Diagnostic Indicator Display

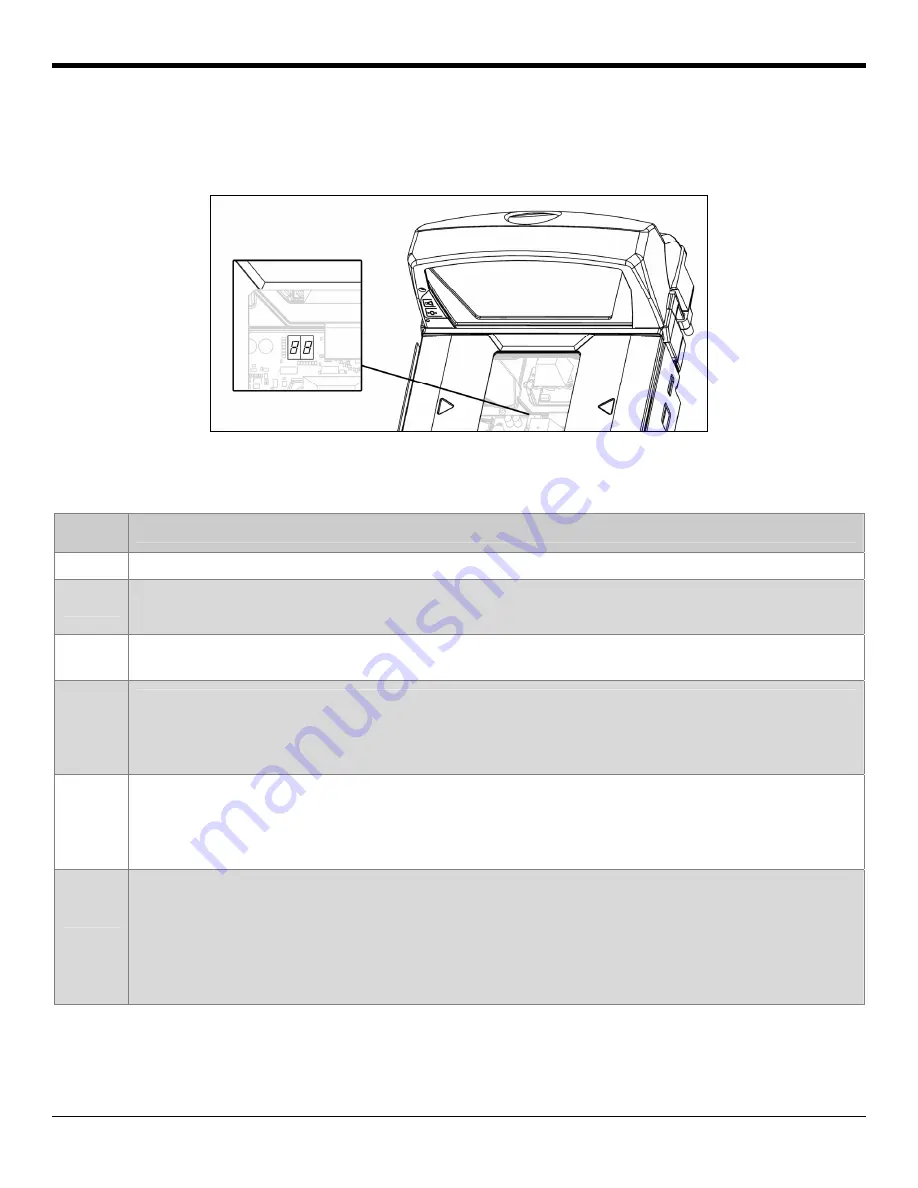

There is a two-digit error code display located under horizontal output window near the top of the platter (see

figure below).

Figure 33. Error Code Display

The following is a list of possible error codes and their meanings. Some errors will require immediate scanner

maintenance.

Error

Code

Description

01 Reserved

02

RAM ERROR – The scanner’s Random Access Memory (RAM) is tested as faulty. Return the unit

for repair at an authorized service center.

03

PROGRAM ERROR – The scanner’s software program is failing. Return the unit for repair.

04

INTERFACE ERROR – After power up and any application exit (e.g. MetroSet, etc.), the scanner

checks the interface hardware with that chosen in configuration. If they do not agree, an interface

error exists. Correct this problem by getting the proper hardware interface OR programming

MS2421/MS2422/MS2431 configuration for the proper interface hardware attached.

05

CONFIGURATION ERROR – The non-volatile configuration memory did not agree with the data

last saved. Default configuration data is then used and the scanner continues operating. This

error is also accompanied by three beeps. This error will remain during operation as a reminder

that this power cycle is scanning against a default-generated configuration.

06

COMMUNICATION ERROR – The RS232 data line is being held active. This causes the scanner

to read a “break” signal constantly and continuous attempts are made to enter MetroSet

configuration mode. A short on the RX Data line can cause this condition. It can also be the result

of a laptop in power save mode. The scanner will abort attempts to enter configuration mode after

a short timeout. The scanner can automatically recover from this condition once the short in the

RX Data line is corrected.

38

Summary of Contents for MS2421

Page 1: ...MS2421 MS2422 MS2431 Bar Code Scanner Installation and User s Guide ...

Page 18: ...14 ...

Page 48: ...44 ...

Page 54: ...50 ...

Page 62: ...58 ...

Page 64: ...60 ...

Page 66: ...62 ...

Page 71: ......

Page 72: ...Honeywell Scanning Mobility 90 Coles Road Blackwood NJ 08012 00 05311 Rev B August 2009 ...