POL-200-TS User Manual

21

5. Troubleshooting

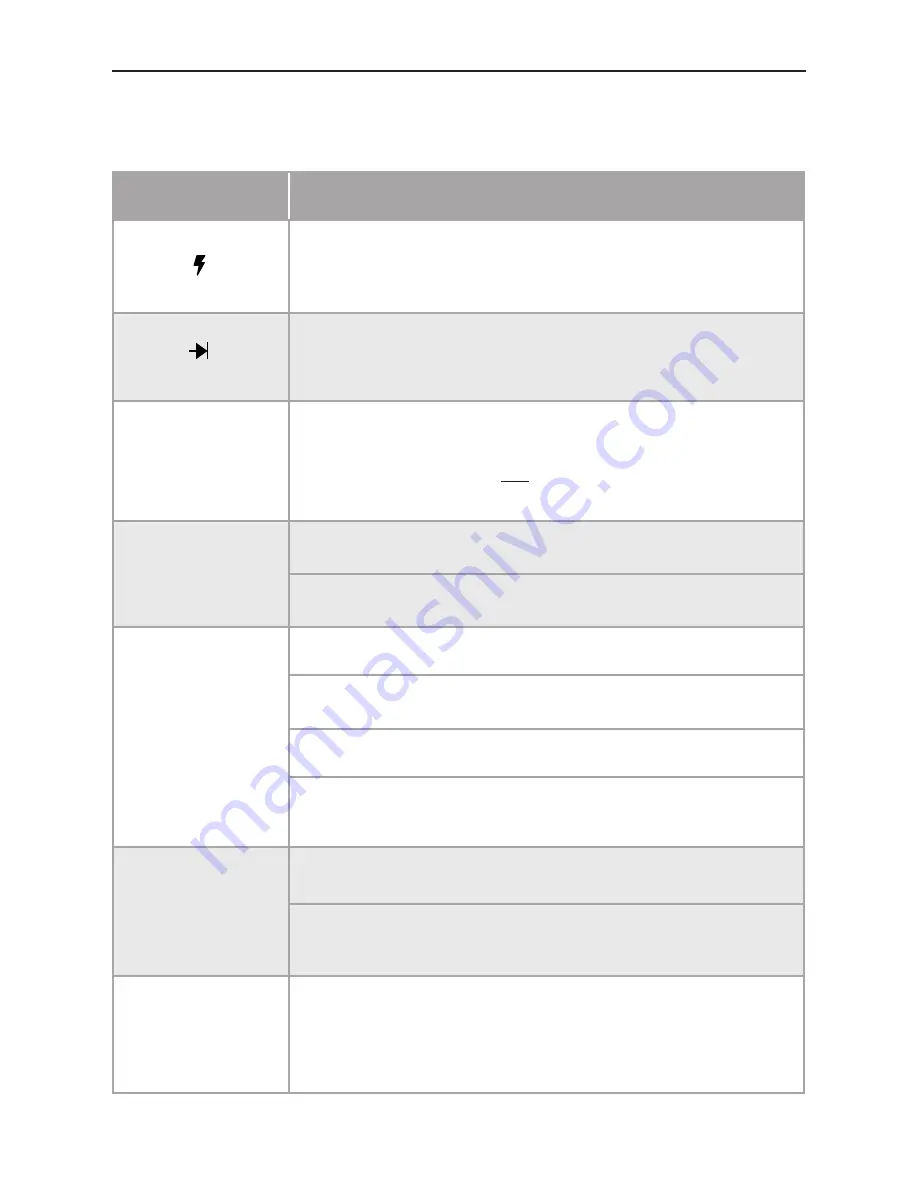

MESSAGE/

PROBLEM

CAUSE/SOLUTION

If this symbol appears in the right low corner, a short-circuit between loop positive and

negative is monitored. Please break the loop into sections to identify where the short-cir-

cuit is.

This symbol indicates an inverse wiring fault. Please break the loop into sections to identify

where the loop negative is incorrectly connected to the loop positive, or vice versa.

“h”… lower case:

If in the auto-learn ALL the devices in the loop appear with a lower case letter, please check

the protocol selected in the Configuration. It may be that the selected loop protocol, i.e.

Morley, System Sensor or Honeywell HBS, does not match the loop devices.

The screen flashes or it

switches off:

Check if the battery loading level is adequate.

The batteries may be damaged, replace them.

The device tags disappear

or the question character

appears:

Check that the loop conditions meet Honeywell requirements.

Try replacing the device and check again.

Check for possible noise on the line.

Record the information and check the possibility of cycles that are not carried out correctly,

of excessive current, etc.

No devices appear:

Check that you have not selected Advanced protocol instead of CLIP protocol

Check that the loop is connected to the input, “IN” of the POL-200-TS device.

There is no data recorded in

my * .MNA, * .MNC and / or

* .DAT files:

Remove or delete old files, they take up the available memory space.