ML6874

INSTALLATION

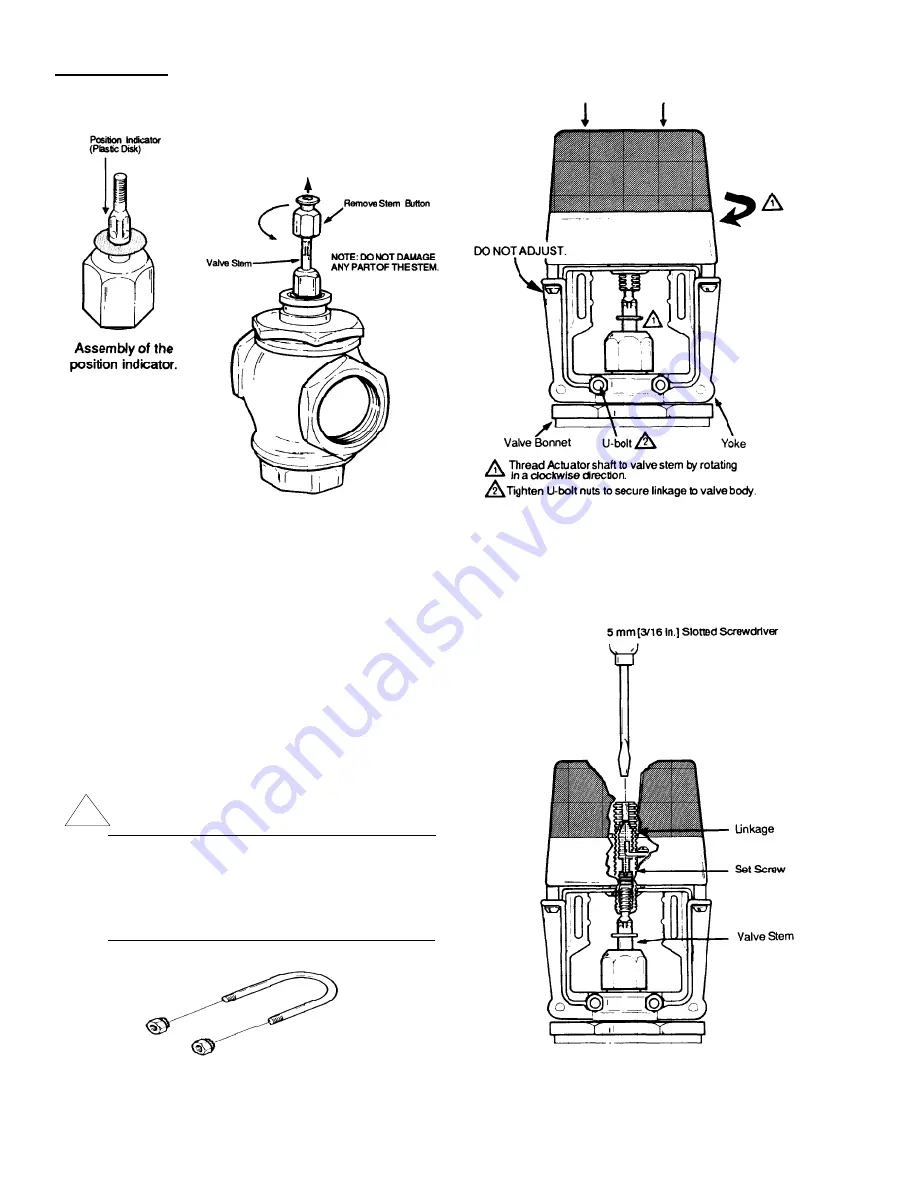

FIG.3 -- PREPARATION FOR VALVE ASSEMBLY.

5. Remove the plastic cover from the ML6874 by loosening the

two screws located on the top (Note: These screws are captive.

Rotate three complete revolutions to remove cover ). Drop

either Slot Headed or Allen Hex type of set screw (both are

included in the plastic bag ) into the top of the shaft, slotted/

Hexed side up. Or use the set screw from the valve stem

button.

6. Depending on which type of set screw was used, with a 5 mm

(3/16") Slotted screwdriver or 1/8"x 6" Allen wrench (included

in the plastic bag), tighten the set screw to lock valve stem in

place (Fig. 6).

!

WARNING

g

FIG. 5 -- U-BOLT ASSEMBLY.

4

FIG. 4 -- ASSEMBLY OF ML6874A TO VALVE.

OR

Allen Wrench

FIG. 6. -- LOCKING ML6874A DRIVE SHAFT TO

VALVE STEM