Installing the Network Gateway Unit

(Continued)

4

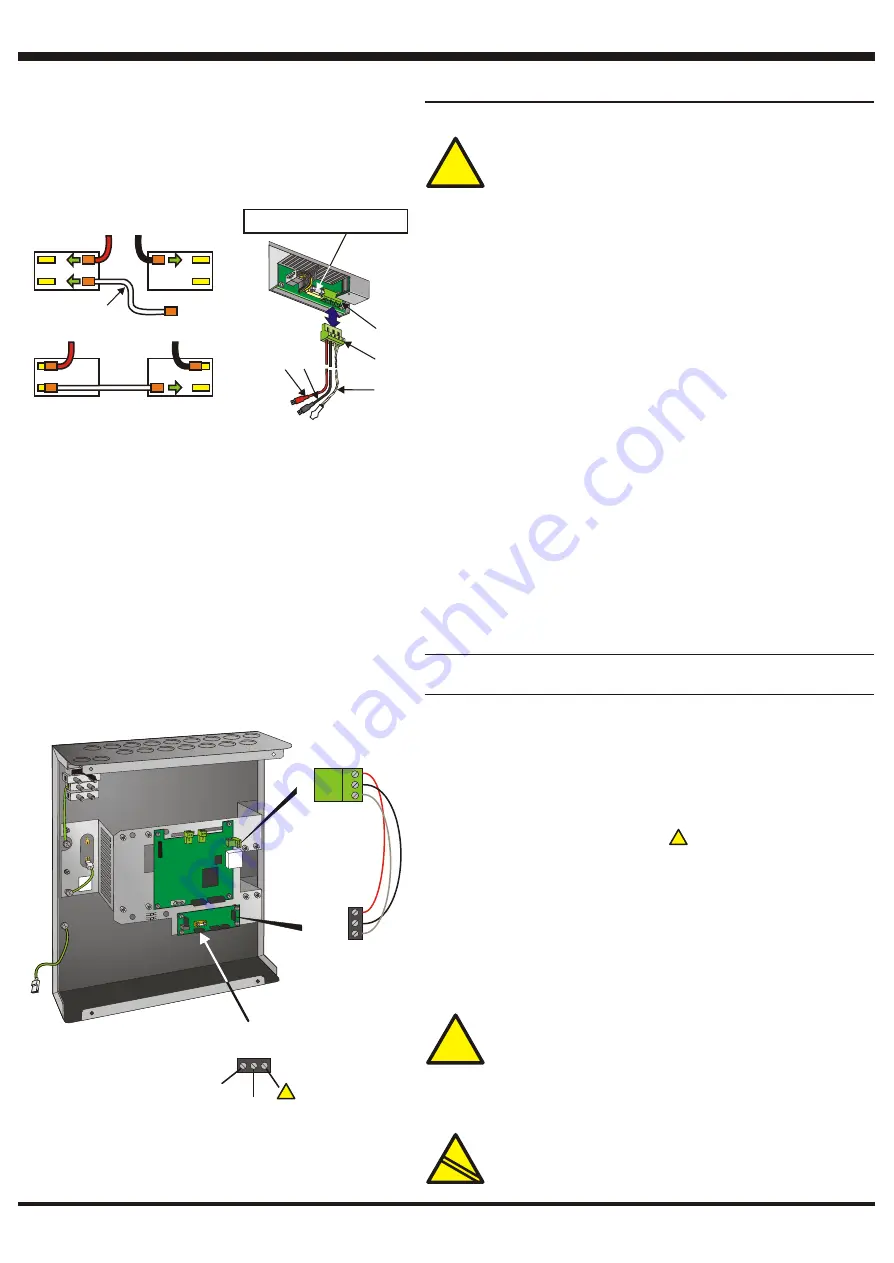

Wiring Connections - Batteries

Use valve-regulated, lead-acid type12V, 12Ah batteries.

1

Externally isolate the mains supply at the third-party-supplied isolation

unit.

2

Connect the battery supply wiring plug (A) to the power socket (B).

3

Place the batteries temporarily in position (with their terminals outermost)

and measure from the PSU’s 4-way output socket to the rear terminal of

each battery (i.e. one positive and one negative). Disconnect the leads

from the output socket. Cut the battery leads supplied to length. Measure

from the socket to a position on the side wall - NOT the top plate - of the

right-hand battery and cut the thermistor lead to length. In both cases

make the leads as short as possible. Reconnect the leads to the socket.

Remove the batteries from the back box.

4

Connect the red wire (C) to the positive terminal of battery 2 and the black

wire (D) to the negative terminal on battery 1.

5

Fit the batteries in the back box. Use a suitable silicon-based sealant to

secure the thermistor (E) to the side wall - NOT the top plate - of the right

hand battery.

6

Connect the interlink cable (F) between battery 1 positive and battery 2

negative terminal. This will power up the NGU, so do this AFTER wiring to

the PCBs has been connected (see following pages).

7

When all wiring connections have been completed, fit the cover to the

back box (ensure the interlink cable is not squashed), and then apply

power.

Use valve-regulated, lead-acid type12V, 12Ah batteries.

