MSXX10, MSXX20 SERIES

63-2607—26

6

Select Actuator Control Signal

MS41XX, MS71XX, MS75XX, MS81XX

These actuators are available in two control types:

— Standard: includes mode selection dial to select the

desired input signal.

— Enhanced: includes different mode selection dial to

select the desired input signal. Also includes dials for

adjusting the input signal zero and span.

NOTE:

Selections are made using a dial that appears on

both the front and back of the actuator (see Fig. 4).

For available options, see Table 5.

To select the control signal simply turn the mode selection

dial to the desired control signal (as indicated on the device

label).

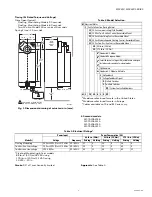

Fig. 4. Dials for control signal and zero/span.

MS31XX

These actuators are available with Sylk address selection

pot and Range/Direct control selector pot. The Range pot

has 3 ranges that cause the actuator to be direct acting

and 3 ranges to cause the actuator to be reverse acting.

NOTE:

When Direct range pot called out, a 0 to 100%

command would associate 0% with full spring

return and 100% with position farthest from

spring return. When Reverse range pot called out,

a 0 to 100% command would associate 100%

with full spring return and 0% farthest from spring

return.

There are 15 effective Sylk addresses that you can choose

from. For example, to select Sylk address 11 move the

range pot to Direct control selection and Sylk address pot

to G.

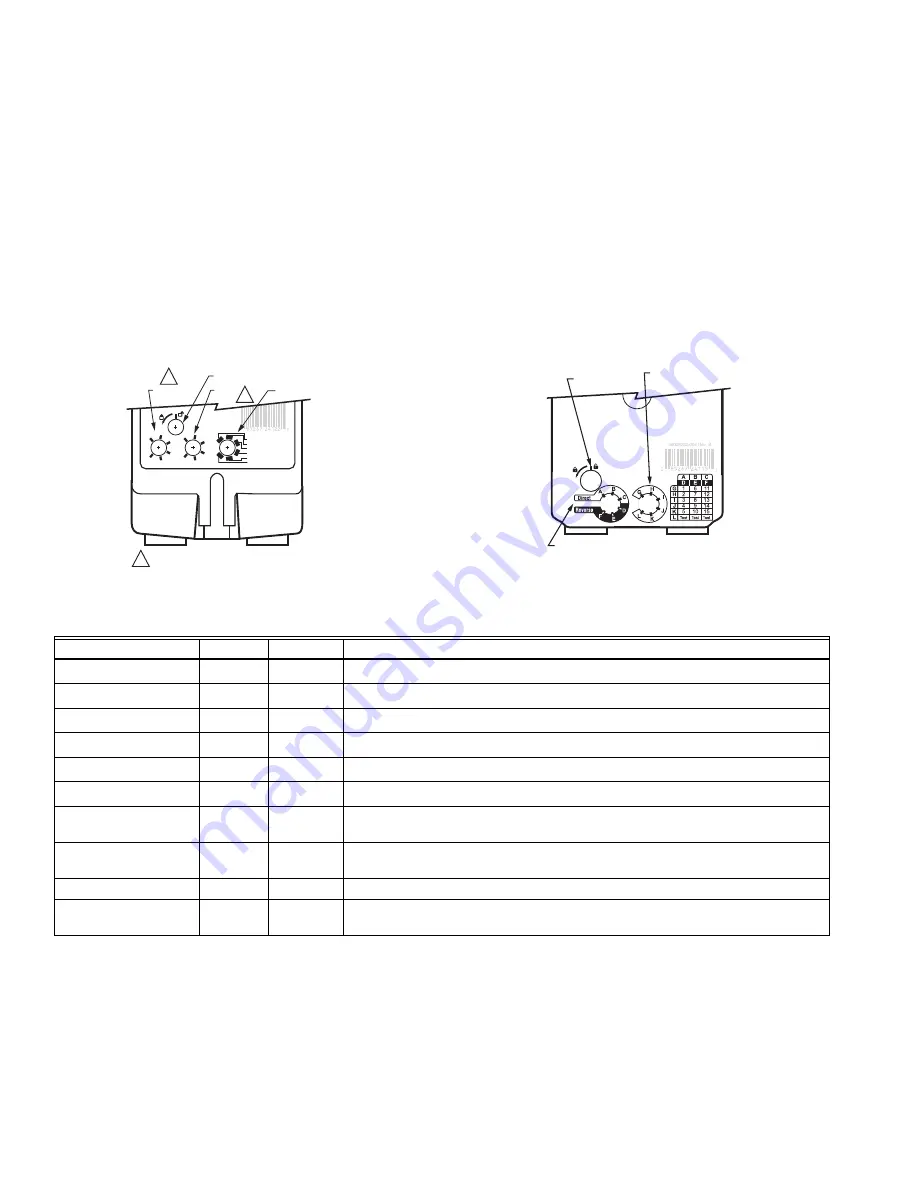

Fig. 5. Dials for control signal.

Table 5. Actuator Control Signal Selections.

a

Feedback: MS75XXA,H and U.S. S… models are 2-10 Vdc, MS75XXB,E and European S… models are 0-10 Vdc.

b

Feedback: MS75XXA,H and U.S. S… models are 10-2 Vdc, MS75XXB,E and European S… models are 10-0 Vdc.

c

When operating in Modulating mode, the feedback signal matches the control signal.

Non-Standard Stroke

Mechanical Stroke Limit Reduction

For applications requiring a span less than 95 degrees, a

simple adjustment can be made. When the rotational

mounting of the shaft coupling is changed, the actuator

drives less than the full 95 degrees stroke.

The stroke is adjustable in 5 degree increments. Once

adjusted, the actuator drives until the shaft coupling

reaches the mechanical stop (part of the housing). The

stop causes the motor to discontinue driving and the shaft

coupling drives no farther. When the actuator returns, it

stops at the fail-safe position.

32007163-011 Rev. C

Modulating, Forward

Modulating, Reverse

Floating, Forward

Floating, Reverse

Service

Auto Adapt

Start

0V

10V

2V

32V

Span

M20954A

ZERO

LOCKING PIN

SPAN

MODE SELECT

1

1

1

SPAN AND ZERO EXIST ONLY

ON MODELS MS75XXE,H.

M34296A

LOCKING PIN

SYLK ADDRESS

SELECTION

RANGE/DIRECTION

CONTROL SELECTOR

Mode Options

Standard Enhanced

Details

Floating: forward

X

a

X

a

Series 60 control. Power to terminal 4 drives toward spring return position.

Floating: reverse

X

b

X

b

Series 60 control. Power to terminal 3 drives toward spring return position.

Modulating: 0-10 Vdc X

c

Series 70 control. 0 Vdc signal drives toward spring return position.

Modulating: 10-0 Vdc X

c

Series 70 control. 10 Vdc signal drives toward spring return position.

Modulating: 2-10 Vdc X

c

Series 70 control. 2 Vdc signal drives toward spring return position.

Modulating: 10-2 Vdc X

c

Series 70 control. 10 Vdc signal drives toward spring return position.

Modulating: forward

X

Voltage input with adjustable zero and span. Minimum signal drives toward

spring return position.

Modulating: reverse

X

Voltage input with adjustable zero and span. Maximum signal drives toward

spring return position.

Service

X

Actuator hub stops in place and ignores control signal changes.

Auto-adapt

X

For setup only. Rescales to allow full input signal over mechanically limited

stroke.