L404F,T,V PRESSURETROL

®

CONTROLLERS

71-2429—06

6

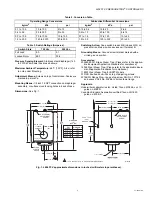

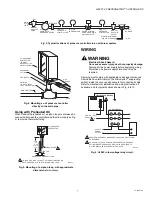

Fig. 7. L404F in a typical 2-wire control circuit.

Fig. 8. L404T,V terminal blocks and internal schematics.

Fig. 9. Hookup of an oil pressure controller used on a

single burner system with an integral oil pump.

Fig. 10. Hookup of an oil pressure controller used on a

single burner or multiburner system with an external oil

pump.

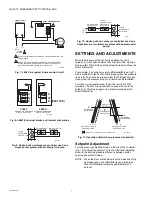

SETTINGS AND ADJUSTMENTS

When the pressure at the control rises above the L404

setpoint, a circuit opens between the R-B terminals. During a

pressure fall, R-B will close at the setpoint pressure minus the

switch differential.

For example, if a controller is set to differential

B

(see Fig.11)

with a controller setpoint of

A

, R-B will open when the pressure

rises to

A

. Then during a pressure fall, the R-B terminals will

close when the pressure drops to

C

(

A

minus differential

B

).

For make on rise applications, the switch is wired to R-W

terminals. The R-W circuit will close on pressure rise to the

setpoint. R-W will open again on a pressure drop past the

switch differential.

Fig. 11. Operation of switch on pressure rise and fall.

Setpoint Adjustment

Turn the pressure adjusting screw on the top of the controller

(Fig. 12) to adjust the setpoint. Turn the differential adjusting

screw to the desired pressure difference between switch

opening and switch closing.

NOTE: When the main scale setting is at the lower end of the

operating range, the differential range will be less

than the differential setting by approximately 20

percent.

M19638A

1

1

2

2

PROVIDE DISCONNECT MEANS AND OVERLOAD PROTECTION

AS REQUIRED.

AS SHOWN, SWITCH OPENS ON PRESSURE RISE. REVERSE

ACTING (MAKE ON PRESSURE RISE) UNITS ARE WIRED TO

R-W TERMINALS AND TERMINAL B IS OMITTED.

MOTOR

L404F PRESSURETROL

LINE VOLTAGE

THERMOSTAT

R

W

B

L1

(HOT)

POWER

SUPPLY

L2

L404T

BREAKS ON PRESSURE

RISE TO SET POINT

L404V

MAKES ON PRESSURE

RISE TO SET POINT

M1801B

B

R

W

R

W

B (OMITTED)

L2

OIL PRESSURE

CONTROLLER

MAIN OIL VALVE

SOLENOID

FLAME

SAFEGUARD

CONTROL

M9789

L2

L2

L1

(HOT)

OIL PRESSURE

CONTROLLER

FLAME

SAFEGUARD

CONTROL

OTHER

CONTROLLERS,

LIMITS, AND

INTERLOCKS

M9790

M19639B

B-R MAKES

(R-W BREAKS)

DIFFERENTIAL

(ADJUSTABLE)

B-R BREAKS

(R-W MAKES)

CONTROL

SET POINT

B R-W

B-R

SWITCH ACTION ON

PRESSURE RISE

INDICATES CLOSED SWITCH CONTACTS.

W

B-R

SWITCH ACTION ON

PRESSURE FALL

W

B R-W