SmartAct N20010, N34010

3

EN0B-0341GE51

R0307

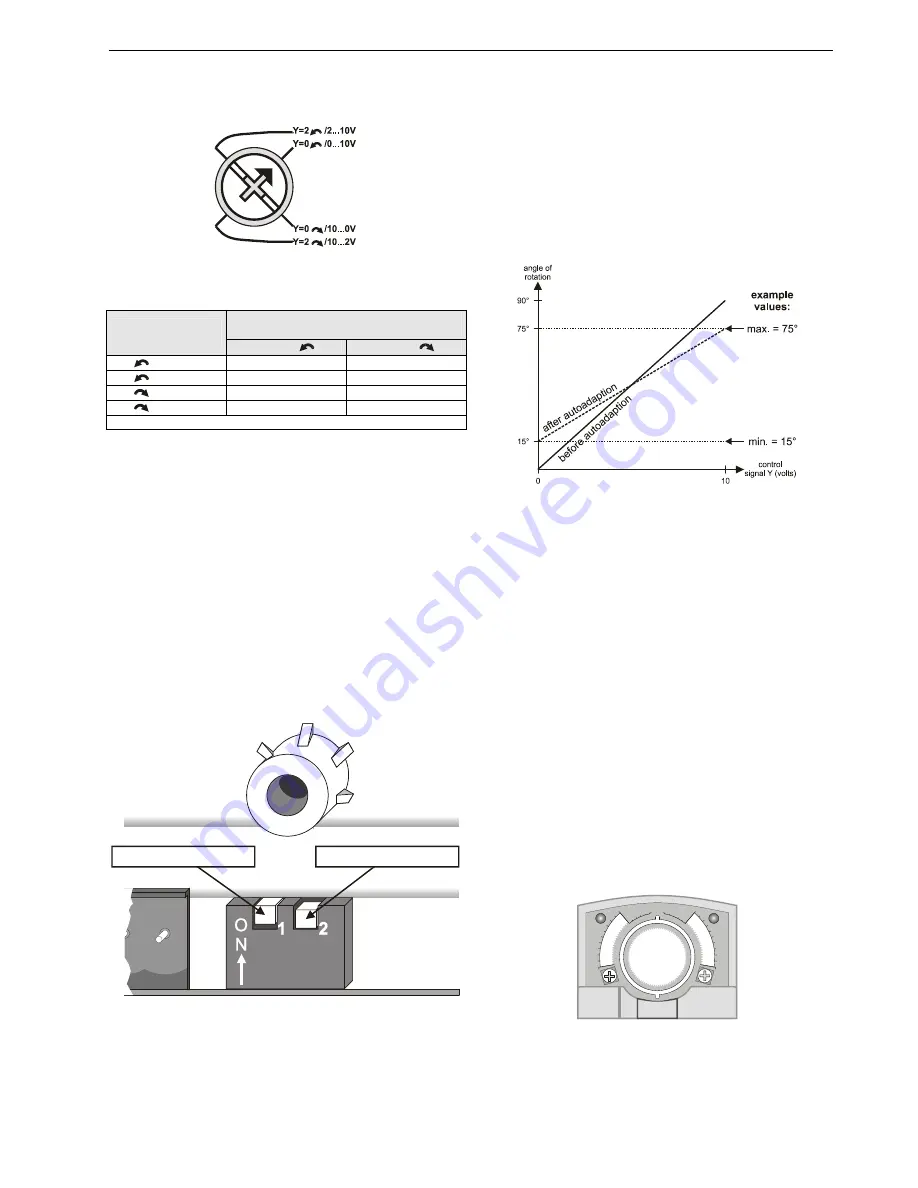

Rotation Direction Switch

Fig. 3. Rotation Direction Switch

Table 1. Feedback/control signal values

feedback/control signal when

actuator is

rotation direction

switch position

totally

totally

Y=2

/2...10V

U = 2 V

U = 10 V

Y=0

/0...10V*

U = 0 V

U = 10 V

Y=0

/10...0V

U = 10 V

U = 0 V

Y=2

/10...2V

U = 10 V

U = 2 V

* Default shipping position.

Feedback Signal and Manual Adjustment

If, while the actuator is not rotating, the user declutches it and

manually repositions the shaft adapter, the feedback signal

will then follow the new position at which the shaft adapter

has been left.

Power OFF/ON Behavior

In case the power to the actuator fails, after re-applying

power, the actuator aknowledges its present position and

follows the signal from the controller. This makes it

unnecessary for the actuator to employ autoadaption in order

to re-map the control signal settings.

Dip Switches

The actuators are equipped with two dip switches accessible

after removing the access cover (see Fig. 4).

voltage/current control signal

dip switch (

)

OFF

autoadapt dip switch for

normal operation (

)

ON

Fig. 4. Dip switches (view with PCB at bottom)

Autoadapt Dip Switch for Normal Operation

In its default shipping position, the autoadapt dip switch for

normal operation is set to

ON

as shown in Fig. 4. If it is set to

OFF, no autoadapting is performed, and the control signal

map remains constant.

The autoadapt functionality does not have to be triggered.

Rather, the SmartAct actuator does this automatically when

the min. and max. control signals are provided (see Fig. 5);

the feedback signal is likewise autoadapted.

Fig. 5. Actuator positioning curve

Adjusting the Actuator for Autoadapt

In order to make use of the autoadapt functionality, proceed

as follows:

1. Set the autoadapt dip switch to the ON position.

2. If necessary, limit the stroke to the desired range using

the mechanical end limits.

3. Drive the actuator to the left end limit (totally counter-

clockwise) by setting the control signal as specified in

Table 1.

4. Drive the actuator to the right end limit (totally clockwise)

by setting the control signal as specified in Table 1. The

stroke has now been limited to 0...100% of the control

signal range.

Voltage/Current Control Signal Selection Dip Switch

In its default shipping position, the voltage/current control

signal dip switch (see Fig. 4) is set to

OFF

(= voltage control).

as shown in Fig. 4. Setting it to ON results in current control.

Position Indication

The hub adapter indicates the rotation angle position by

means of the rotational angle scales (0...90° / 90...0°).

90 90

60

30

60

30

0

0

Fig. 6. Position indication