MP953A,B,C,D PNEUMATIC ACTUATORS

Manufactured for and on behalf of the Environmental and Combustion Controls Division of Honeywell Technologies Sàrl, Rolle, Z.A. La Pièce 16, Switzerland by its Authorized Representative:

Automation and Control Solutions

Honeywell GmbH

Böblinger Strasse 17

71101 Schönaich

Germany

Phone: (49) 7031 63701

Fax:

(49) 7031 637493

http://ecc.emea.honeywell.com

Subject to change without notice. Printed in Germany

EN0B-0552GE51 R1210

1

1

1

2

2

2

ALL screws “1” and “2”

tightened.

Three screws “1”

backed off to friction stop.

ALL screws “1” and “2”

backed off to friction stop.

70 kPa

(10 psi)

35 kPa

(5 psi)

21 kPa

(3 psi)

operating

range

range adjustment

start point adjustment

One graduation of scale on the start point adjustment knob represents a

start point change of 7 kPa. One complete turn of the start point

adjustment knob represents a start point change of 7 kPa.

One graduation of scale on the start point adjustment knob represents a

start point change of 2 kPa. Three complete turns of the start point

adjustment knob represent a start point change of 62 kPa

(note auxiliary scale).

One graduation of scale on the start point adjustment knob represents a

start point change of 3.5 kPa. Two complete turns of the start point

adjustment knob represent a start point change of 70 kPa.

adjustment screw

set screw

Fig. 6. Adjustments of ranges and start points

Adjustment Check

1.

Install a gauge in the pilot air line (P).

2.

Adjust the set screw (see Fig. 6) so that travel just begins.

3.

Increase pilot pressure (P) until travel is complete. If the

adjustment is correct, the gauge should read this pressure

within ±5 kPa of the start point pressure plus the range

setting.

EXAMPLE:

Range setting 35 kPa start point setting 21 kPa.

The gauge should then read 56±5 kPa after the travel is

completed.

4.

If the measured pressure should not be within the

permissible variation, fine adjustments must be done (if

necessary) using the start point adjustment knob.

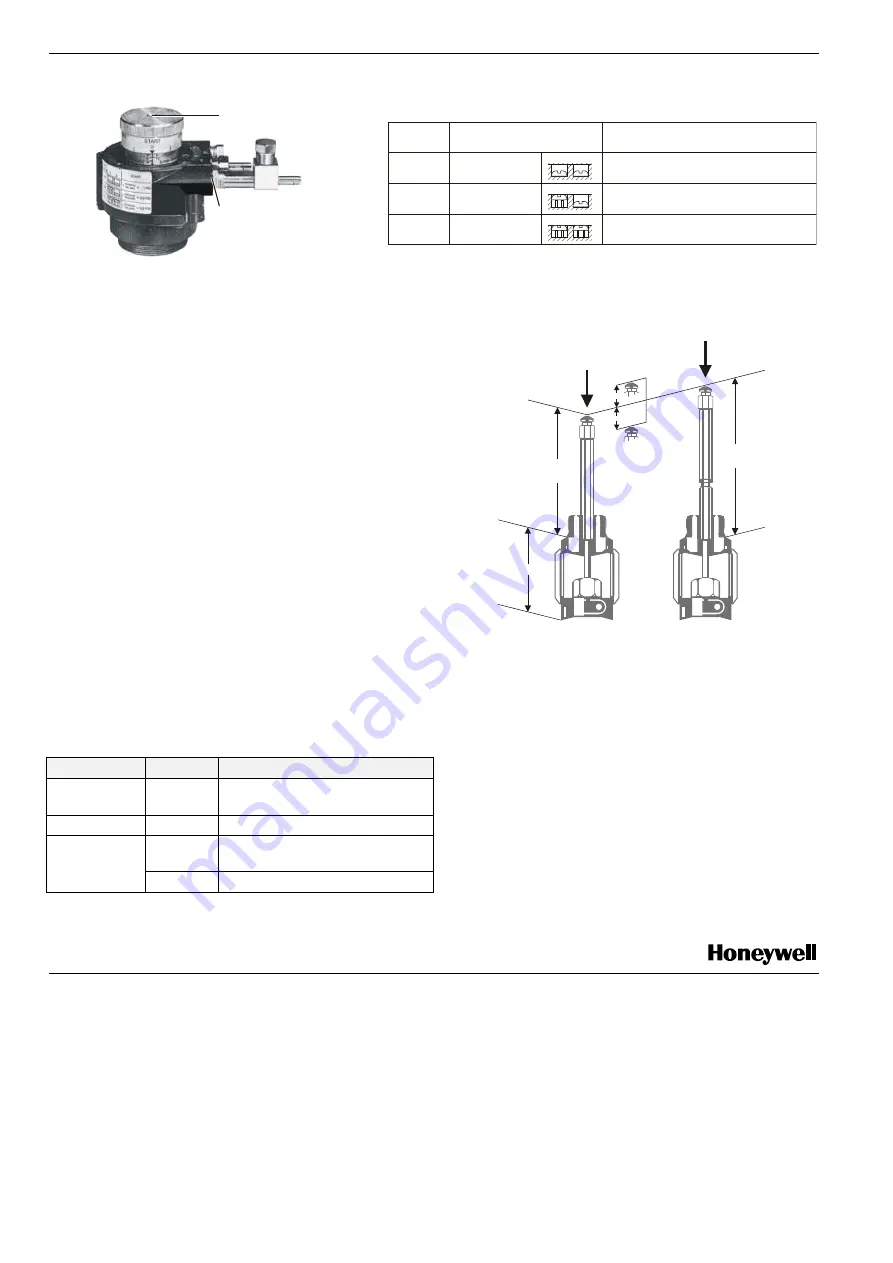

MOUNTING WITH EXTENSION YOKE

For working temperatures of 150 to 220 °C (300 to 425 °F),

use of an extension yoke is mandatory for the MP953A,C (5"

and 8") and the MP953B,D actuators to protect the diaphragm

against excessive heat. Screw the stem extension (for the 5"

size) onto the stem, with the stem either pulled out or pushed

in (see Fig. 7), and adjust dimension "y" to the value listed in

Table 6. Lock stem extension into place by tightening the hex

nut, and attach the yoke.

Table 6. Mounting actuators with extension yoke

actuator

"y" (mm)

valve

MP953A,C, 5"

89

V5011R,S, V5328A, V5016A,

V5025A, V5049A

MP953B,D

107

V5013R,E, V5329A,C, V5050A

133

V5011R,S, V5328A, V5016A,

V5025A, V5049A

MP953A,C, 8"

151

V5013R,E, V5329A,C, V5050A

y

70 mm

y

C5’’

D

C8’’

V5011A

V5049A

V5328A

V5013A

V5049B

V5050A

V5329A,C

travel

travel

Fig. 7. Extension yoke