ML7295 SPRING RETURN DIRECT COUPLED ACTUATORS

63-2539—1

7

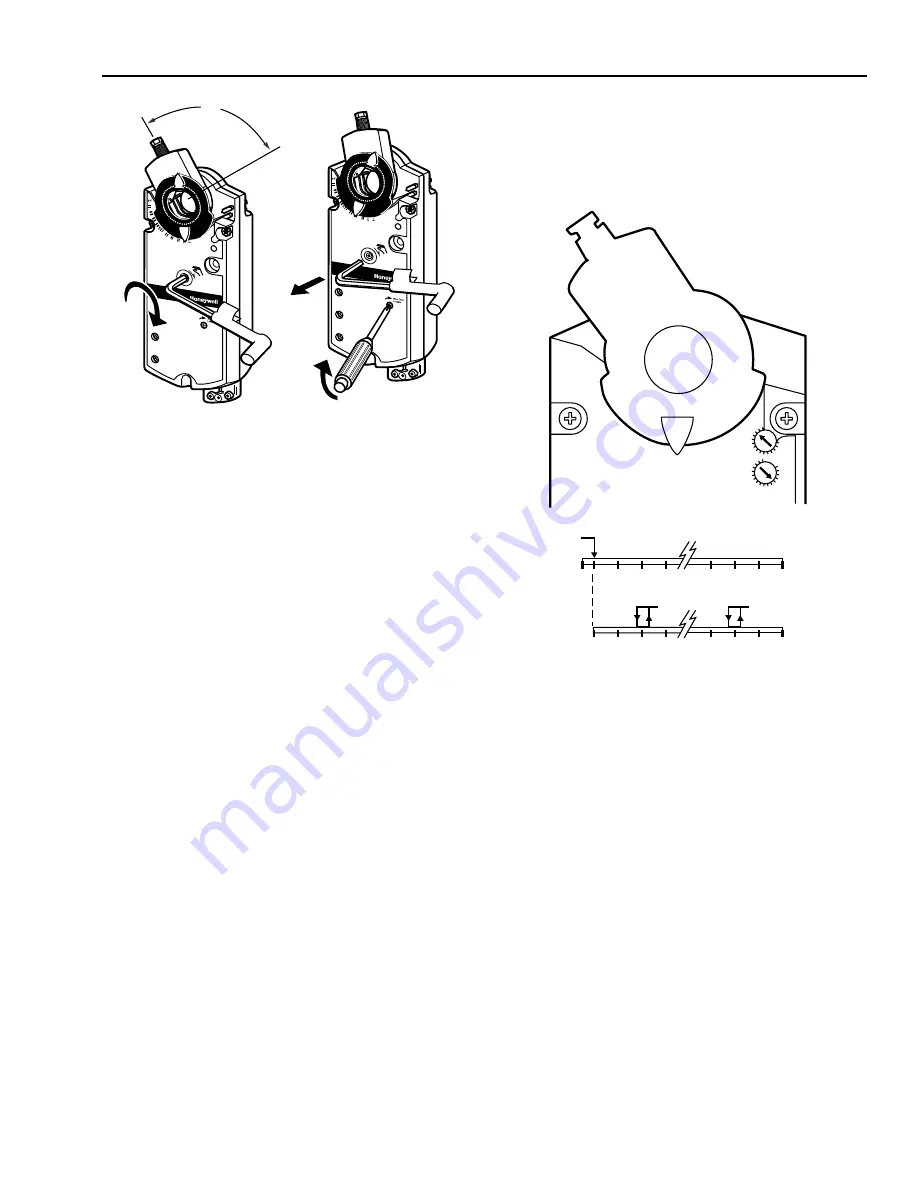

Fig. 8. Manual override of ML7295 Spring

Return Direct Coupled Actuators.

Auxiliary Switches (ML7295C,H only)

The ML7295C,H models have line voltage, fully adjustable

auxiliary switches. The switch setting interval (or differential)

is 5

°

.

The switches are set as follows:

1. If the power is on, turn it off; the actuator will spring

return to the 0

°

position.

IMPORTANT

If the shaft coupling has been adjusted according to

the Range Stop Adjustment instructions, the position

indicator must also be adjusted to indicate 0 at the

fail-safe position. If this is not done, the position

indicator will not correspond to the auxiliary switch

adjustment settings, as shown on the label.

2. Use a flat blade screwdriver to turn the switch

adjustment dials to the desired settings.

NOTE:

The numerical indication on the dials corresonds to

the location of the shaft coupling at which a signal

will be given by the switch (see Fig. 9).

Once power is restored, the actuator will return to normal

automated control.

20

30

30

10

20

40

40

50 60

70

70

80

90

A

B

AUX

SWITCH

ADD

0

°

-5

°

10

°

20

°

30

°

60

°

70

°

80

°

90

°

0

°

10

°

20

°

30

°

60

°

70

°

80

°

90

°

M11699

Fig. 9. Actuator rotary range and auxiliiary switch

signal locations.

CHECKOUT

To perform a checkout of the ML7295 DCA, proceed as

follows:

1. Check the damper or valve position and make sure that

24 Vac is present on the red and black leadwires.

2. Apply the control signal to the appropriate leadwires to

move the damper or valve away from the fail-safe

position. The ML7295 should drive the damper or valve.

3. If the actuator does not run, remove power and

manually operate the actuator, see Manual Override

section. If the shaft coupling moves, rotate it reaches

the mechanical stop. Turn the lock pin 1/4 turn to lock

the actuator in place. Reapply power and apply the

control signal to the appropriate leadwires to drive the

actuator in a cw direction.

4. If the actuator is correctly installed and still does not

run, replace the actuator.

M12447A

ROTATING

LOCKING IN PLACE

95

°

"CLICK"