SERIES 71, 72, AND 76 MODUTROL IV™ MOTORS

63-2640—07

2

ORDERING INFORMATION

When purchasing replacement and modernization products from your TRADELINE® wholesaler or distributor, refer to the

TRADELINE® Catalog or price sheets for complete ordering number.

If you have additional questions, need further information, or would like to comment on our products or services, please write or

phone:

1.

Your local Honeywell Automation and Control Products Sales Office (check white pages of your phone directory).

2.

Honeywell Customer Care

1885 Douglas Drive North

Minneapolis, Minnesota 55422-4386

In Canada—Honeywell Limited/Honeywell Limitée, 35 Dynamic Drive, Toronto, Ontario M1V 4Z9.

International Sales and Service Offices in all principal cities of the world. Manufacturing in Australia, Canada, Finland, France,

Germany, Japan, Mexico, Netherlands, Spain, Taiwan, United Kingdom, U.S.A.

SPECIFICATIONS

Models:

TRADELINE models are selected and packaged to

provide ease of stocking, ease of handling and maximum

replacement value. TRADELINE model specifications are the

same as those of standard models unless specified otherwise.

IMPORTANT

The specifications given in this publication do not

include normal manufacturing tolerances. Therefore,

an individual unit may not exactly match the listed

specifications. Also, this product is tested and

calibrated under closely controlled conditions and

some minor differences in performance can be

expected if those conditions are changed.

Modutrol IV Order Number Guide:

See Table 4.

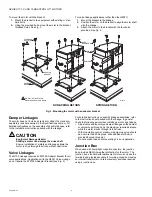

Dimensions:

Lifetime

60,000 Full Stroke Cycles

Repositions: 1.5 Million

Controller:

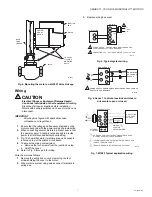

These motors can be used with any electronic

controller that provides a stable noise-free proportional

current output as specified in Electrical Ratings, Input

Range below.

Electrical Ratings:

Power Consumption: See Table 1.

Input Range:

Current, Nonadjustable: 4 to 20 mA nominal, 25 mA

maximum.

Current, Adjustable: 4 to 20 mA adjustable, 50 mA

maximum.

Zero/Null (Motor Closed): 0.0 to 18 mA.

Span: 1.8 to 20 mA.

Voltage, Nonadjustable: 2 to 10 Vdc.

Input Impedance:

4 to 20 mA Input: 100 ohms.

2 to 10 Vdc Input: 400K ohms.

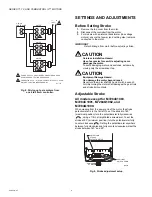

Auxiliary Switch Ratings (in Amps):

Stroke:

Most models available with field adjustable strokes

from 90° to 160°. Stroke adjusted by means of

potentiometers located in the wiring compartment.

Timing:

Nominal 30 seconds for 90° stroke and 60 seconds

for 160° stroke.

Dead Weight Load On Shaft:

200 lb (91 kg) on motor power

or auxiliary end; maximum combined load of 300 lb (136 kg).

Ambient Temperature Ratings:

-40 to 150°F (-40 to 66°C).

Shaft:

3/8 in. (9.5 mm) square.

Motor Rotation:

Closed: Counterclockwise rotation limit as viewed from motor

power end.

Mechanically Normally Closed: Spring return. Normally closed

motors rotate to closed position on power loss.

Electrically Normally Closed: Both spring return and non-

spring motors return to closed position on minimum signal.

