CN0B-0341CH33 R0407

1

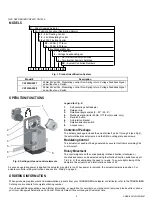

N20, N34 SERIES

NON-SPRING RETURN DAMPER ACTUATOR

20/34 Nm (177/300 lb-in) FOR MODULATING CONTROL

PRODUCT DATA

GENERAL

These direct-coupled damper actuators provide modulating

control for:

•

Air

dampers

•

VAV

units

•

Air

handlers

•

Ventilation

flaps

•

Louvers,

and

•

Reliable control for air damper applications with up to

4.6m

2

/ 50 sq.ft. (20 Nm / 177 lb-in) or 7.8m

2

/ 85 sq.

ft. (34 Nm / 300 lb-in)(seal- less damper blades; air

friction-dependent)

FEATURES

•

New self-centering shaft adapter

•

Access cover to facilitate connectivity

•

Declutch for manual adjustment

•

Mechanical end limits (CN7220 only)

•

Field-installable auxiliary switches

•

Rotation direction selectable by switch

•

Mountable in any orientation (no IP54 if upside down)

•

Mechanical position indicator

SPECIFICATIONS

Supply voltage

24 Vac ±20%, 50/60 Hz;

24 Vdc -10...+20%

Nominal voltage

24 Vac, 50/60 Hz; 24 Vdc

All values stated hereinafter apply to operation under

nominal voltage conditions.

Power consumption

CN7220 6 VA / 6 W

CN7234 8 VA / 6 W

Ambient limits

Ambient operating limits -20...+60

℃

(-5...+140 °F)

Ambient storage limits

-40...+80

℃

(-40...+175 °F)

Relative humidity 5...95%, non-condensing

Safety

Protection standard IP54 as per EN 60529

Protection class II as per EN 60730-1

Overvoltage category II

Lifetime

Full strokes 60000

Repositions

1.5 million

Mounting

Round damper shaft

10…27 mm (3/8...1-1/16”)

Square damper shaft 10...18 mm (3/8...11/16”)

45° steps

Shaft length

min. 22 mm (7/8”)

Control signal

0(2)...10 Vdc

0(4)...20 mA

Input impedance

100

k

Ω

[0...10 V]

500

Ω

m [0...20 mA]

Feedback signal

Limits ± 1 mA at 0...10 V

Torque rating

CN7220 20 Nm (177 lb-in)

CN7234 34 Nm (300 lb-in)

Runtime

95 sec (60 Hz) / 110 sec (50 Hz)

Rotation stroke

95°± 3°

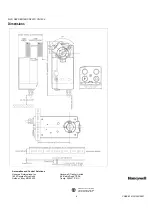

Dimensions

see “Dimensions” on page 6

Weight

1.35 kg (3 lbs.)

Noise rating

40 dB(A) max. at 1 m