L404F,T,V PRESSURETROL

®

CONTROLLERS

3

71-2429—06

Table 2. Conversion Table.

Table 3. Switch Ratings (Amperes).

Pressure Sensing Element:

Stainless steel diaphragm (140

to 2070 kPa models) has brass bellows.

Maximum Ambient Temperature:

66°C (150°F). Also, refer

to note under Mounting.

Adjustment Means:

Screws on top of control case. Scales are

marked in psi or kPa.

Mounting Means:

1/4 inch-18 NPT connection on diaphragm

assembly; or surface mounts using holes in back of case.

Dimensions:

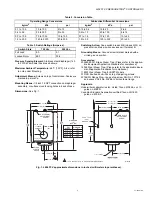

See Fig. 1.

Switching Action:

Snap switch breaks R-B (closes R-W) on

pressure rise. Make-on-rise devices omit terminal B.

Grounding Means:

Ground screw terminal marked with a

circled ground symbol.

Accessories:

50024585-001 Brass Steam Trap. (Please refer to the applica-

ble Equipment/Application Standards for compliance.)

14026 Steel Steam Trap. (Please refer to the applicable Equip-

ment/Application Standards for compliance.)

118023 Steel Steam Trap for BSPT Models.

33312B Knurled Knob—fits on top of adjusting screws.

4074BWJ Range Stop—range stop screw, Part No. 107194,

and wrench, Part No. 23466, to limit setpoint range.

Approvals:

Underwriters Laboratories Inc. Listed: file no. MP466, vol. 10,

guide no. MBPR.

Canadian Standard Association certified: file no. LR1620,

guide no. 400E-0.

Fig. 1. L404F,T,V approximate dimensions in inches (millimeters in parentheses).

Operating Range Conversions

Subtractive Differential Conversions

kg/cm

2

kPa

psi

kg/cm

2

kPa

psi

0.1 to 1.05

15 to 100

2 to 15

0.15 to 0.4

15 to 40

2 to 6

0.4 to 3.5

35 to 350

5 to 50

0.4 to 1.0

40 to 100

6 to 14

0.7 to 10.0

70 to 1035

10 to 150

0.7 to 1.6

70 to 150

10 to 22

1.5 to 20.0

140 to 2070

20 to 300

1.5 to 3.5

150 to 300

20 to 50

Switch State

120 Vac

240 Vac

Full Load

8.0

5.1

Locked Rotor

48.0

30.6

3-3/4

(95)

1-1/16 (27)

13/16 (21)

1-3/16

(30)

HOLE FOR

1/2 INCH

CONDUIT

DIFFERENIAL

ADJUSTMENT

SCREW

1-1/2 (38)

2-1/8 (54)

M19635B

1-13/16

(46)

4-1/2 (115)

4-11/32 (111)

1-61/64 (50)

1-15/16 (49)

3/16 X 11/32

(5 X 9)

KNOCKOUT

MAIN SCALE

ADJUSTMENT

SCREW

1/4 –18 NPT

CLEAR

PLASTIC

COVER

3-7/8

(99)

2-3/4 (70)

3-1/4 (83)

DIMENSION

"A"

(SEE TAB)

1

1

1 15 TO 100 kPa (2 TO 15 PSI) SCALE MODELS ONLY.

PSI

RANGE

2 TO 15

5 TO 50

10 TO 150

20 TO 300

DIMENSION

"A"

123

126

126

146