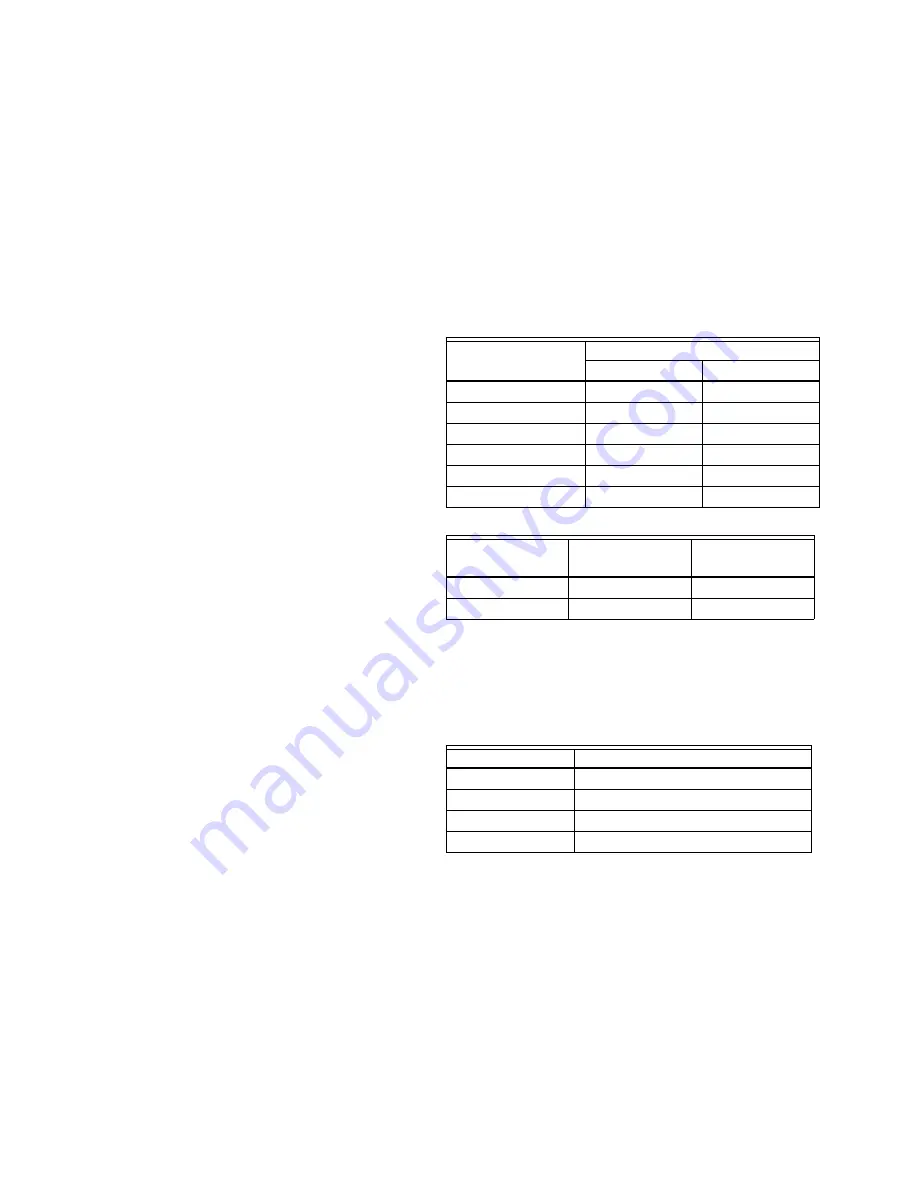

Table 1. Series 72 Modutrol IV Motor Power

Consumption Ratings (at 120 Vac, 50/60 Hz).

Table 2. Auxiliary Switch Ratings (in Amps).

a

40 VA pilot duty, 120/240 Vac on opposite contact.

Approvals:

Underwriters Laboratories Inc. Listed: File No. E4436; Guide

No. XAPX for USA and Canada.

U.S. Patents: pending

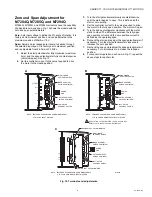

Table 3. Primary 50017460-001 Color Code

Model

Power Consumption

VA

Watts

M7261

15

13

M7282

20

18

M7284

15

13

M7285

20

18

M7286

20

18

M7294

15

13

One Contact

Rating

a

120V

240V

Full Load

7.2

3.6

Locked Rotor

43.2

21.6

Lead Color

Primary Voltage

Brown

24 VAC

White

120 VAC

Blue

230 VAC

Black

Common