douglas Drive North

35 Dynamic Drive

Golden Valley, MN 55422

Scarborough, Ontario

M1V 4Z9

ML6194, ML6294 NON-SPRING RETURN DIRECT COUPLED ACTUATORS

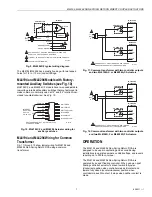

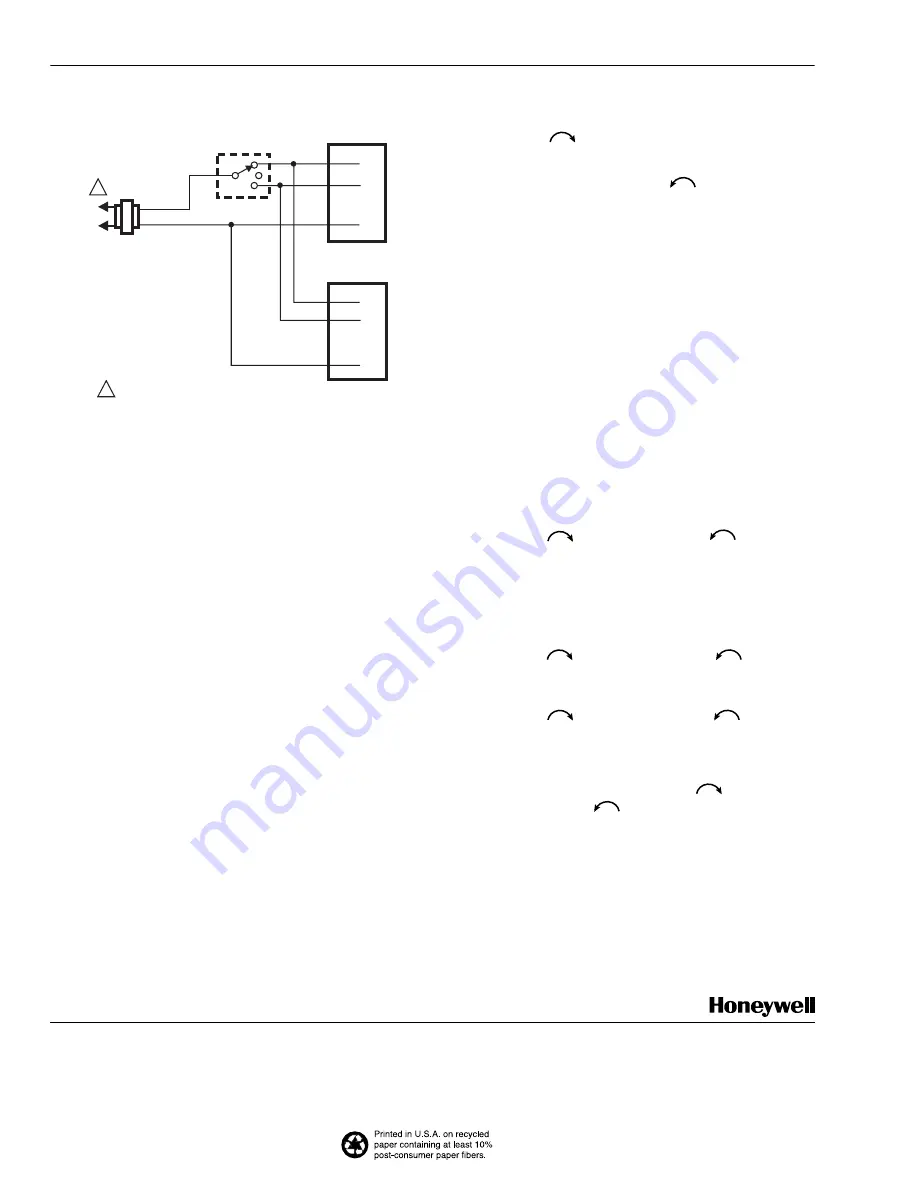

Fig. 13. Common transformer with one controller output

and two ML6194A,C or ML6294A,C Actuators.

IMPORTANT

ML6194/ML6294 Actuators can operate with a DDC

Controller that emulates an spdt break-before-make

switch. Do not short-cycle actuator. Short-cycling

actuator can cause premature failure.

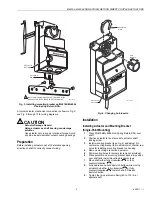

The actuator has a position indicator to show shaft position.

As the indicator moves with the shaft, it gives an angular

representation of shaft position. The indicator can be rotated

to show open or closed position.

ML6194D,F and ML6294D,F models provide a time-out

feature that removes power from actuator submotor if the

actuator receives the same signal or no call from controller for

longer than a nominal five minutes. This time-out feature

helps to extend actuator life.

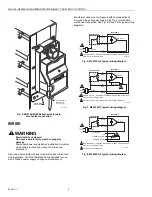

CHECKOUT

Use following procedure to check out ML6194 and ML6294

Non-Spring Return DCA:

1.

Check that actuator position indicator and shaft position

agree.

2.

If actuator has a time-out feature, apply 24 Vac to black

(T1) and red (T2) leads (see Fig. 7 or 9).

3.

Apply 24 Vac control signal to blue (B) lead with respect

to black (T1) lead. The actuator should drive shaft open

(clockwise

).

4.

Apply 24 Vac control signal to yellow (W) lead with

respect to black (T1) lead. The actuator should drive

shaft closed (counterclockwise

).

5.

If 24 Vac control signal is removed, actuator should

stop.

TROUBLESHOOTING

If actuator does not drive, travel full stroke, or operate properly

during checkout, perform following troubleshooting procedure

before replacing actuator:

1.

Check actuator label to make sure proper power and

control signal requirements are met.

2.

When actuator should be driving, check for 24 Vac at

actuator wires:

a. Black (T1) and yellow (W) or blue (B).

b. Black (T1) and red (T2).

3.

If voltage is not present or is low, check power supply

and controller.

4.

If actuator does not drive in correct direction when a

control signal is applied, reverse yellow and blue wires.

5.

Remove power and fully depress and hold down

disengage button while trying to turn shaft

clockwise

and counterclockwise

. If shaft

turns freely through 90° stroke, and actuator is installed

correctly, replace actuator.

6.

If shaft does not turn freely for full 90° stroke, check for

any binding and verify that actuator is loose on its

mounting bracket to prevent binding. If necessary,

adjust mounting bracket to prevent binding.

7.

If no binding is present, remove actuator and turn shaft

clockwise

and counterclockwise

. If shaft

does not turn freely, repair or replace damper.

8.

If shaft turns freely, fully depress and hold down

disengage button and turn actuator hub

clockwise

and counterclockwise

. If actuator

hub does not turn, replace actuator.

9.

If actuator and shaft turn freely, remount actuator

following instructions in Installation section. Make sure

actuator does not bind. Also, make sure that shaft and

actuator are at the same clockwise

or

counterclockwise

end stop when assembled.

Hook up wires and repeat checkout. If necessary,

troubleshoot again.

L1

(HOT)

L2

1

1

BLACK

BLACK

ML6194A,C

ML6294A,C

ML6194A,C

ML6294A,C

M11279A

POWER SUPPLY. PROVIDE DISCONNECT MEANS

AND OVERLOAD PROTECTION AS REQUIRED.

CONTROLLER

BLUE

YELLOW

BLUE

YELLOW