5

60-2150—10

L404A-D,F; L604A,L,M

INSTALLATION

Installation

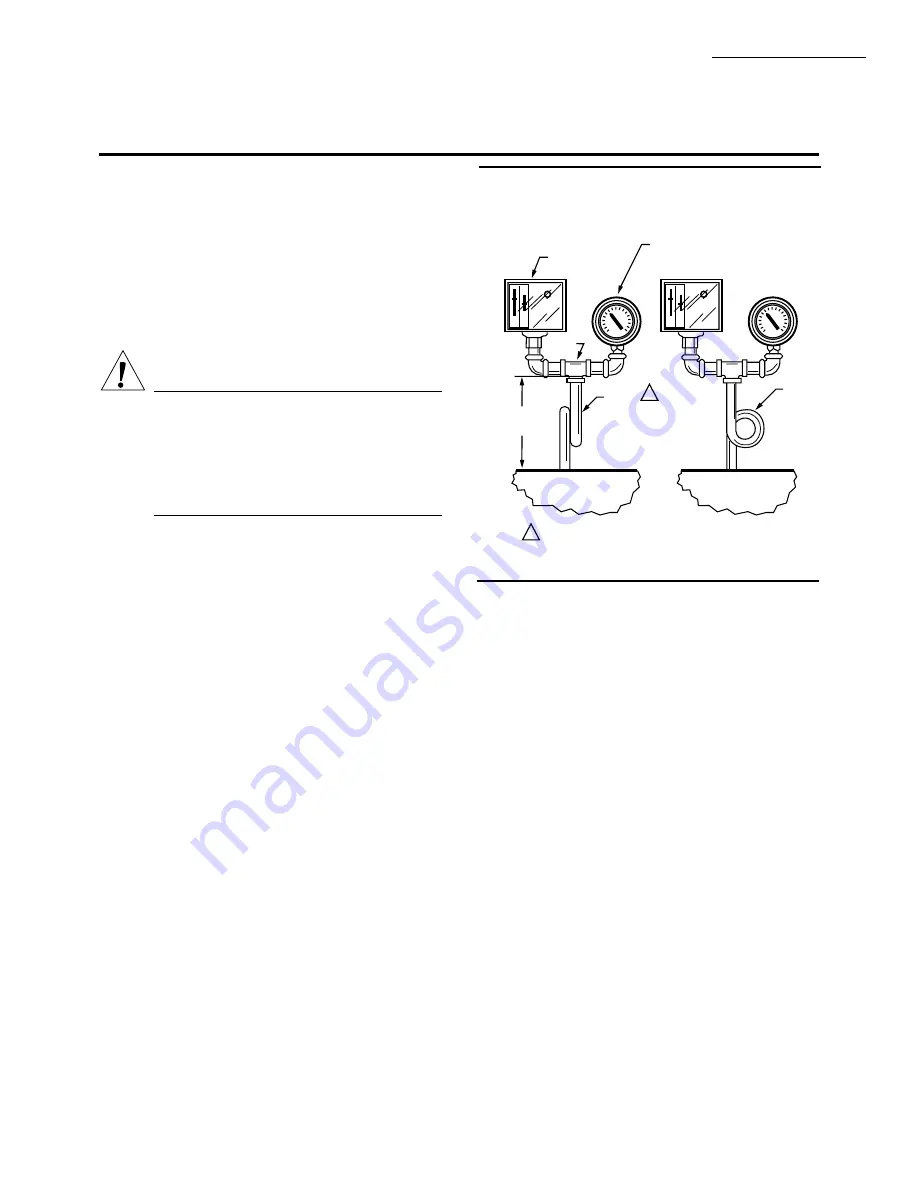

Fig. 2—Right and wrong mounting of a steam

trap (siphon loop), with approximate dimen-

sions in in. (mm).

4-1/2 TO 5-1/2

(114.3 TO 139.7)

BOILER

14026

STEAM TRAP

(SIPHON LOOP)

TEE

PRESSURE

GAUGE

PRESSUR

CONTROLLER

M8934

1

1

1/4 IN. BLACK IRON PIPE WITH 1/4 - 18 NPT EXTERNAL

TRHEADS ON BOTH ENDS. BEND THE STEAM TRAP

(SIPHON LOOP) TO LEVEL THE CONTROLLER.

CORRECT

BOILER

2-1/4

(57.2)

DIA.

INCORRECT

Make all pipe connections in accordance with approved

standards. Use only a small amount of pipe compound to

seal the connection joints. Excess pipe compound can clog

the small hole in the fitting and prevent the controller from

operating properly.

To avoid leaks and damage to the case, use a parallel jaw

wrench on the controller’s hexagonal fitting. Do not tighten

the controller by hand by holding the case.

Leveling

A controller with a mercury switch must be accurately

leveled for proper operation. It is level when the leveling

indicator (Fig. 11) hangs freely with its pointer directly

over the index mark inside the back of the case. Level the

controller by carefully bending the steam trap (siphon

loop).

Mounting Alongside a Pressure Gauge

To mount the controller alongside a pressure gauge

(Fig. 2), remove the gauge. In its place, install a steam trap

(siphon loop) with a tee on top. Using elbows and pipe

nipples, mount the controller and pressure gauge on the

ends of the tee. Level the controller after installation.

WHEN INSTALLING THIS PRODUCT. . .

1. Read these instructions carefully. Failure to follow

them could damage the product or cause a hazardous

condition.

2. Check the ratings given in the instructions and on the

product to make sure the product is suitable for your

application.

3. Installer must be a trained, experienced, flame safe-

guard control technician.

4. After installation is complete, check out product

operation as provided in these instructions.

CAUTION

1. Disconnect power supply before beginning in-

stallation to prevent possible equipment dam-

age or electrical shock.

2. When using the controller with a compressor,

install a dampening device (such as a needle valve,

header, or surge tank) to dampen pulsations that

can damage the controller or reduce its life.

IMPORTANT:

1. Locate the controller where the ambient temperature

will not exceed 150

!

F (66

!

C).

2. Use pipe compound sparingly to avoid clogging the

hole in the pipe or diaphragm fitting.

3. Do not tighten the controller by hand by holding the case.

4. Accurately level the controller for proper operation.

LOCATION AND MOUNTING

NOTE: For most accurate operation; add supplemental heat

to installations where the temperature falls below minus

20

!

F (minus 29

!

C). Never locate the controller where the

temperature falls below minus 35

!

F (minus 37

!

C), be-

cause mercury in the switch freezes at this temperature.

When used with steam boilers, always mount the con-

troller above the water line in the boiler. A steam trap

(siphon loop) must always be connected between the con-

troller and the boiler (Fig. 2) to prevent boiler scale and

corrosive vapors from attacking the diaphragm. The loop

on the steam trap must always be perpendicular to the face

of the controller. If the loop is parallel to the controller,

expansion or contraction of the loop tips the controller and

causes the switch to operate inaccurately.

The controller can be mounted (1) alongside the pres-

sure gauge, (2) in a fitting on the boiler provided by the

manufacturer, (3) at a remote location in case of excessive

vibration, or (4) in a special mounting on a low water

cutoff.

Summary of Contents for Pressuretrol L404 Series

Page 11: ...11 60 2150 10 ...