TROUBLESHOOTING

EQUIPMENT NEEDED

Troubleshooting procedures require Pressure Gage

14003519 (0 to 30 psi to 207

SYMPTOMS AND CORRECTIVE

ACTION

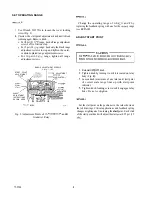

Figures 3 and 4 show troubleshooting flowcharts.

CHECK

ACTUATOR

IS SECURELY MOUNTED

AND

IS

PROPERLY LATCHED

N O

PRESSURETO

DOES

RANGE VALUE

LOOSEN

COVER. SLOWLY

TURN COVER SCALE TO

BELOWZERO START POINT.

ADJUST POS

I

TIONER

START POINT

MINIMUM VALUE

I

P O S I T I O N E R S T A R T

POINT IF NECESSARY

NO

REMOVE ANY FOREIGN

MATERIAL;

DISC,

AND STEM; AND/OR

REPACK VALVE

Fig. 3. Troubleshooting Flowchart for

B, E, F (with

Relay/Positioner).

5