Installing the Network Gateway Unit

(Continued)

3

X

X

D

D

A

A

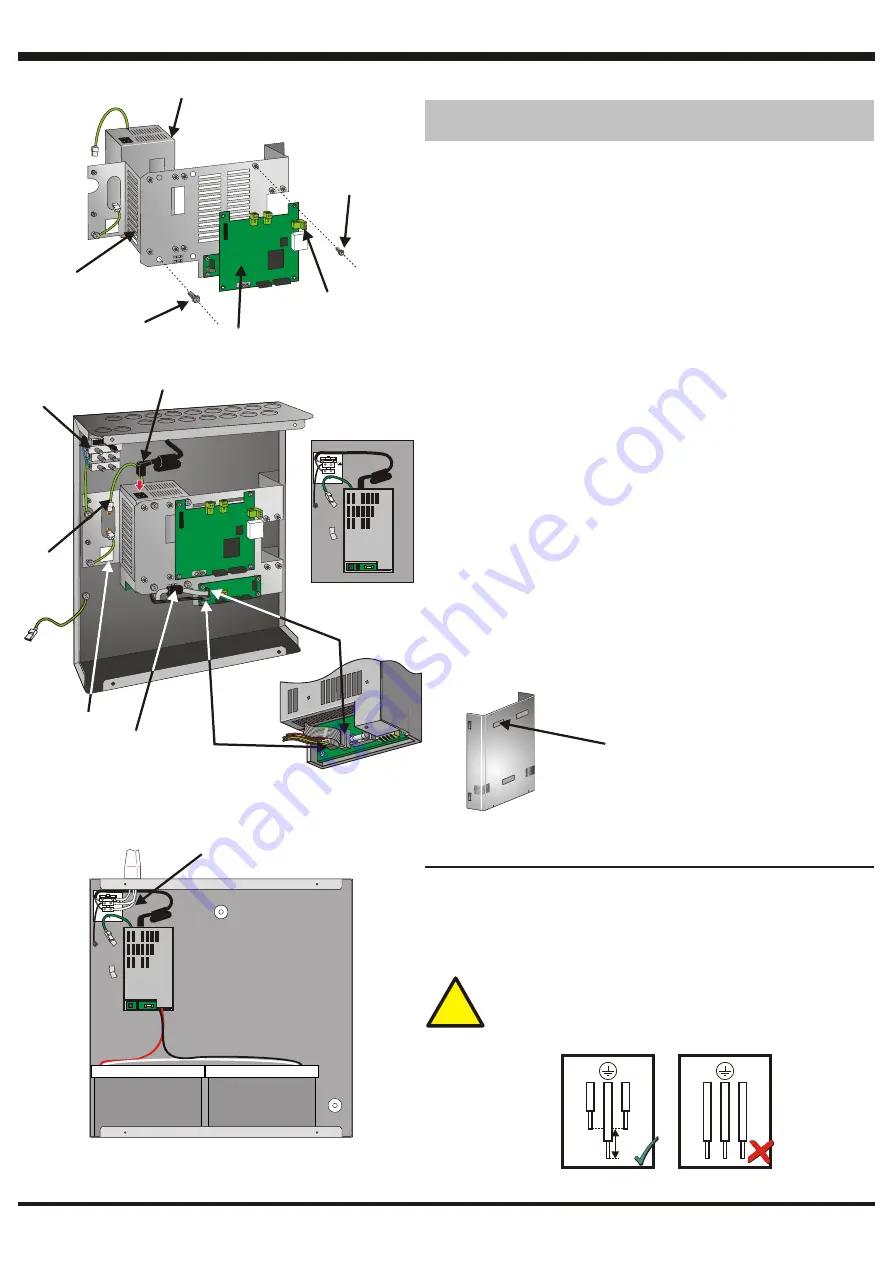

Fitting a PSU3A (Kit PN: 020-648) - Optional

This procedure assumes that the chassis has been removed from the back

box - see ‘Preparing the Back Box’.

1

Disconnect the dc connector (A) from the Network Gateway Module

(NGM) - (B).

2

Remove and retain the four M3 X 8 SEM screws (C) that secure the NGM

to the chassis, then remove the NGM and store it safely (take anti-static

precautions).

3

Orientate the PSU3A (D) as shown and secure it to the chassis using the

M4 x 8 SEM screws (E) supplied with the PSU3A.

