ML7999C UNIVERSAL PARALLEL-POSITIONING ACTUATOR

32-00079EF—01

4

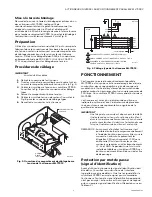

Mounting the ML7999C Actuator on

V5197A Firing Rate Gas Valve. (Fig. 2)

WARNING

Explosion Hazard and Electrical Shock Hazard.

Can cause severe injury, death or property

damage.

1. Turn off gas supply before starting installation.

2. Disconnect power supply for valve actuator

before beginning installation and wiring. More

than one disconnection can be involved.

1.

Attach the mounting bracket for the ML7999C Actu-

ator (supplied with the V5197 Valve) in the position

that best suits the valve location, access space and

wiring requirements.

2.

Place the short end of the V5197 valve drive stem in

the top of the V5197 Valve drive so that the

rectangular portion of the drive stem is inside the

valve drive.

3.

Mount the ML7999C Actuator on the V5197 Valve

and secure the actuator to the mounting bracket with

the supplied screws.

4.

Wire the ML7999C Actuator per the instructions in

the Wiring section.

5.

Restore power to the system.

Fig. 3. Mounting ML7999C.

Fig. 4. Mounting ML7999C with mounting

bracket accessory.

WIRING

WARNING

Electrical Shock Hazard.

Can cause severe injury or death.

Disconnect power supply before installation.

All wiring must comply with local electrical codes,

ordinances and regulations. The ML7999C is designed for

used with a Class 2 power supply for low voltage. Voltage

and frequency of the transformer must correspond with the

characteristics of both the actuator and the power supply.

IMPORTANT

Run line voltage and low voltage wiring in separate

conduit to avoid signal interference.

Earth Ground

Earth ground is required for proper operation of the

ControLinks™ system. Earth ground provides a connection

between the subbase and the control panel of the

equipment. The earth ground must be capable of

conducting enough current to blow the fuse or breaker in

the event of an internal short.

1.

Use wide straps or brackets to provide minimum

length, maximum surface area ground conductors. If

a leadwire must be used, use 14 AWG copper wire.

2.

Make sure that mechanically tightened joints along

the ground path are free of nonconductive coatings

and protected against corrosion on mating surfaces.

Shield Ground

Connect the shield ground of the ML7999C Actuator(s),

Remote Reset, Manual Potentiometer, Controller 4-to-20

mA and Auxiliary 4-to-20 mA inputs to the earth ground

strip provided in the Q7999 Universal Subbase. Connect

the shield at the controller end only. See Fig. 6.

Preparation

Use OEM-supplied 1/2 in. conduit connectors in the low-

and line- voltage base openings; the motor has separate

line- and low-voltage wiring compartments. Use Belden

9535, 5-conductor, 100% shield coverage, 300V, 80°C

(UL2464, CSA PCC FT4), or equivalent for low voltage

wiring.

Wiring Procedures

IMPORTANT

Device must be hardwired.

1.

Remove the cover from the actuator.

2.

Pull back the snap-locks while opening the low-volt-

age compartment. See Fig. 5.

3.

Wire the low-voltage circuit to the R7999. See Fig. 6

for typical wiring connections.

4.

Close the low-voltage compartment.

5.

Wire the line-voltage circuit. See Fig. 6 for typical wir-

ing connections.

6.

Replace the cover on the actuator.

M16467A

LOCK WASHER OR

CAPTIVE NUT

(NOT PROVIDED)

M16468A

LOCK WASHER OR

CAPTIVE NUT

(NOT PROVIDED)