N05010/N10010 DAMPER ACTUATORS FOR MODULATING AND FLOATING/2-POSITION CONTROL

Table 1 describes, for the floating mode, the shaft adapter

behavior ("stops," rotates "CCW," or rotates "CW") in

dependence upon the control signals applied to terminals 3

and 4 and upon the function selection switch setting.

Table 2 describes, for the 2-position mode, the shaft adapter

behavior ("stops," rotates "CCW," or rotates "CW") in

dependence upon the control signals applied to terminals 3

and 4 and upon the function selection switch setting.

Table 3 describes, for the modulating mode, the shaft adapter

behavior ("stops," rotates "totally CCW," rotates "totally CW,"

runs to "proportional" position, or runs to "50%" of max.

stroke) in dependence upon the control signals applied to

terminals 3 and 4 and upon the function selection switch

setting.

Table 1. Shaft adapter behavior in the floating mode

control signal at

switch settings

terminal 3

terminal 4

0[2]...10 V

Dir

Service / Off

Rev

10...0[2] V

open open

-- stops

stops

stops --

open 24

Vac/dc

-- CCW

stops CW --

24 Vac

open

-- CW

stops

CCW --

Table 2. Shaft adapter behavior in the 2-position mode

control signal at

switch settings

terminal 3

terminal 4

0[2]...10 V

Dir

Service / Off

Rev

10...0[2] V

24 Vac

open

-- CW

stops

CCW --

24 Vac

24 Vac/dc

-- CCW

stops CW --

Table 3. Shaft adapter behavior in the modulating mode

control signal at

switch settings

terminal 3

terminal 4

0[2]...10 V

Dir

Service / Off

Rev

10...0[2] V

open

totally CCW

--

stop

--

totally CCW

open

24 Vac/dc

50% -- stop -- 50%

open

totally CCW

--

stop

--

totally CW

< min. control signal plus 0.24 V

24 Vac/dc

50% -- stop -- 50%

open

proportional

-- stop --

proportional

between min. control signal plus 0.24 V

and max. control signal minus 0.24 V

24 Vac/dc

50% -- stop -- 50%

open

totally CW

--

stop

--

totally CCW

> max. control signal minus 0.24 V

24 Vac/dc

50% -- stop -- 50%

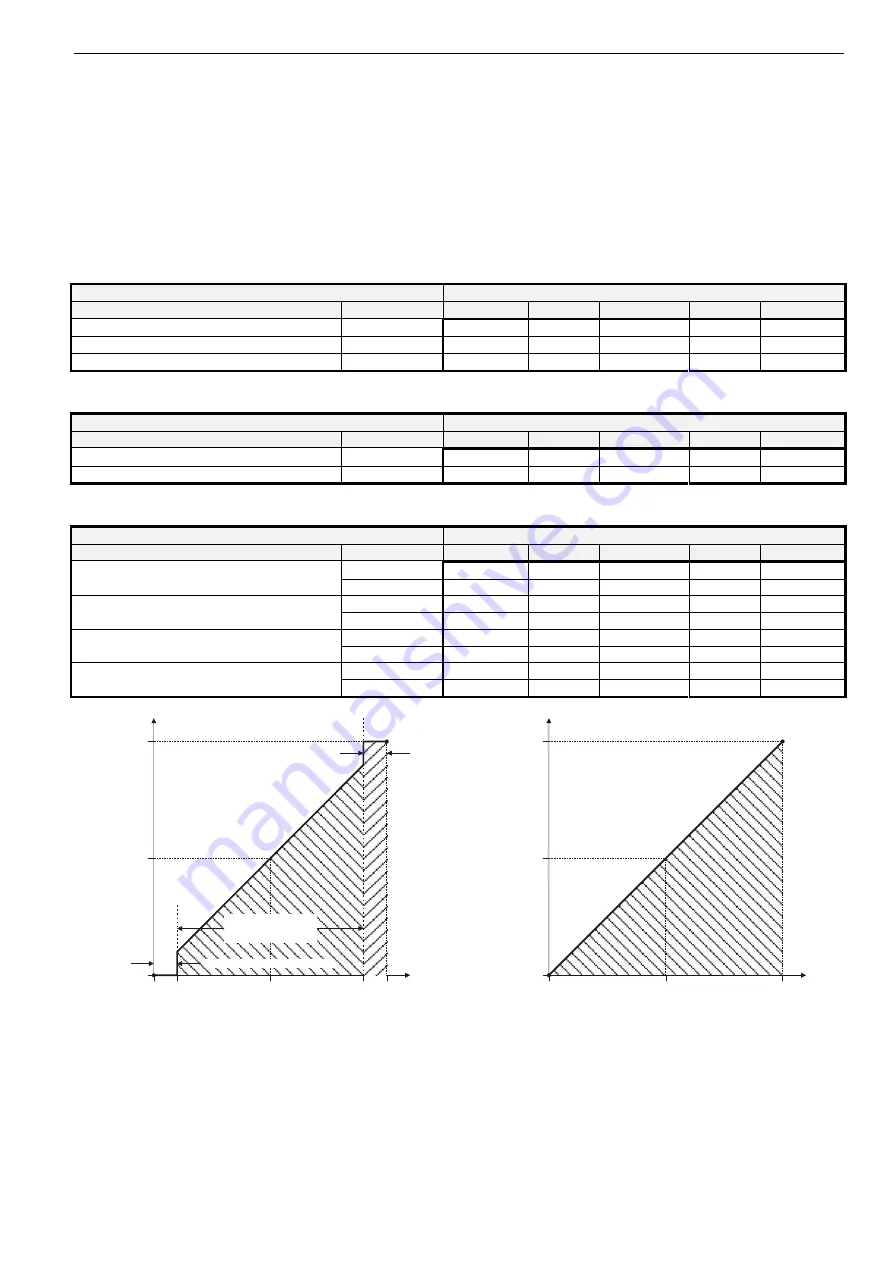

0

0.24

0

50

100

5.0

10.0

9.76

upper dead band (9.76 to 10.0 V)

control signal (V)

fin

a

l

po

si

ti

on of sha

ft ada

pt

er

(% of ma

x.

stroke

)

range of proportional

actuator movement

(0.24 to 9.76 V)

lower dead band (0 to 0.24 V)

Fig. 4. Final shaft adapter position in dependence upon

control signal (example function selection switch setting

of 0...10 V)

0

0

50

100

5

10

feedback signal (V)

cur

rent

po

s

it

io

n

of

sh

af

t

a

dap

te

r (

%

o

f max.

str

o

k

e

)

Fig. 5. Feedback signal in dependence upon current

position of shaft adapter (example function selection

switch setting of 0...10 V)

3

EN0B-0478GE51

R0105