ML6421, ML7421 NON-SPRING RETURN ELECTRIC LINEAR VALVE ACTUATORS

7

63-2515—4

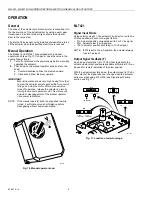

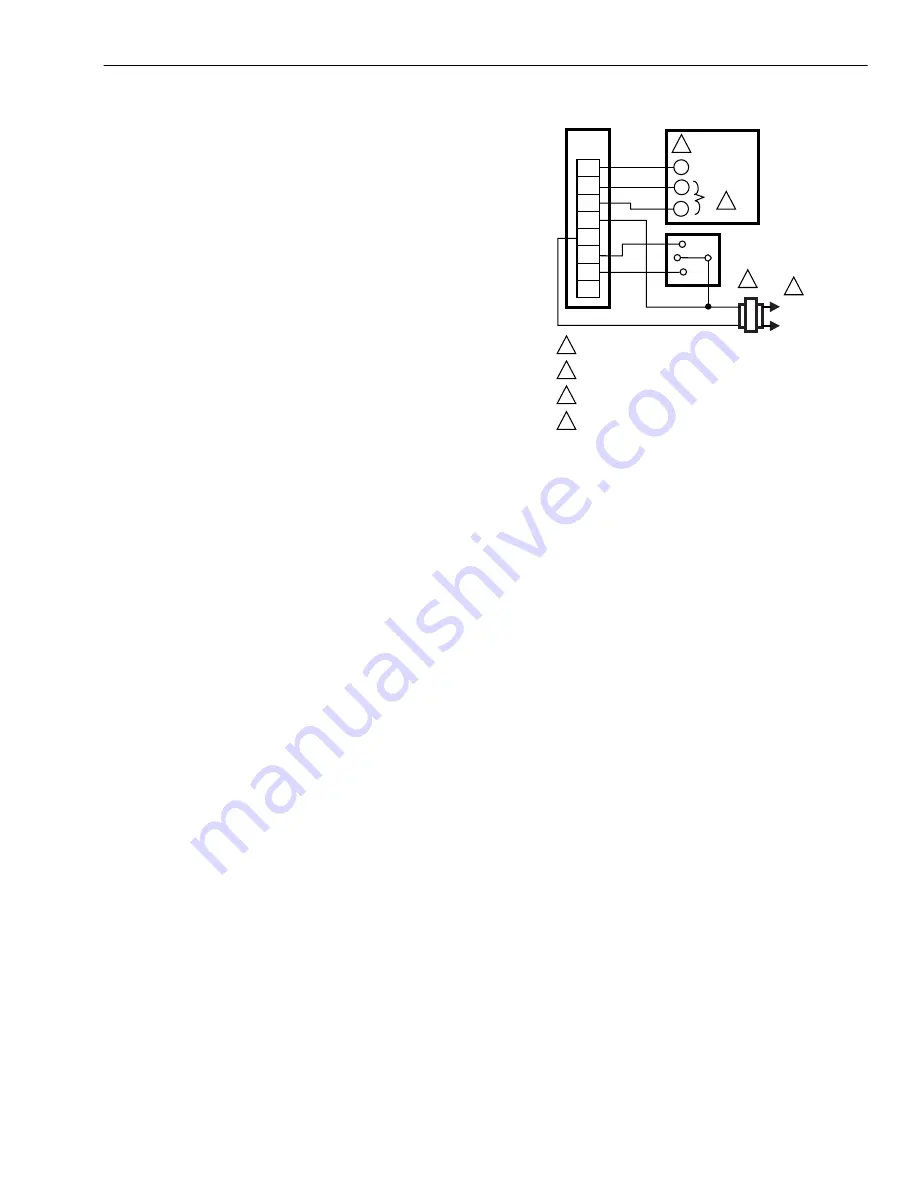

Actuator Override

To override the control signal (for freeze protection or similar

applications), connect the 24 Vac common (T2) to either

terminal O1 or O2. Connecting to terminal O1 fully extends

the actuator stem. Connecting to O2 fully retracts the actuator

stem.

The control signal (+) is ignored when the override signal is

applied to terminal O1 or O2. This override can be achieved

with a switch or a relay. See Fig. 12.

Direction of Action

The direction of action can be changed by repositioning the

selector plug W3.

Fig. 12. Connections for overriding control signal to drive

actuator to a specific position.

CHECKOUT

The actuator can be checked out either directly or using a controller.

Direct Checkout

1.

Mount the actuator for the required application.

2.

Check the valve position and make sure that 24 Vac is

correctly applied to the actuator.

3.

Apply the control signal to the appropriate leadwires to

move the valve in the required direction.

4.

If the actuator does not move, make sure the actuator is

properly installed.

5.

If the actuator is correctly installed and does not run,

replace the actuator.

Controller Checkout

1.

Adjust the setpoint of the controller to call for opening or

closing the valve. Observe the actuator.

2.

If the valve is closed, it should begin to open.

3.

If the valve remains closed, move the setpoint further

toward the open setting.

4.

If the valve does not move, check for 24 Vac in the

actuator power input.

5.

If 24 Vac is present and the actuator does not operate,

reverse the controller leadwires to determine if the

device is incorrectly wired.

6.

If wiring is correct, 24 Vac is present on the power input

terminals, and the actuator does not run, replace the

actuator.

POWER SUPPLY. PROVIDE DISCONNECT MEANS

AND OVERLOAD PROTECTION AS REQUIRED.

F

+

0-10Vdc OR 2-10 Vdc CONTROL SIGNAL. SEE SIGNAL

INPUT (+) SECTION.

SEE OVERRIDE SECTION FOR DETAILS ON

OVERRIDE OPERATION.

2-10 Vdc FEEDBACK SIGNAL. SEE OUTPUT SIGNAL

FEEDBACK SECTION.

ML7421

WIRING

STRIP

F

+

–

T2

T1

O1

O2

1

3

4

2

INPUT

(FEEDBACK)

OUTPUT

3

2

SP3T

OVERRIDE

SWITCH

4

1

L1

(HOT)

L2

–

M17438