ML6194, ML6294 NON-SPRING RETURN DIRECT COUPLED ACTUATORS

63-2511—1

6

Fig. 5. ML6194/ML6294 Actuator standard

mechanical connection.

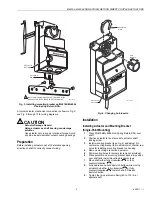

WIRING

WARNING

Electrical Shock Hazard.

Can cause severe injury, death or property

damage.

Disconnect power supply before installation. Actuators

with auxiliary switches can have more than one

disconnect.

All wiring must comply with local electrical codes, ordinances

and regulations. The ML6194/ML6294 are designed for use

with a Class 2 power supply. Voltage and frequency of

transformer used must correspond with characteristics of

motor and those of power supply. See Fig. 5 for standard

mechanical connection. See Fig. 6 through 9 for typical wiring

diagrams.

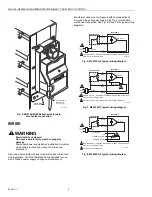

Fig. 6. ML6194A,C typical wiring diagram.

Fig. 7. ML6194D,F typical wiring diagram.

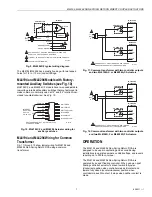

Fig. 8. ML6294A,C typical wiring diagram.

M11273A

MOUNTING

BRACKET

TO JUNCTION

BOX (UP TO

3 FT AWAY)

30

30

0

60

60

90

L1

(HOT)

L2

1

1

MOTOR

24 VAC

B

BLUE

W

YELLOW

T2

BLACK

ML6194A,C

M11283A

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED.

CONTROLLER

L1

(HOT)

L2

1

1

2

2

MOTOR

TIME OUT

24 VAC

B

BLUE

W

YELLOW

T2

RED

T1

BLACK

ML6194D,F

M11282A

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED.

TIME-OUT FUNCTION AVAILABLE WITH ML6194D,F MODELS.

CONTROLLER

L1

(HOT)

L2

1

1

2

2

MOTOR

24 VAC

B

BLUE

W

YELLOW

T1 BLACK

ML6294A,C

M11281A

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED.

500 OHM POTENTIOMETER.

ORANGE (OPEN)

TAN

GREEN (CLOSED)

CONTROLLER