P520 SIGNAL PROCESSOR

66-2066—01

10

TROUBLESHOOTING

Module Communications

The P520 communicates with any host computer that has a

USB port and supports ASCII character code transmission at

4800 baud (or, in current revisions of the processor chip, at

4800 or 9600 baud). The baud rate is displayed with the

module address in the current versions (see SETTING

ADDRESSES, section). The data transmitted to and from the

P520 is over two twisted pairs that are differentially driven and

received according to the RS-422 standard. The differential

mode allows long wire runs in harsh, electrical environments.

Honeywell offers a RS485/422 to USB converter to use in

conjunction with the P520 signal processor. The Honeywell

part number is COMMOD.

Modbus Communication protocol allows the P520 to

communicate with open process controllers or human-

interface host computers that support this protocol. The P520

processor status and settings are organized as 23 4X holding

registers and five 0X discrete registers. For more information

on Modbus protocol, please refer to Modicon’s Modbus

Protocol Reference Guide (PI-MBUS-300 Rev E).

Communication Setting

P520 can communicate only in Modbus RTU mode, with the

following configuration:

• 9600 baud

• 8 data bits

• No parity

• 1 stop bit

The factory default of a P520 station number is 0. It is

important to change the station number so that there are no

duplicate stations in the network.

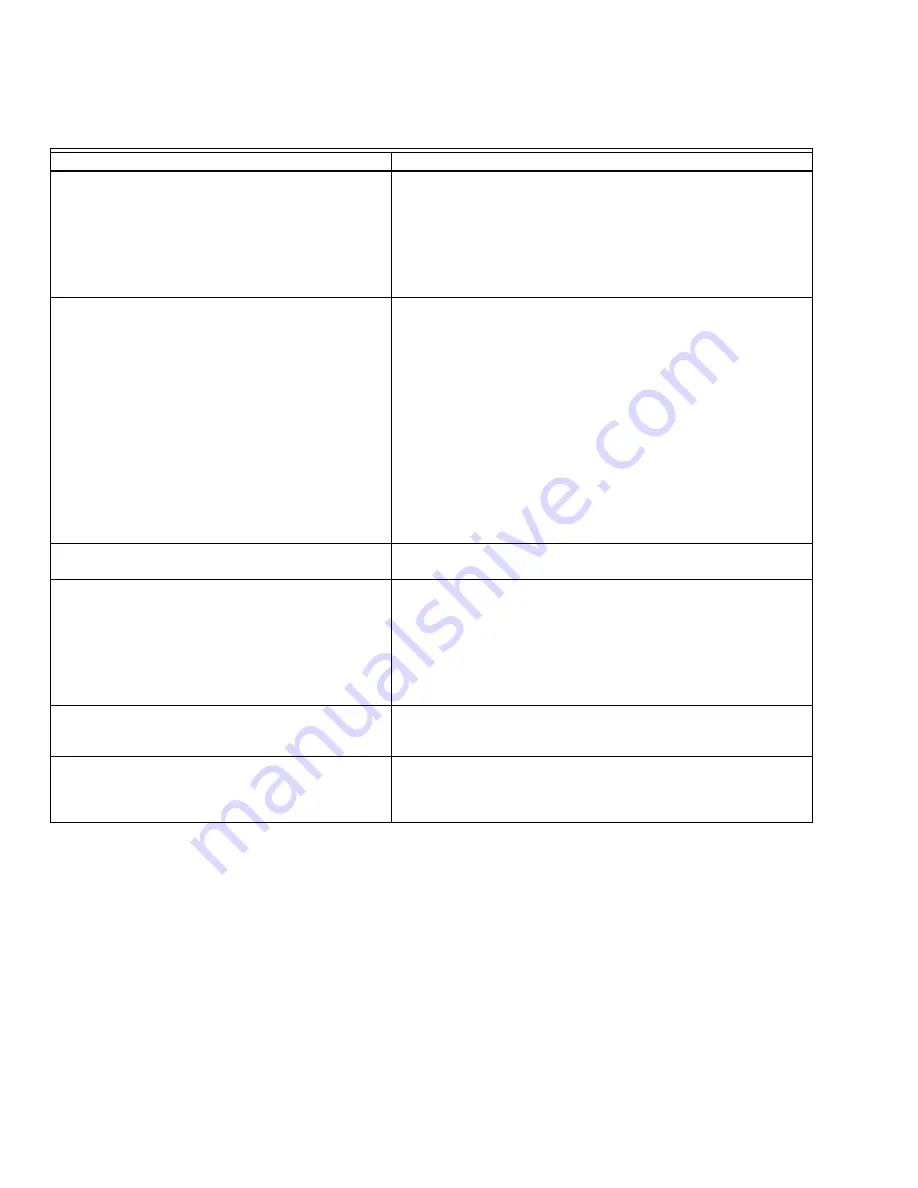

Table 5. Troubleshooting procedures.

Problem

Troubleshooting Steps

No flame signal and no display.

1.

Check the wiring between the signal processor and the viewing

head. Refer to the Wiring the Rear PC Board section.

2.

Using a volt meter check the voltage at PWR IN terminals with a

volt meter. It should measure approximately 24VDC. If not,

check the power supply and wiring, or replace the power supply.

3.

If 24VDC is measured, remove the power for 10 seconds. If the

self-resetting fuse has tripped, removing then reapplying power

will reset the fuse.

Digital display shows 0000 and there is no flame signal.

1.

Remove connector from viewing head and check wiring per

2.

Ensure the proper impedance resistor is in place (refer to Wiring

of Viewing Head section). Using a volt meter, check the viewing

head terminals on the P520, for 24VDC V and GND. If

the voltage is low, check input voltage to the signal processor. If

the input voltage is measured to be in spec, remove power and

disconnect all connections to the viewing head(s). Wait 10 sec-

onds (which resets the self-resetting fuse) and then reapply

power and re-measure voltage V and GND.

3.

If voltage me24VDC (nominal) at the viewing head ter-

minals at the signal processor, turn off power to the signal pro-

cessor and using an ohmmeter check continuity of each cable

wire from the signal processor terminals to the viewing head

connector terminals. If cable continuity checks out, the viewing

head may be defective.

Flame signal shows on display; flame on relay and light

are off.

1.

The viewing head is incorrectly wired, or defective (see above).

2.

The set point values for flame ON are incorrect.

Flame signal shows on analog bar graph display; flame

light is off; lockout light is on.

1.

The viewing head may be defective.

2.

There may be a noise or grounding problem. Check that equip-

ment is properly grounded and ensure good clean contact on all

ground connections. Move viewing head and cable/conduit at

least 12 inches (31 cm) away from any source of high powered

switching (e.g. igniter equipment). Refer to Grounding and

Shielding section.

3.

Press the RESET button on the front panel.

The 1-9 LED stays on.

1.

There may be a noise or grounding problem (see above and

refer to Grounding and Shielding section).).

2.

The viewing head may be defective.

The front panel buttons do not respond.

1.

The P520 front panel may be locked out.

2.

Signal processor may be in remote operation only mode.

3.

Cycle power to the signal processor with the viewing head con-

nected.