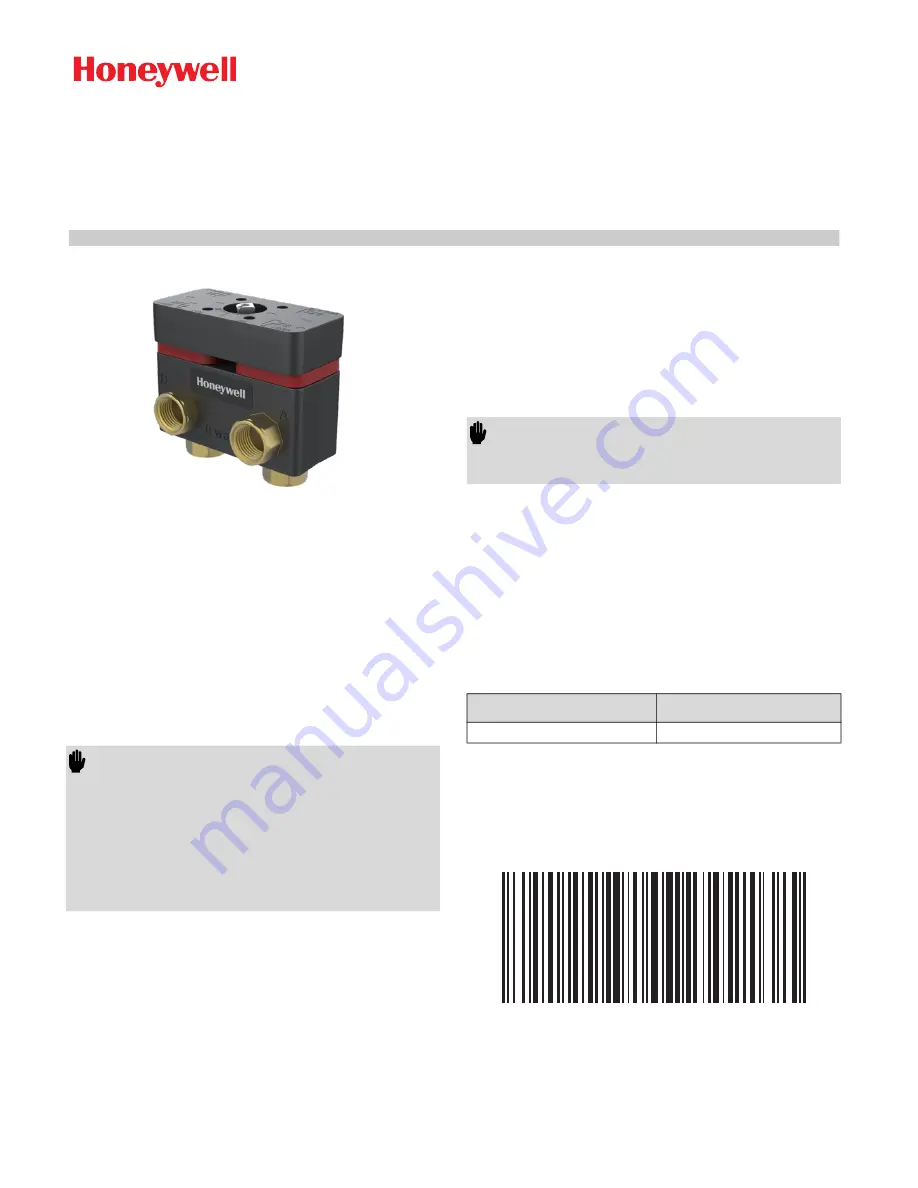

VB6 SERIES 6-WAY CONTROL BALL VALVES

AND ACTUATORS

INSTALLATION INSTRUCTIONS

® U.S. Registered Trademark

Copyright © 2021 Honeywell Inc. • All Rights Reserved

31-00380M-02

Printed in USA

Application

The VB6 6-Way Control Ball Valves regulates hot

and chilled water with glycol solutions up to 60%

in heating, ventilating, and air conditioning

(HVAC) systems.

These valves ship with a direct coupled actuator

factory installed for modulating control. The valve

is designed to be used exclusively with

MN7510A2001 actuator.

Application Notes

IMPORTANT:

Valve sizing is important for correct system

operation. Undersized valves do not have suf

-

ficient capacity at maximum load. Oversized

valves do not have sufficient authority over

the load in modulating applications.

Oversized valves can cause excessive cycling

and the seat and ball can be damaged because

of the restricted opening.

Proper Use

These valves are intended for use in chilled water

and hot water closed loop applications only, with

a media temperature range of 0 ºF to +212 ºF (18

ºC to 100 ºC), and static pressures up to 600 psi.

These valves are to be operated with the Honey

-

well MN7510A2001 actuator only.

Water should be properly filtered, treated and

conditioned for good operating performance,

according to local conditions, and recommenda

-

tions of the boiler or chiller manufacturers. The

installation of strainers and filters is recom

-

mended.

IMPORTANT:

The presence of excessive iron oxide (red rust)

in the system voids the valve warranty.

Required Operating Torque

The VB6 series 6-way control ball valves are to be

operated with the Honeywell MN7510A2001

actuator only

These valves use a patented seat design that

reduces the torque needed. The nominal required

operating torque is 88 lb-in.

Table 1. Close off Pressure

Flow Characteristic

The VB6 series 6-way Ball Valves have true equal

percentage flow characteristic, thanks to preci

-

sion machined metal discs in front of the ball.

Valve Size

Close off Pressure

1/2 inch and 3/4 inch

200 psi (1380 kPa)

31-00380M-02