18

12 Technical data

Mains voltage/frequency 230 V AC ± 10% / 50/60 Hz

Rated wattage

2.5 watts

Display

3-digit, 7-segment, red LED, 14.2 mm

Resolution

1 K

Measuring range

–55 to +50 °C

Outputs

1 relay with changeover contact, 8 A,

230 V AC, resistive load, (cooling).

1 relay with N.O. contact, 8 A

(5A PCR-300RC), 230 V AC,

resistive load, (defrost heating).

1 relay with N.O. contact, 8 A (5A -PCR-300RC),

230 V AC, resistive load (fan control).

Control response

Two-step

Alarm output

Opto bidirectional triode thyristor, 250 V AC,

max. load 80mA

Display accuracy

± 0.5K internal, ± 1 digit, at 25 °C

Operating conditions

0 °C to 50 °C, 30 to 85 % R.H., excluding dew

Storage temperature

–20 °C to +80 °C

Data back-up

Non-volatile memory (EEPROM)

Clock: Back-up battery, approx. 1 month

power reserve (PCR-300 RC only)

Emergency setpoint

DIP switch under display cover

selection

(off = +4 °C / on = –18 °C)

Sensor type

PTC

– Number

2 sensors

T1 = Control signal to compressor relay

T2 = Control signal to defrost limitation and

fan control

– Cable length

2.5 m

– Range where cable

–30 °C to +80 °C not fixed

can be used:

–40 °C to +80 °C fixed

– Accuracy

± 2 %

Housing

L x W x H = 85 x 70 x 61 mm,

ABS plastic, self-extinguishing (UL 94 V0)

Protective rating

Housing: IP 20, front panel: IP 52

Class of protection 2

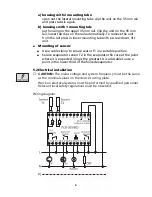

Terminals

250V / 10 A screw-type terminal strips,

with wire protection,

tightening torque 0.6 Nm

Max. core cross section 1.5 mm

2

Weight

Approx. 420 g (inc. 2 sensors).

Only operate the unit in dry places.

Errors in the technical data are excepted. We reserve the right to make changes without prior notice.