ML7999C UNIVERSAL PARALLEL-POSITIONING ACTUATOR

3

32-00079EF—01

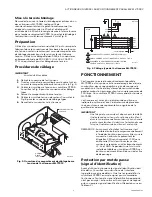

Fig. 2. V5197A Firing Rate Gas Valve, with

mounting bracket (included) and ML7999C Actuator

(not supplied), dimensions in in. (mm).

INSTALLATION

When Installing this Product...

1.

Read these instructions carefully. Failure to follow

them could damage the product or cause a

hazardous condition.

2.

Check the ratings given in the instructions and on the

product to make sure the product is suitable for your

application.

3.

Installer must be a trained, experienced service

technician.

4.

After installation is complete, check out product

operation as provided in these instructions.

WARNING

Fire or Explosion Hazard.

Can cause property damage, severe personal

injury, or death.

Tighten the hub setscrews to a torque of

60 lb-in. (7 N•m).

WARNING

Electrical Shock Hazard.

Can Cause serious injury or death.

Disconnect power supply before installation.

Location

CAUTION

Actuator Damage Hazard.

Deteriorating vapors and acid fumes can damage

the actuator metal parts.

Install actuator in areas free of acid fumes and

other deteriorating vapors.

CAUTION

Equipment Damage Hazard.

Temperature extremes will damage actuator.

Do not locate actuator where ambient temperatures

will exceed the limits listed in the Specifications

section.

CAUTION

Equipment Damage Hazard.

Excessive vibration will damage actuator.

Do not locate actuator where vibration will exceed

the limits listed in the Specifications section.

Mounting ML7999C Actuator

The actuator mounts on a 1/2 in. round or square shaft. For

shafts smaller than 1/2 in, self-centering adapters are

available for 5/16 in. and 3/8 in. shafts. For shafts larger

than 1/2 in., adapters are available for 5/8 in., 3/4 in., and

9/16 in.

CAUTION

Equipment Damage Hazard.

Lateral forces on actuator hub will damage

actuator.

Make sure actuator is mounted square with bracket

and with shaft centered in actuator hub or binding

can occur, damaging the actuator.

1.

Place the actuator over the shaft, see Fig. 3.

2.

Position and seat the actuator.

3.

Rotate the shaft to match the actuator position.

4.

Install the mounting bracket accessory (not

included), if needed. See Fig. 4.

5.

Partially tighten hub setscrews to ensure actuator

seats firmly against mounting bracket with shaft

centered in hub.

6.

Tighten the anti-rotation bolt to the torque

recommendation for the selected bolt/nut.

7.

Tighten the hub setscrews against the shaft to a

torque of 60 lb-in.

10-5/16

(277)

4-27/32 (123)

6-7/16 (165)

2-1/2 (64)

7-1/8

(181)

3-25/32

(96)

M17528