SET OPERATING RANGE

B

2.

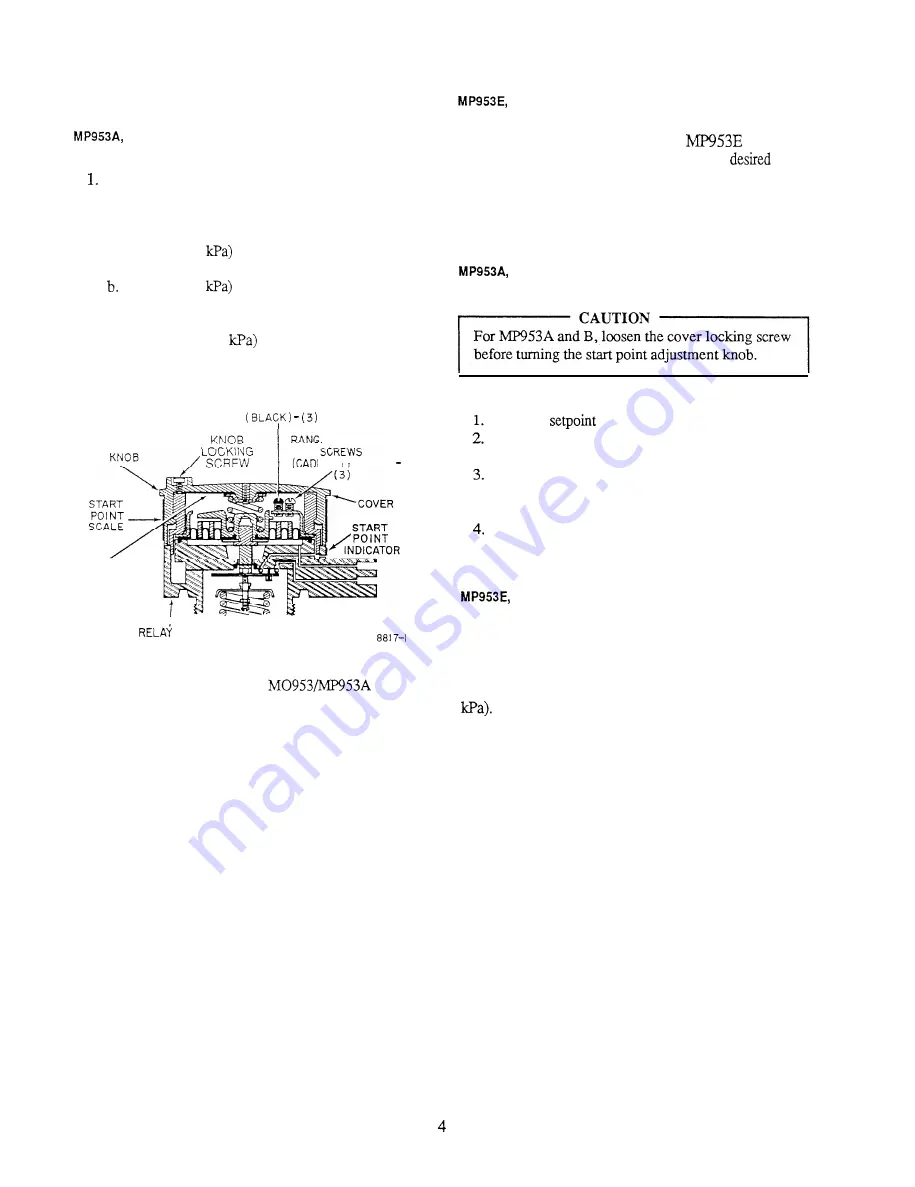

Use Wrench 301572A to loosen the cover locking

screw (Fig. 2).

Unscrew the start point adjustment knob until thread

is disengaged. Remove knob.

a. For

3

psi (21

range, back all range adjustment

screws off to friction stop.

For 5 psi (34

range, back only the black range

adjustment screws to stop and tighten the outer,

cadmium-plated range adjustment screws.

c. For 10 psi (69

range, tighten all range

adjustment screws.

F

Change the operating range of

and F by

replacing the feedback spring with one for the

range

(see REPAIR).

ADJUST START POINT

B

RANGE ADJUSTMENT SCREWS

START POINT

ADJUSTMENT

E ADJUSTMENT

M IUM PLATED)

RANGE

ADJUSTMENT

INSTRUCTIONS

SHOWN HERE

BODY

Fig. 2. Adjustment Points of

and B

Gradutrol Relay.

Reinstall

knob.

Tighten knob by turning it until it is seated on relay

body (Fig.

2).

Loosen knob (maximum of one turn) until start point

of correct scale range lines up with start point

indicator.

Tighten knob locking screw until it engages relay

body. Do not overtighten.

F

Set the start point on the positioner to the value shown on

the job drawings. Critical applications and feedback spring

changes mightrequire fine-tuning the

start

point. Each click

of the start point knob will adjust the start

point

0.25 psi (1.7

75-5500