4

Replace the NGM onto the chassis (by reversing steps 2 and 1 above),

then replace the chassis in the back box.

Ensure the chassis earth

connection is remade.

5

Push the connector of the PSU3A mains cable (F) into the socket on the

PSU3A [the other end of the mains cable is factory-fitted to the mains

terminal block (G)]. Ensure the mains cable is routed as shown in the

illustration. Pull tight the cable clip at the side of the back box.

6

Connect the PSU earth lead (H) to the upper blade on the back box.

7

Connect the 4-way power cable (I) and 10-way ribbon cable (J) (supplied

with the NGU) between the PSU3A and the PSU3A to Network Interface

PCB.

8

Use the supplied cable tie to secure the ribbon cable’s ferrite (K) to the tie

point on the chassis.

9

Remove and discard the PSU rating label (L) from the chassis.

10

Remove and discard the NGU product label (M) from the cover. Peel off

the backing from the NGU EN54-compliant label supplied in the NGU

accessory kit, and attach the label to the cover in place of the removed

label.

Fitting a PSU3A (Kit PN: 020-648) - Optional

This procedure assumes that the chassis has been removed from the back

box - see ‘Preparing the Back Box’.

Disconnect the dc connector (A) from the Network Gateway Module

(NGM) - (B).

Remove and retain the four M3 X 8 SEM screws (C) that secure the NGM

to the chassis, then remove the NGM and store it safely (take anti-static

precautions).

Orientate the PSU3A (D) as shown and secure it to the chassis using the

M4 x 8 SEM screws (E) supplied with the PSU3A.

Replace the NGM onto the chassis (by reversing steps 2 and 1 above),

then replace the chassis in the back box.

Push the connector of the PSU3A mains cable (F) into the socket on the

PSU3A [the other end of the mains cable is factory-fitted to the mains

terminal block (G)]. Ensure the mains cable is routed as shown in the

illustration. Pull tight the cable clip at the side of the back box.

Connect the PSU earth lead (H) to the upper blade on the back box.

Connect the 4-way power cable (I) and 10-way ribbon cable (J) (supplied

with the NGU) between the PSU3A and the PSU3A to Network Interface

PCB.

Use the supplied cable tie to secure the ribbon cable’s ferrite (K) to the tie

point on the chassis.

Remove and discard the PSU rating label (L) from the chassis.

Remove and discard the NGU product label (M) from the cover. Peel off

the backing from the NGU EN54-compliant label supplied in the NGU

accessory kit, and attach the label to the cover in place of the removed

label.

1

2

3

4

Ensure the chassis earth

connection is remade.

5

6

7

8

9

10

TRANSIT CABLE CLIP: Before proceeding, CAREFULLY cut the cable

clip that secures the ferrite cable loop to the chassis (at 'X' on drawing).

TRANSIT CABLE CLIP: Before proceeding, CAREFULLY cut the cable

clip that secures the ferrite cable loop to the chassis (at 'X' on drawing).

B

B

C

(typical 4

locations)

C

(typical 4

locations)

E

(typical 4

locations)

E

(typical 4

locations)

G

G

F

F

NN

LL

F - in detail

F - in detail

H

H

II

J

J

K

K

PSU3A

PSU3A

Wiring Connections - Mains and Safety Earth

Live and Neutral must only be connected if the PSU3A is fitted.

The earth

connection must always be connected.

Cables are to be brought into the

back box using 20mm knockouts and appropriate glands - (refer to the panel’s

Installation & Commissioning manual) in accordance with local standards.

Terminate the mains/earth at the terminal block; connections are labelled.

Live and Neutral must only be connected if the PSU3A is fitted.

The earth

connection must always be connected.

Cables are to be brought into the

back box using 20mm knockouts and appropriate glands - (refer to the panel’s

Installation & Commissioning manual) in accordance with local standards.

Terminate the mains/earth at the terminal block; connections are labelled.

!!

Segregate mains wiring from all other wiring.

When terminating mains leads, ensure that the earth lead is

longer than L and N.

Segregate mains wiring from all other wiring.

When terminating mains leads, ensure that the earth lead is

longer than L and N.

>25mm

L

N

L

N

L

L

M

M

997-451, Issue 6 July 2006

NN

LL

FOR CLARITY, SHOWN WITH

CHASSIS REMOVED

FOR CLARITY, SHOWN WITH

CHASSIS REMOVED

MAINS

WIRES

MAINS

WIRES