L404F,T,V PRESSURETROL

®

CONTROLLERS

71-2429—06

4

INSTALLATION

When Installing This Product…

1.

Read these instructions carefully. Failure to follow them

could damage the product or cause a hazardous

condition.

2.

Check on the ratings given in the instructions and

marked on the product to make sure the product is

suitable for your application.

3.

Installer must be a trained, experienced service

technician.

4.

After installation is complete, check out the product

operation as provided in these instructions.

IMPORTANT

When making pipe connections, use pipe dope

sparingly to seal the joints; any excess dope may clog

the small hole in the fitting and prevent the controller

from operating properly.

Location and Mounting (L404F)

Locate the L404F where the ambient temperature will not

exceed 66°C (150°F). The L404F can be mounted near the

pressure gauge, at a remote location, in a fitting provided by

the boiler manufacturer, or in a special mounting on low water

cutoffs. The L404F should always be mounted above the water

line in steam boiler applications.

NOTE: For accurate operation, supplemental heat should be

added to installations where temperatures fall below

-29°C (-20°F).

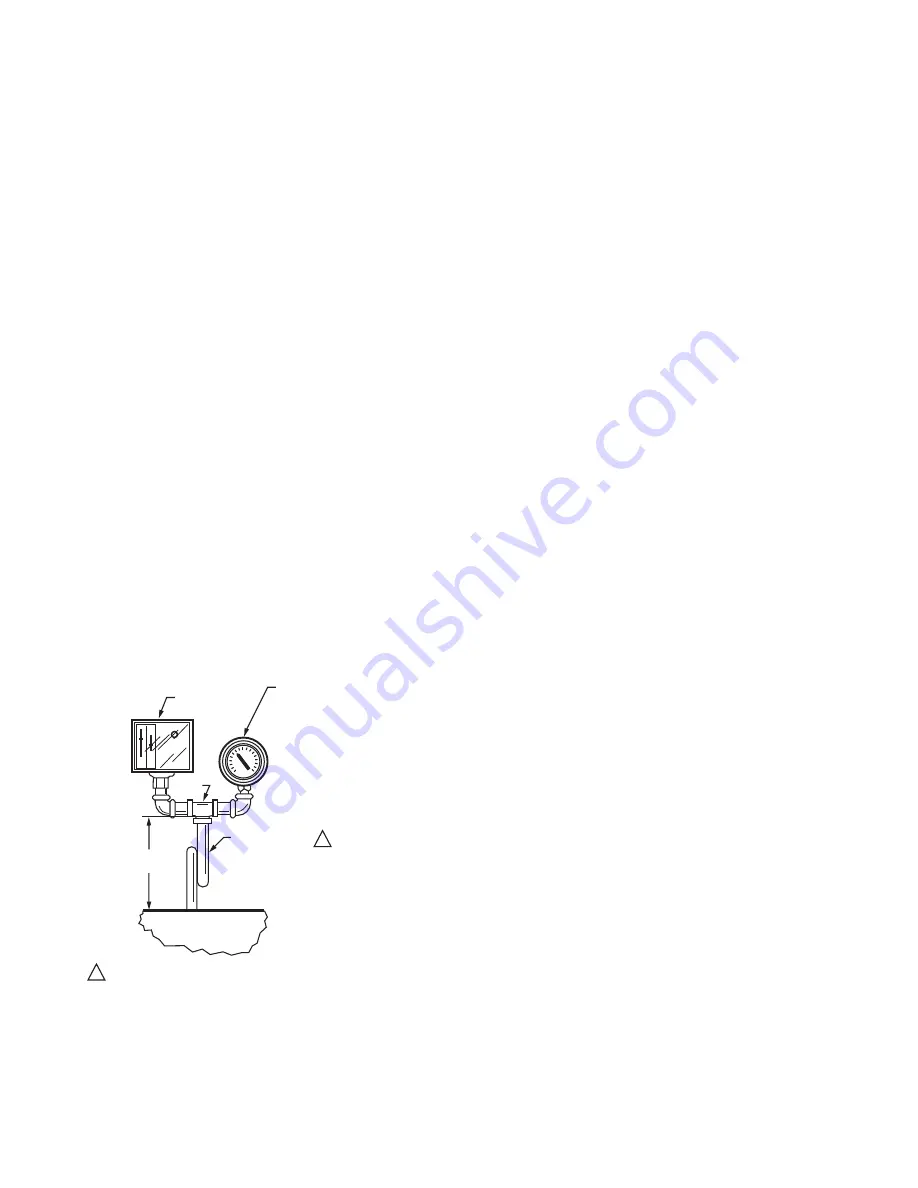

A steam trap must be connected between the L404F and the

boiler (see Fig. 2) to prevent boiler scale and corrosive vapors

from attacking the elbows or diaphragm.

Fig. 2. Steam trap mounting.

Pressure Gauge Mounting

To mount beside a pressure gauge, remove the gauge, and

install in its place the steam trap with a tee on top. Mount the

PressureTrol

®

unit and pressure gauge on the side of the tee

by means of nipples and elbows (see Fig. 2).

Remote Mounting

Excessive vibration at the boiler may affect the operation of the

L404F. In these cases, the L404F should be remotely located,

subject to the following:

1.

All piping must be suitable and properly pitched to drain

all condensation back to the boiler.

2.

The remote mounting must be solid.

3.

A steam trap must be used at one end of the piping.

Boiler Mounting

If it is not convenient to mount the L404F adjacent to the

pressure gauge, install a steam trap at the location

recommended by the boiler manufacturer, then screw the

device directly to the steam trap.

Location and Mounting (L404T,V)

Location

NOTE: For most accurate operation, supplemental heat

should be added to installations where the

temperature falls below -20°F (-29°C).These

controllers can be mounted at any location in the oil

supply line, depending on the application. Typical

locations are shown in Fig. 3. The low oil pressure

controller should be located upstream from the safety

shutoff valve(s). In a downstream location, there

would be zero pressure when the burner is not

running and the safety shutoff valve(s) is (are) closed.

This could prevent startup or require manual reset

every time the burner is started. The high oil pressure

controller should be located as near to the burner as

possible.

Mounting

Mount the oil pressure controller directly on the main pipe.

Insert a tee in the pipe line, and connect a pipe nipple of

appropriate size to the tee (see Fig. 4). Screw the hexagonal

fitting (1/4-18 NPT internal thread) of the pressure controller to

the pipe nipple. To avoid leaks and damage to the case, use a

parallel jaw wrench on the hexagonal fitting close to the pipe

nipple. Do not tighten the pressure controller by hand by

holding the case.

Make all pipe connections in accordance with approved

standards. Use only a small amount of pipe compound to seal

the connection joints. Excess pipe compound may clog the

orifice in the pipe fitting and prevent the controller from

operating properly.

4-1/2 TO 5-1/2

(114.3 TO 139.7)

BOILER

STEAM TRAP

(SIPHON LOOP)

TEE

PRESSURE

GAUGE

PRESSURE

CONTROLLER

M23885

1

1 1/4 IN. PIPE WITH 1/4 - 18 NPT EXTERNAL THREADS

ON BOTH ENDS AND 2-1/4 IN. DIAMETER LOOP.