SmartAct N20010, N34010

EN0B-0341GE51 R0307

2

MODELS

order number

supply voltage

end switches

control signal

feedback

torque

N20010

24 Vac

--

0...10 Vdc / 0...20 mA 0...10 Vdc 20 Nm (177 lb-in)

N20010-SW2

24 Vac

2

0...10 Vdc / 0...20 mA 0...10 Vdc 20 Nm (177 lb-in)

N34010

24 Vac

--

0...10 Vdc / 0...20 mA 0...10 Vdc 34 Nm (300 lb-in)

Product Identification System

SmartAct

N

3

2

0

2 0

X

N = non-spring return

S = spring return

20 = 20 Nm (177 lb-in)

34 = 34 Nm (300 lb-in)

010 = modulating

24 = 24 V fON/OFF

230 = 230 V fON/OFF

Fig. 1. Product Identification System

OPERATION / FUNCTIONS

2

3

4

5

6

7

8

30

60

60

90 90

0

30

0

1

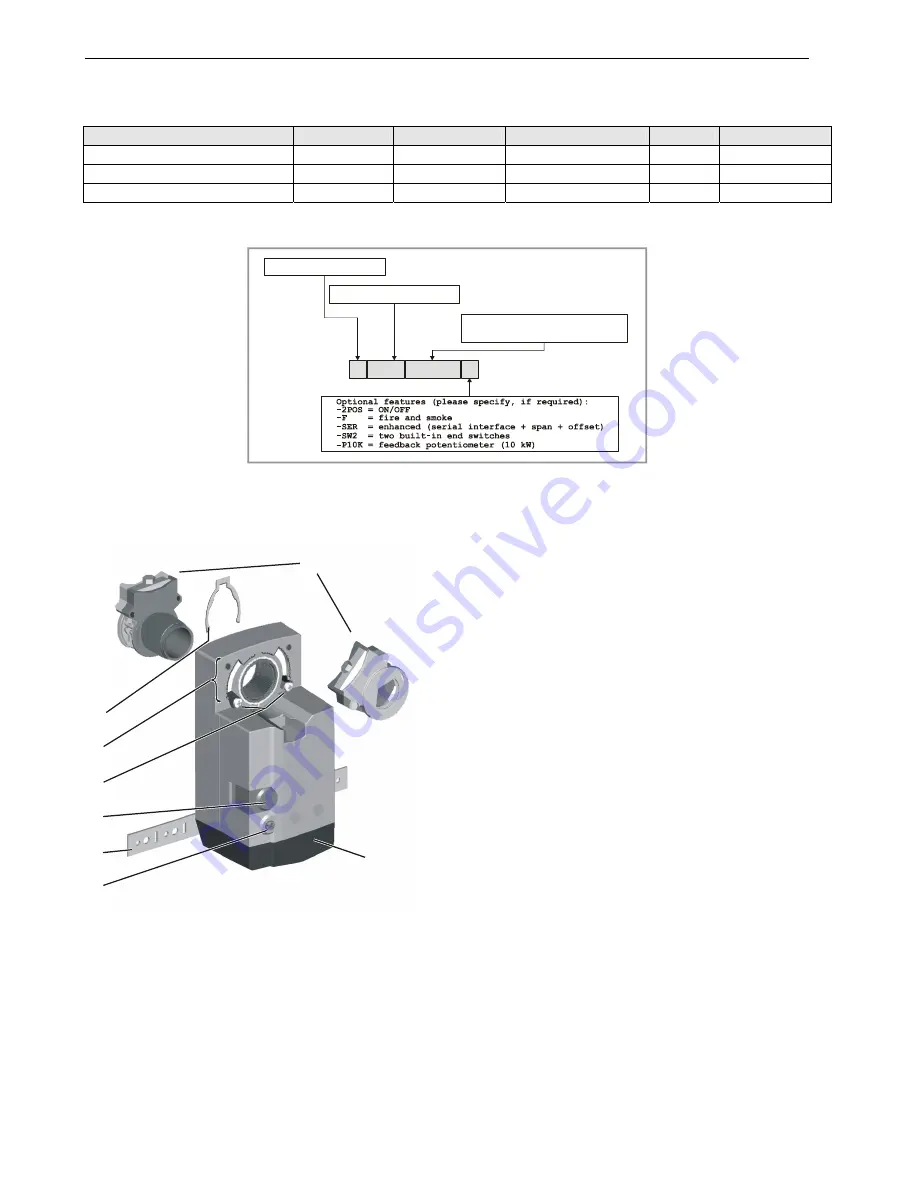

Fig. 2. Setting units and control elements

Legend for Fig. 2:

1

Self-centering shaft adapter

2 Retainer

clip

3

Rotational angle scales (0...90° / 90...0°)

4

Mechanical end limits (20 Nm [177 lb-in] models, only)

5 Declutch

button

6 Anti-rotation

bracket

7

Rotation direction switch

8 Access

cover

Contents of Package

The delivery package includes the actuator itself, parts 1

through 8 (see Fig. 2), the anti-rotation bracket screws, and

the SM mounting plate and screws.

Modulating Control

The actuator is capable of being operated by several

controllers providing Vdc or mA output.

Rotary Movement

The control signal and the corresponding rotation direction

(clockwise or counterclockwise) can be selected using the

rotation direction switch (see part 7 in Fig. 2), thus eliminating

the need to re-wire. To ensure tight closing of the dampers,

the actuator has a total rotation stroke of 95°.

As soon as operating power is applied, the actuator may start

to run. When power is removed, the actuator remains in

position. For actuator-controller wiring instructions, see

section "Wiring" on page 5.