ML6425, ML7425 SPRING RETURN ELECTRIC LINEAR VALVE ACTUATORS

63-2516—04

6

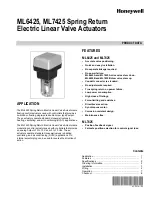

Fig. 11. ML7425 Wiring using 2 to 10 Vdc Control Signal

and a Common Transformer.

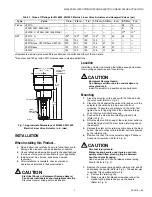

Fig. 12. ML7425 Wiring using 4 to 20 mA Control Signal

and Separate Transformers.

NOTE: 500 ohm resistor not shipped with product.

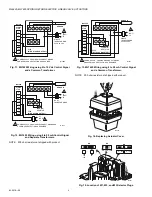

Fig. 13. ML7425 Wiring using 4 to 20 mA Control Signal

and a Common Transformer.

NOTE: 500 ohm resistor not shipped with product.

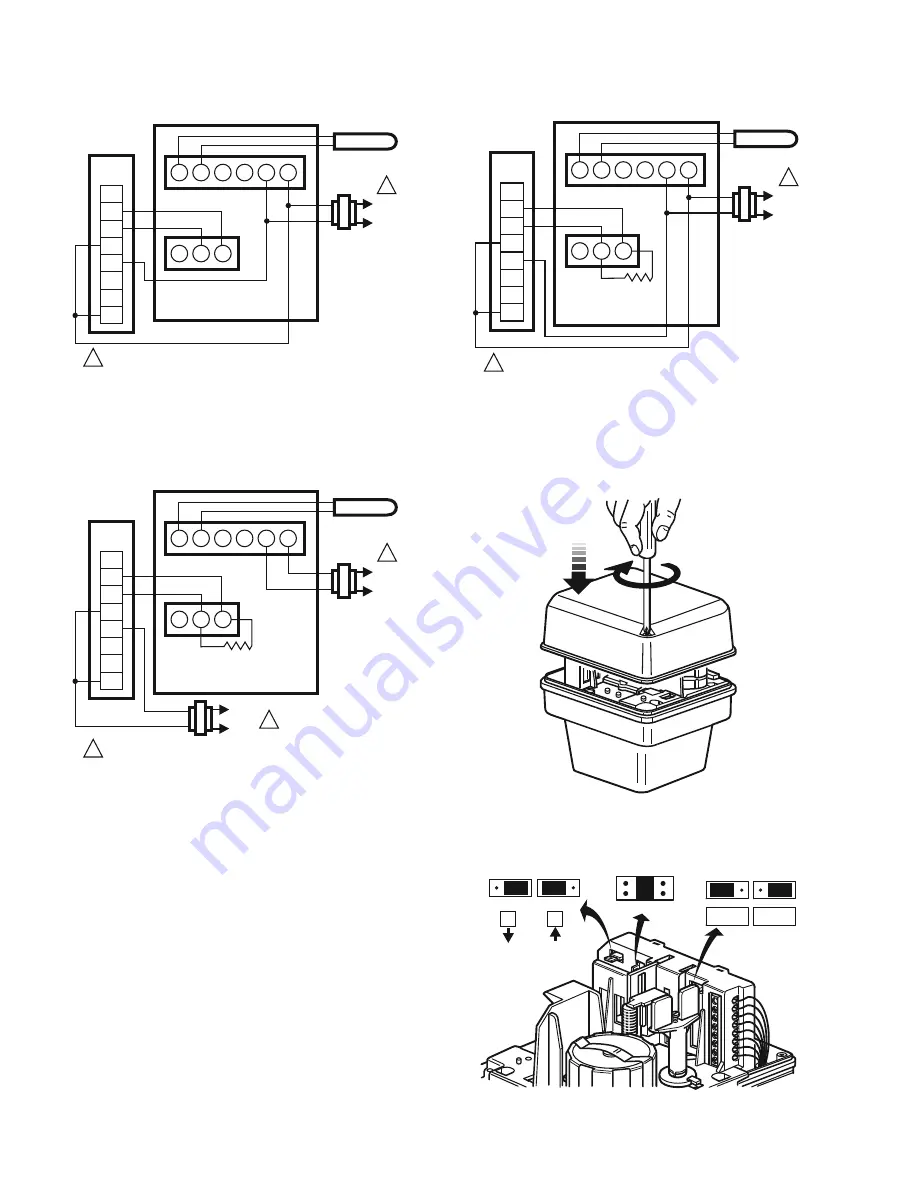

Fig. 14. Replacing Actuator Cover.

Fig. 15. Location of W1, W2, and W3 Selector Plugs.

L1

(HOT)

L2

1

1

WIRING

STRIP

F

+

–

T2

T1

O1

O2

TS

1

1

2

2

3

3

4

5

6

ML7425

T775

(WITH 2-10 VDC OUTPUT)

SINGLE

TRANSFORMER

40 VA 24 VAC

POWER SUPPLY. PROVIDE DISCONNECT MEANS

AND OVERLOAD PROTECTION AS REQUIRED.

M7895

SENSOR

L1

(HOT)

L2

1

1

WIRING

STRIP

F

+

–

T2

T1

O1

O2

TS

1

1

2

2

3

3

4

5

6

L1

(HOT)

L2

1

ML7425

T775

(WITH 4-20 MA OUTPUT)

DUAL

TRANSFORMERS

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

M7896

500 OHM

RESISTOR

SENSOR

L1

(HOT)

L2

1

1

WIRING

STRIP

F

+

–

T2

T1

O1

O2

TS

1

1

2

2

3

3

4

5

6

ML7425

SENSOR

T775

(WITH 4-20 MA OUTPUT)

SINGLE

TRANSFORMER

40 VA 24 VAC

POWER SUPPLY. PROVIDE DISCONNECT MEANS

AND OVERLOAD PROTECTION AS REQUIRED.

M7897

500 OHM

RESISTOR

M6628

M6631

0 ... 10V

2 ... 10V

W2

10V

0%

10V

W3

W1

100%

50%