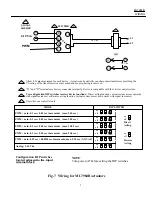

ML7984B

WIRING

4

24 Vac

1

2

ML7984B

L1

L2

T5

T6

R

W

C

3

SIGNAL

SOURCE

B

+

2-10 Vdc

PWM

OR

+

T6

28 Vdc

-

T5

1

3

2

4

Allow 0.5 amps maximum for each device. Actuators and controller can share same transformer providing the

VA rating of the transformer is not exceeded and proper phasing is observed.

"T5" and "W" terminals are factory connected internally. Device is compatible with the 3-wire control system.

Use configuration DIP switches to select device functions: Direct acting function ( actuator stem moves upwards

with signal increases ) or Reverse acting function ( actuator stem moves downwards with signal increases ).

Use either one controller only

1

2

3

on

off

4

on

off

Reverse

Acting

4

on

off

Direct

Acting

MODE

DIP SWITCH

PWM: min. 0.1 sec + 0.01 sec increments (max. 2.65 sec )

PWM: min. 0.1 sec + 0.02 sec increments (max. 5.20 sec )

PWM: min. 0.1 sec + 0.05 sec increments (max. 12.85 sec )

PWM: min. 0.1 sec + 0.10 sec increments (max. 25.6 sec )

PWM: min. 0.59 sec + 0.00918 sec increments (max. 2.93 sec ) NOVAR

Analog: 2-10 Vdc

1

2

3

on

off

1

2

3

on

off

1

2

3

on

off

1

2

3

on

off

1

2

3

on

off

Configuration DIP switches

NOTE:

located adjacent to the input

Turn power off before setting the DIP switches.

terminal block

Fig. 7 Wiring for ML7984B actuators

5