IB-52

Installation and Maintenance

REPAIR AND ADJUSTMENT PROCEDURES FOR HONEYWELL

OR MP-953F PNEUMATIC OPERATORS USED ON ARMSTRONG HUMIDIFIERS

This bulletin should be used by experienced personnel as a

guide to the repair and adjustment of Honeywell

or MP-953F pneumatic operators for Armstrong humidifiers.

Selection or installation of equipment should always be

accompanied by competent technical assistance.

We encourage you

to contact Armstrong or its local representative if further

information is required.

WARNING:

BE SURE THAT STEAM SUPPLY VALVE FOR THE HUMIDIFIER IS

BEFORE ATTEMPTING TO MAKE ANY REPAIRS TO THE

OPERATOR.

Maintenance procedures for the Honeywell pneumatic operator

include:

removing the operator from the bonnet, installing the

operator on the bonnet, replacing steam seals, changing operator

springs,

replacing the diaphragm, replacing the rolling seal, and

replacing the valve and seat.

I.

REMOVING THE PNEUMATIC OPERATOR

Many repair procedures require that the operator be removed

from the bonnet assembly.

To remove the operator, perform

the following steps.

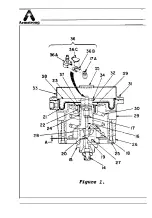

Refer to Figure 1 (see back cover) to

locate the parts by item numbers.

1.

Turn oft steam to the humidifier.

2.

Turn off the instrument air and disconnect the line

from the operator.

3.

Loosen the two set screws (27) on both sides of tne

operator base (26).

4.

Remove operator plug (35) from the

or open the

access plate on the MP-953B or MP-953F.

5.

Insert a screwdriver into the slot at the top of the

yoke assembly (36).

Hold the operator and turn

screwdriver

clockwise until the yoke assembly

disengages from the operator.

6.

Lift the operator from the bonnet.

(See Figure 1 on back cover.)