ML7999A UNIVERSAL PARALLEL-POSITIONING ACTUATOR

5

65-0239—2

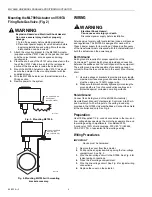

Fig. 5. Opening ML7999 low-voltage wiring compartment.

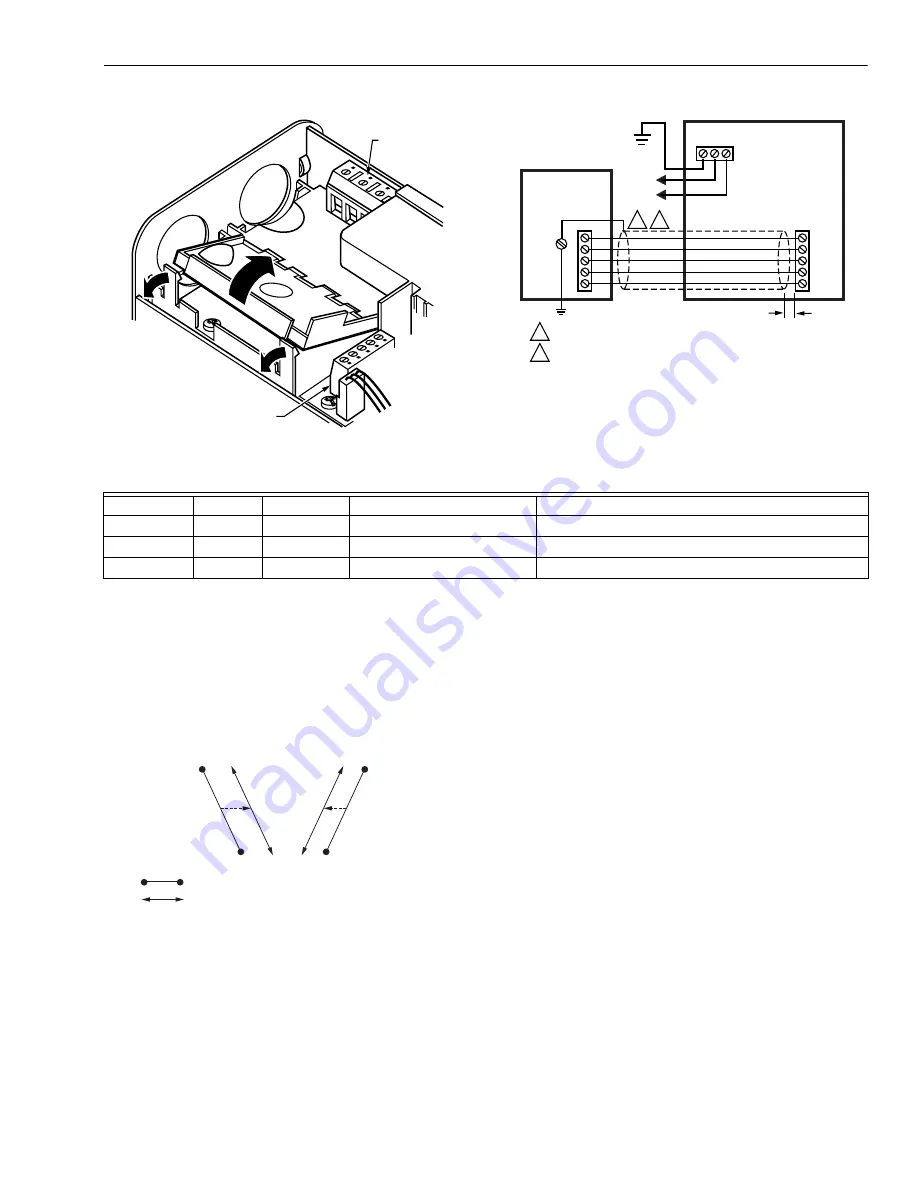

Fig. 6. Typical ML7999 wiring.

OPERATION

Table 1. On-Board LED Indications.

Actuator Setup

After the password (ID signal) has been written to the

ML7999, the actuator stroke will have to be determined for the

fuel, air and FGR, if used. The auto seek open/closed function

can be used to find the actuator end strokes. It is important, if

you use the auto seek open/closed function, that you move off

the mechanical end stops of the actuator by a

minimum of

five degrees

. See Fig. 7.

Fig. 7. Mechanical end stop changes for auto seek open/

closed function.

CHECKOUT AND TROUBLESHOOTING

Checkout

Refer to the R7999 literature (form 66-1120) for system

checkout.

Troubleshooting

If the actuator does not operate properly during Checkout,

perform the following troubleshooting steps. Perform these

steps before replacing the actuator:

1.

Check the actuator label to make sure the power and

control signal requirements are correct for the

application.

2.

Check for the presence of 120-240 Vac at the actuator

(L1) and (L2) connections when the actuator should be

driving. If the voltage is not present or is low, check the

power supply.

3.

Ensure actuator stroke matches stroke of damper or

valve.

a. Remove the cover.

b. Press the button labeled CW. The actuator should

drive the device clockwise.

c. Press the button labeled CCW. The actuator should

drive the device counterclockwise.

4.

If the actuator operates properly, check the controller for

proper output signals.

5.

If the actuator does not drive, remove power, disconnect

the actuator hub, and try to turn the shaft clockwise and

counterclockwise. If the shaft turns freely throughout the

90-degree stroke and the actuator is installed properly,

replace the actuator.

6.

If the shaft does not turn freely for the full 90 degrees,

check for binding. If necessary, adjust mounting to

prevent binding.

7.

If the device shaft does not turn freely, fix or replace the

device.

M16470

LINE VOLTAGE

WIRING

LOW

VOLTAGE

WIRING

GND

L2

L1

DR1

DR2

CW

S

CCW

L2

L1

ML7999

R7999

M16469

1/2 IN. MAXIMUM

TERMINATE WIRE SHIELD AT THE CONTROLLER (R7999).

SEE FIGURE 5 FOR ACTUATOR WIRING.

1

2

1

2

G

LED

Online

Configured

Meaning

Notes

Fast Blink

No

Yes

Awaiting ID signal.

Responds only to ID signal.

Slow Blink

Yes

Yes

ID signal recognized.

Monitors signals for operation or offline commands.

Steady On

No

No

Actuator has failed.

Return actuator to factory.

ACTUATOR MECHANICAL OPEN/CLOSED FIXED STOPS

M19666

ACTUATOR MECHANICAL OPEN/CLOSED FIXED STOPS

MOVED MINIMUM OF 5 DEGREES

Summary of Contents for ML7999A

Page 7: ...7 65 0239 2 ...