1

2

3

4

5

6

7

Externally isolate the mains supply at the third-party-supplied isolation

unit.

Connect the battery supply wiring plug (A) to the power socket (B).

Place the batteries temporarily in position (with their terminals outermost)

and measure from the PSU’s 4-way output socket to the rear terminal of

each battery (i.e. one positive and one negative). Disconnect the leads

from the output socket. Cut the battery leads supplied to length. Measure

from the socket to a position on the side wall - NOT the top plate - of the

right-hand battery and cut the thermistor lead to length. In both cases

make the leads as short as possible. Reconnect the leads to the socket.

Remove the batteries from the back box.

Connect the red wire (C) to the positive terminal of battery 2 and the black

wire (D) to the negative terminal on battery 1.

Fit the batteries in the back box. Use a suitable silicon-based sealant to

secure the thermistor (E) to the side wall - NOT the top plate - of the right

hand battery.

Connect the interlink cable (F) between battery 1 positive and battery 2

negative terminal. This will power up the NGU, so do this AFTER wiring to

the PCBs has been connected (see following pages).

When all wiring connections have been completed, fit the cover to the

back box (ensure the interlink cable is not squashed), and then apply

power.

!!

CAUTION - ENERGY HAZARD! NEVER short the battery

terminals.

CAUTION - ENERGY HAZARD! NEVER short the battery

terminals.

This procedure only applies if the PSU3A is fitted.

This procedure only applies if the PSU3A is fitted.

Using an External 28V dc Power Supply - Optional

The external dc power supply must satisfy the ratings given in the section

‘NGU Electrical Specifications’.

The mains block earth connection must

still be connected to earth

- see ‘Wiring Connections - Mains and Safety

Earth’ on the previous page.

1

Bring the 28V dc cable into the back box via a 20mm knockout. Route the

cable behind the chassis, as close as possible to the rear wall of the back

box.

Never route the cable across the front of the NGM.

2

Connect the dc supply to the 0V and

terminals of the 28V connector

2

TB2 on the PSU3A to Network Interface PCB. The use of 1.5mm cable is

recommended. See EMC requirements warning below.

3

Remove the white wire (PSU FAULT) between the PSU3A to Network

Interface PCB 5V connector TB1 and the NGM 5V connector. Connect the

fault output from the external supply to the removed connection at the

NGM. (Open circuit = fault, Short circuit to 0V = OK). If the external supply

does not have a fault output, jumper between this removed connection

and the black wire (0V) at the NGM.

__

Using an External 28V dc Power Supply - Optional

The external dc power supply must satisfy the ratings given in the section

‘NGU Electrical Specifications’.

- see ‘Wiring Connections - Mains and Safety

Earth’ on the previous page.

Bring the 28V dc cable into the back box via a 20mm knockout. Route the

cable behind the chassis, as close as possible to the rear wall of the back

box.

Connect the dc supply to the 0V and

terminals of the 28V connector

TB2 on the PSU3A to Network Interface PCB. The use of 1.5mm cable is

recommended. See EMC requirements warning below.

Remove the white wire (PSU FAULT) between the PSU3A to Network

Interface PCB 5V connector TB1 and the NGM 5V connector. Connect the

fault output from the external supply to the removed connection at the

NGM. (Open circuit = fault, Short circuit to 0V = OK). If the external supply

does not have a fault output, jumper between this removed connection

and the black wire (0V) at the NGM.

The mains block earth connection must

still be connected to earth

1

Never route the cable across the front of the NGM.

2

3

__

2

!!

28V DC

CONNECTOR

28V DC

CONNECTOR

5V DC

CONNECTOR

AT NGM

5V DC

CONNECTOR

AT NGM

5V DC

CONNECTOR

AT I/F BOARD

5V DC

CONNECTOR

AT I/F BOARD

RED

RED

BLACK

BLACK

WHITE

WHITE

RED

RED

BLACK

BLACK

WHITE

WHITE

!!

0V

0V

NO

CONNECTION

NO

CONNECTION

!!

EMC requirements: a ferrite (supplied with the NGU) is

required for the dc power input cable and for the fault signal

cable. Fit the ferrite directly under the gland at the back box

knockout. The screen (if plastic glands are used) and all

cores (plastic or metal glands) of the cable must pass

through the ferrite.

EMC requirements: a ferrite (supplied with the NGU) is

required for the dc power input cable and for the fault signal

cable. Fit the ferrite directly under the gland at the back box

knockout. The screen (if plastic glands are used) and all

cores (plastic or metal glands) of the cable must pass

through the ferrite.

EN54

!

EN54

!

Use of an external dc power supply does not comply with

EN54 Part 4.

Use of an external dc power supply does not comply with

EN54 Part 4.

THE

RM

THE

RM

+

-

+

-

A

A

E

E

C

C D

D

Fuse FP2 T 6.3A H 250V

Fuse FP2 T 6.3A H 250V

B

B

997-451, Issue 6 July 2006

+

-

+

+

-

Battery 1

Battery 1

Battery 2

Battery 2

F

F

C

C

D

D