ML6425, ML7425 SPRING RETURN ELECTRIC LINEAR VALVE ACTUATORS

3

63-2516—04

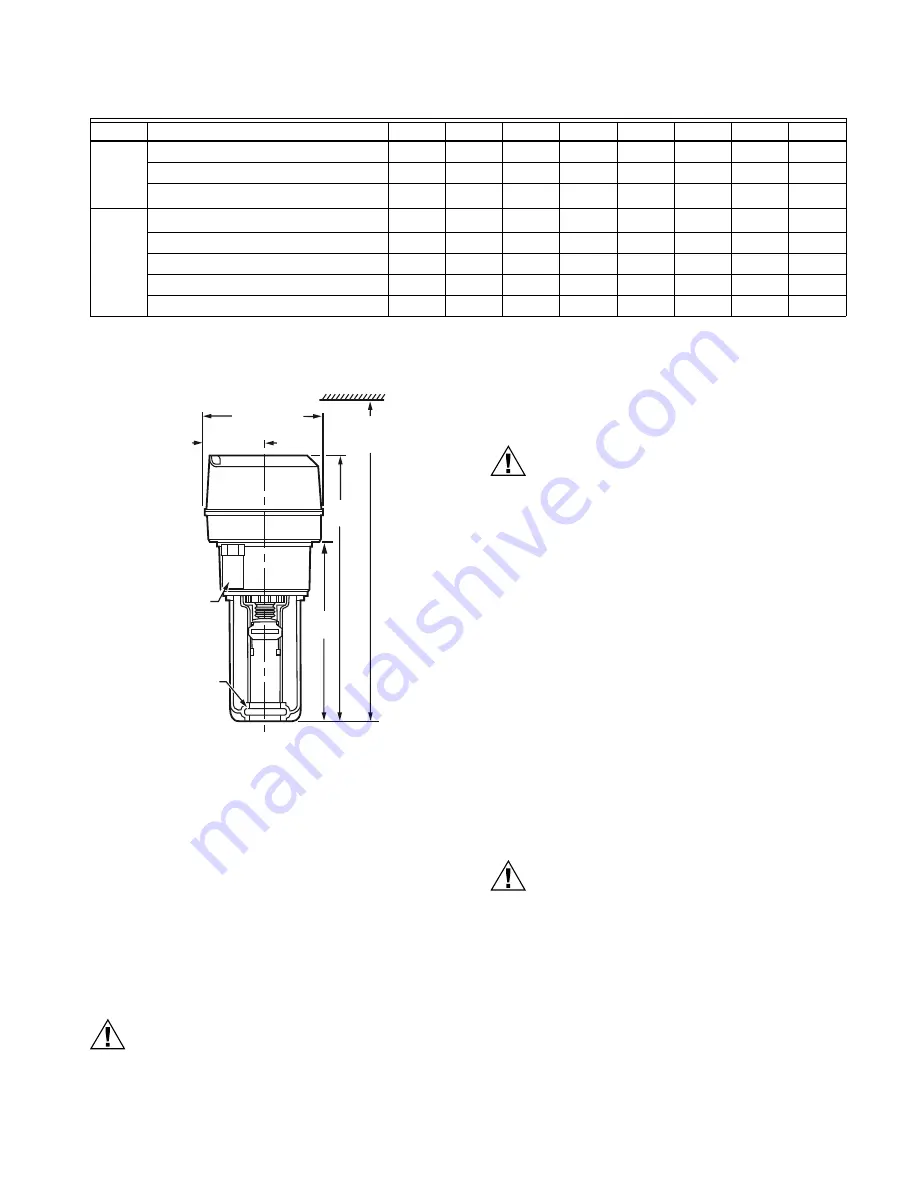

Table 1. Close-off Ratings for ML6425, ML7425 Electric Linear Valve Actuators and Honeywell Valves (psi).

a

Represents maximum pressure difference between the outlet and either of the two inlets.

b

Do not exceed 100 psi with V5011G valves used in steam applications.

Fig. 1. Approximate Dimensions of ML6425, ML7425

Electric Linear Valve Actuator in in. (mm).

INSTALLATION

When Installing this Product...

1.

Read instructions carefully. Failure to follow them could

damage the product or cause a hazardous condition.

2.

Check ratings and description given in the specifications

to make sure the product is suitable for your application.

3.

Installer must be a trained, experienced service

technician.

4.

After installation is complete, check out product

operation as provided in these instructions.

CAUTION

Electrical Shock or Equipment Damage Hazard.

Can shock individuals or short equipment circuitry.

Disconnect power supply before installation.

Location

Install the actuator in a location that allows enough clearance

for mounting accessories and for servicing.

CAUTION

Equipment Damage Hazard.

Can damage actuator due to condensation or a

valve gland leak.

Install the actuator in a position above horizontal.

Mounting

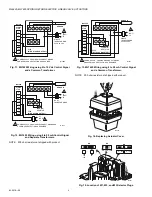

1.

Place the actuator on the valve with the U-bolt around

the valve collar (Refer to Fig. 2).

2.

Place the U-bolt against the valve collar and secure the

actuator to the valve by turning each U-bolt nut

clockwise. To assure even pressure on the collar, first

tighten the nuts finger-tight and then alternate turning

each U-bolt nut until both are snug.

3.

Push aside the stem button retaining clip and hold

(Refer to Fig. 3).

4.

Lift valve stem until the head of the valve stem button is

inside the large slot of the stem button retaining clip on

the actuator.

5.

Release the stem button retaining clip to secure the stem

button. Check to make certain the stem button is secured

by the retaining clip.

6.

Remove the cover from the actuator using a Phillips or

crosspoint screwdriver (Refer to Fig. 4).

CAUTION

Personal Injury Hazard.

Manual spring handle under tension can turn

quickly when lifted, pinching fingers between

handle and plastic casing.

Use a screwdriver to lift and release manual spring

handle (Refer to Fig. 5).

7.

Remove the manual spring handle retaining clip, and lift

and release the handle (Refer to Fig. 5). The easiest way

to perform this operation safely is to:

a. Remove the retaining clip.

b. Wedge a small, flat-bladed screwdriver under the

manual spring handle and pry up the handle

(Refer to Fig. 5).

Type

Valve

1/2 in.

3/4 in.

1 in.

1-1/4 in. 1-1/2 in.

2 in.

2-1/2 in.

3 in.

Flange

V5011A

—

—

—

—

—

—

28

16

V3350/ 3351/ 3450/ 3451

—

—

—

—

—

—

21

14

V5013B, C; V3360/ 3361/ 3460/ 3461

—

—

—

—

—

—

21

a

14

a

NPT

V5011F, G

150

b

150

b

150

b

134

b

77

49

28

16

V5011H, J

150

150

150

145

—

—

—

—

V5011N1xxx, V5011N3xxx, V5013N

230

230

163

104

67

37

—

—

V5011N2xxx

100

100

100

100

67

37

—

—

V5013F

150

150

150

126

77

49

—

—

5-5/15

(135)

6-5/16

(161)

x

2-11/16 (67)

14-5/16 (364)

MINIMUM

CLEARANCE

11-1/4

(284)

7-5/8

(192)

M7892A

1/2 (13) FPT

YOKE

DIAMETER

1-3/8 (35)