ML7984B

OPERATION AND CHECKOUT

Operation and checkout

Operation:

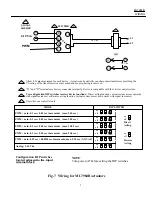

The recommended valve actuator power source is a class 2,

24V transformer or 28Vdc across terminals T5 &T6 (See

Fig.7). The internal circuitry provides dc power for the

electronic sensing and drive motor circuits. The sensing

circuits respond to the signal across the input terminals

based on the configuration DIP switches setting.

At the end of the valve stroke, the actuator continues to

drive and gradually develops the necessary force for

positive valve close-off.

automatically when the

predetermined current & for

The

motor

ce level

actuator

current

.

motor

reaches

stops

the

PWM mode:

The ML7984B is controlled by an intermittent voltage pulse

whose width varies in proportion to the desired actuator

position. This called pulse width modulation (PWM). The

PWM signal has two parts: a fixed pulse of a set width to

indicate a signal presence (e.g. 0.1 s) and a varible width

portion incremented in proportional to the signal percentage.

There are 255 increments available (e.g. 0.01 s). Thus, the

pulse width will be the minimum width plus the number of

increments times the incremental value (e.g. stroke mid

position is: 0.1s +128 x 0.01s = 1.38 s). The ML7984B

supports 5 different PMW timebased modes.

2-10 Vdc mode:

Control signal between signal input terminals is compared

to similar voltage across the actuator feedback

potentiometer. When these voltages are equal, the drive

motor and drive shaft are stationary.

As long as the value of controlled medium remains at the

controller setpoint, the circuit is in balance, and the actuator

does not run. When the value of the controlled medium

changes, the controller output voltage is changed causing

reference voltages in the circuit to be out of balance. As the

actuator moves in the direction to correct the medium

change, the feedback potentiometer also moves to rebalance

the circuit, and stop the actuator.

GENERAL NOTE:

1. For correct valve operation, the ML7984 must be field

configured with the DIP switches which are located beside

the terminal block, see wiring diagram for details. Turn

power off before setting the DIP switches .

2. There is a short delay in actuator response upon every

signal change. It is to screen any unwanted incoming signals.

3. For proper operation, voltage on the T5 & T6 must not

be less than 22Vac or 24Vdc during running or force

generating stages.

!

CAUTION:

1. Disconnect power supply before beginning installation to

prevent electrical shock and equipment damage.

2. All wiring must comply with applicable local electrical

codes, ordinances and regulations.

3. Make certain that the voltage and frequency of the power

supply correspond to the rating of the device.

4. DO NOT electrically operate the ML7984 before

assembly to the valve because damage not apparent to the

installer may occur.

Checkout:

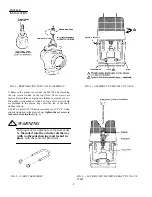

1. Make sure the valve stem is completely screwed into the

actuator drive shaft with no threads showing.

2. Make sure the valve stem is locked in place with the set

screw.

3. Make sure the Configuration DIP switches are set

correctly.

4. With 24Vac or 28Vdc power source connected to T5 &

T6, actuator operation can be verified by connecting

appropriate control signal (PWM or 2-10Vdc) from

controller to the signal input terminals (Fig. 7).

For direct acting: A modulating action can be obtained

simply by increasing the control signal width or level. The

actuator will travel from a fully closed position (Stem down)

to a fully open position ( Stem up ). For 2-10Vdc mode,

actuator defaults to closed position on signal failure.

For reverse acting: Decreasing controller signal width or

level will drive actuator from fully closed (Stem down) to a

fully open position (Stem up). For 2-10Vdc mode, actuator

defaults to open position on signal failure.

5. Operate the system (valve, actuator and controller) for

several cycles to ensure proper installation.

6. When checkout is completed, return the controller to the

desired setting.

NOTE: Device will ignore any input changes until it has

completed its repositioning relative to the initial signal input.

Home and Building Control

Honeywell

Limited/Limitée

Home and Building Control

Honeywell Inc.

Helping You Control Your World

155 Gordon Baker Road

1985 Douglas Drive North

North York, Ontario

Golden Valley, Minnesota 55422

Canada M2H 3N7

www.honeywell.com/building/components