MSXX10, MSXX20 SERIES

7

63-2607—26

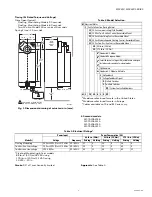

To set the fail-safe position, proceed as follows:

1.

Remove the retainer clip from the shaft coupling and

set it aside for later use.

2.

Remove shaft coupling from the actuator.

3.

Rotate the coupling to the desired fail-safe position,

aligning it based on the stroke labelling. See Fig. 6.

NOTE:

The shaft coupling location determines the

travel span.

EXAMPLE:Setting shaft coupling to an approximate

fail-safe position of 35 degrees (as indi-

cated on the housing) limits stroke to 60

degrees. (See Fig. 6)

4.

Install the shaft coupling at this position.

5.

Replace the retainer clip on the shaft coupling using

the groove of the coupling.

6.

If necessary, replace the holder and position indicator

on the shaft coupling.

Fig. 6. Stroke reduction.

Adjustable Zero and Span

(Enhanced Modulating Models

only

)

These actuators have the capability of adjustable zero and

span. Fig. 4 shows the dials. These dials are present only on

the Enhanced Modulating models. A basic description of

these dials follows:

— Zero: Sets input voltage to define the 0% angle of

rotation. It is factory set to 0 Vdc, and can be adjusted up

to 10 Vdc.

— Span: Adjusts motor response to travel full stroke

through the selected input span. It is factory set to 10

Vdc, and is adjustable from 2 to 32 Vdc.

SET ADJUSTABLE ZERO AND SPAN

1.

Apply 24 Vac to the actuator.

2.

Turn the zero dial (see Fig. 4) past the desired start

point.

3.

Using either a controller or signal generator, apply an

input signal equal to the start point signal.

4.

Slowly adjust zero toward the minimum setting until

the actuator hub begins to move.

5.

Turn the span dial (see Fig. 4) to the

minimum setting (2 Vdc).

6.

Using either a controller or signal generator, apply an

input signal equal to the desired end point signal.

7.

Allow the actuator to open fully.

8.

Slowly adjust span toward the maximum setting until

the actuator hub moves slightly from fully open.

9.

Carefully adjust span knob toward minimum until the

actuator hub returns to fully open.

Auto-Adapt

When using these actuators for standard stroke

applications, this function can be ignored. When it is

desirable to use a mechanically limited stroke (see

Mechanical Stroke Limit Adjustment section), it is possible

to use the Auto-Adapt feature to rescale the input signal

over the new limited stroke.

1.

Rotate actuator control signal dial to Auto-Adapt.

NOTE:

The actuator will drive open, then closed to

establish the new open and closed positions.

2.

Return the actuator control signal dial to the desired

input signal position.

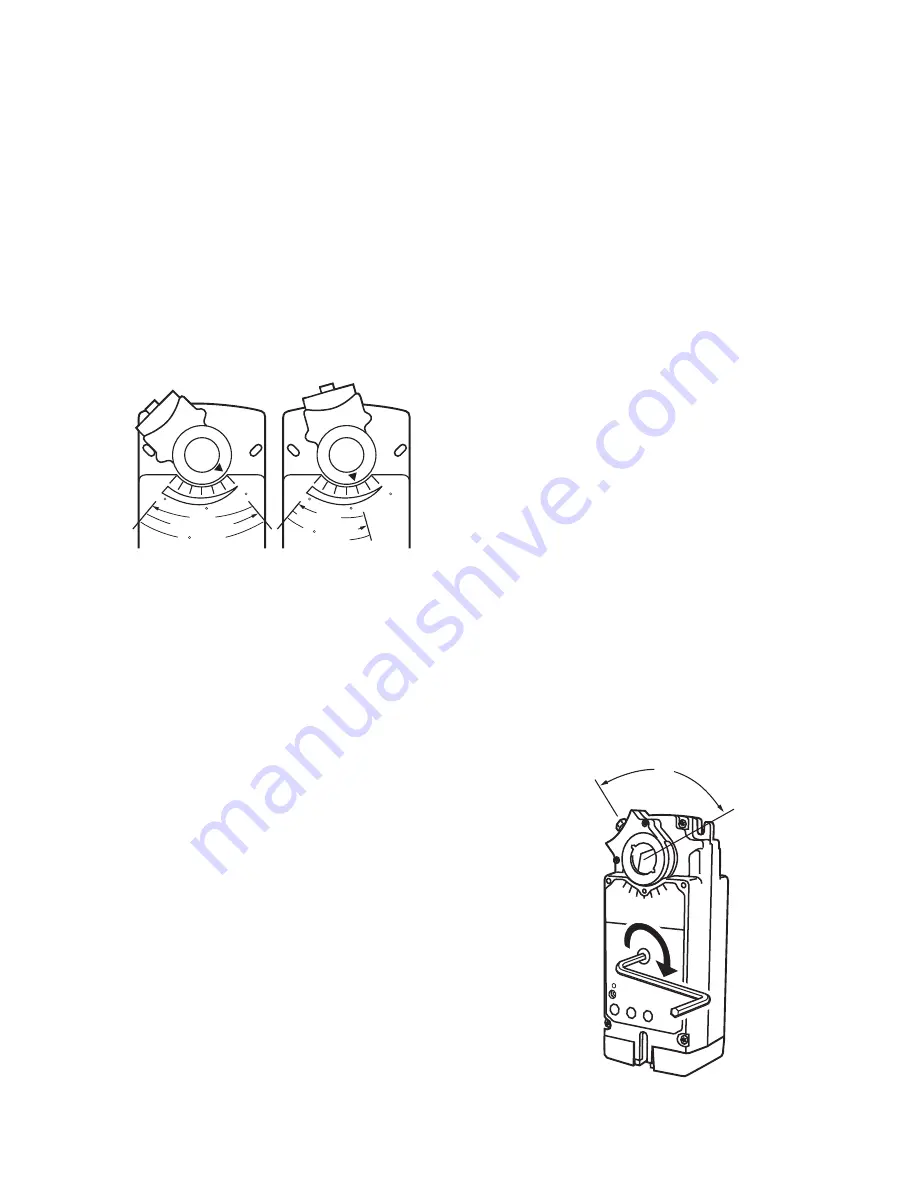

Manual Positioning

The actuator can be operated with no power present. Use

this feature during installation or to move and lock the

damper or valve shaft position when there is no power.

To operate the manual positioning:

1.

If the power is on, turn it off.

2.

Insert supplied hex wrench (key) as shown in Fig. 7.

3.

Rotate key in the direction indicated on the cover.

4.

Once the desired position is reached, hold the key to

prevent the spring return from moving the actuator.

5.

With the key held in place, use a screwdriver to turn

the gear train lock pin in the indicated direction until

the detent is reached.

NOTE:

At the detent, the pin resists further rotation.

6.

Remove the key without rotating it further.

To release the manual positioning with no power present:

1.

Insert supplied key.

2.

Turn key 1/4 turn in the direction indicated on the

cover.

3.

Remove key without engaging the gear train lock pin.

4.

The spring will return actuator to the fail-safe posi-

tion.

NOTE:

Once power is restored, the actuator will

return to normal automated control.

Fig. 7. Manual positioning.

DRIVE

SPRING RETURN

90 STROKE

45

M22065

90

0

DRIVE

SP

RIN

G RETURN

60

STROKE

45

90

0

M32268

ROTATING

95